Performance test device for multifunctional fans

A test device and multi-functional technology, applied in the direction of mechanical equipment, machine/engine, pump control, etc., can solve the problem of single test flow, etc., and achieve the effect of wide application objects, strong reconfigurability, and various functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below with reference to the accompanying drawings and examples.

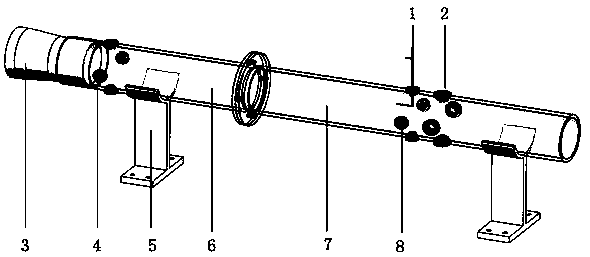

[0020] Such as figure 1 A multifunctional fan performance test device shown in , includes a measuring port 3, a front air cylinder 6, and a rear air cylinder 7; the measurement port 3, the front air cylinder 6, and the rear air cylinder 7 are connected in sequence. The measuring port 3 and the front air cylinder 6 are connected through an interference fit between parts, and the other side of the measuring port 3 is also connected with the test piece through an interference fit. The performance test of fans of different sizes can be realized by replacing different measuring ports 3 .

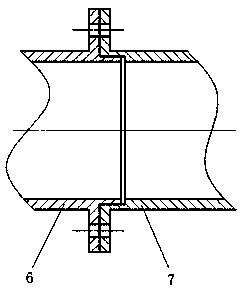

[0021] figure 2 The middle front air cylinder 6 and the rear air cylinder 7 are positioned circumferentially through the L-shaped interface, and are positioned axially through the four bolts at the flange, which ensures a certain sealing performance and ensures tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com