A kind of cross-linkable flame-retardant fluorine-containing silicone oil, its preparation method and flame-retardant release coating

A technology of fluorine-containing silicone oil and coatings, applied in the direction of fireproof coatings, coatings, etc., can solve the problems of not being environmentally friendly and unfavorable to the environment, and achieve good flame retardancy and improve the effect of flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) Preparation of crosslinkable flame retardant fluorine-containing silicone oil:

[0034] Under nitrogen protection, 25g of perfluorobutylethylene as perfluoroalkylethylene, 35g of glycidyl methacrylate and 20g of allyl phosphate and 100g of hydrogen-containing silicone oil (molecular weight at 9000 Hydrogen-containing silicone oil with a hydrogen content of 0.8%) (Foshan Huagu Organic Silicon Co., Ltd.) was mixed to obtain a mixed solution 1;

[0035] 25g perfluorobutylethylene, 35g glycidyl methacrylate and 20g allyl phosphate were mixed with 0.25g Karstedt catalyst (1,3-divinyl-1,1,3,3-tetramethyldisiloxane Platinum (0), Pt, 2% xylene solution) were mixed and placed in an environment of 70°C for activation to obtain a mixed solution 2;

[0036] After activation, slowly drop the mixed solution 2 into the mixed solution 1; heat up to 100°C and react for four hours. The unreacted small molecules in the product were removed by suction filtration to obtain a cross-lin...

Embodiment 2

[0039] Under the protection of nitrogen, 35g of perfluoroalkylethylene, 45g of epoxy-containing substances and 28g of allyl phosphate were mixed with 200g of hydrogen-containing silicone oil to obtain a mixed solution 1;

[0040] Mix 35g of perfluoroalkylethylene, 45g of epoxy-containing substances and 28g of allyl phosphate with 8g of platinum catalyst and put them into an environment of 70°C for activation to obtain mixed solution 2;

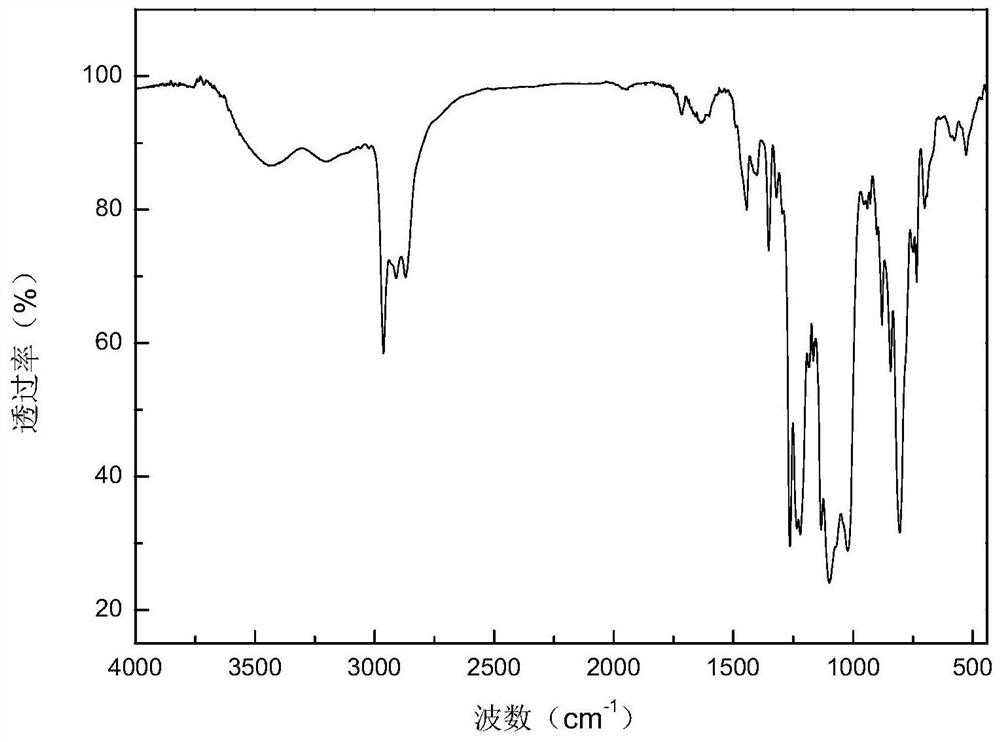

[0041] After activation, slowly drop the mixed solution 2 into the mixed solution 1; heat up to 100°C and react for four hours. The unreacted small molecules in the product were removed by suction filtration to obtain a cross-linkable flame-retardant fluorine-containing silicone oil, and its infrared spectrum was as follows: figure 1 shown.

[0042] Among them, the perfluoroalkylethylene is perfluorohexylethylene, the epoxy-containing substance is allyl glycidyl ether, the allyl phosphate is allyl dimethyl phosphate, and the hydrogen-containi...

Embodiment 3

[0045] Under the protection of nitrogen, mix 30g of perfluoroalkylethylene, 15g of epoxy group-containing substances and 10g of allyl phosphate with 180g of hydrogen-containing silicone oil to prepare mixed solution 1;

[0046] Mix 30g of perfluoroalkylethylene, 15g of epoxy-containing substances and 10g of allyl phosphate with 5g of platinum catalyst and put them into an environment of 70°C for activation to obtain mixed solution 2;

[0047] After activation, slowly drop the mixed solution 2 into the mixed solution 1; heat up to 100°C and react for four hours. Remove unreacted small molecules in the product by suction filtration, cross-linkable flame retardant fluorine-containing silicone oil.

[0048] Among them, the perfluoroalkylethylene is perfluorohexylethylene, the epoxy-containing substance is allyl glycidyl ether, the allyl phosphate is allyl dimethyl phosphate, and the hydrogen-containing silicone oil has a molecular weight of 9000 and a hydrogen content of 0.35% hy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com