Five-degree-of-freedom stacking mechanical arm capable of automatically sorting and discharging material

An automatic sorting and manipulator technology, applied in the direction of sorting, object stacking, object destacking, etc., can solve the problems of endangering the safety of operators, affecting production efficiency, error-prone, etc., to increase production efficiency and not easy to operate Safe and error-prone effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

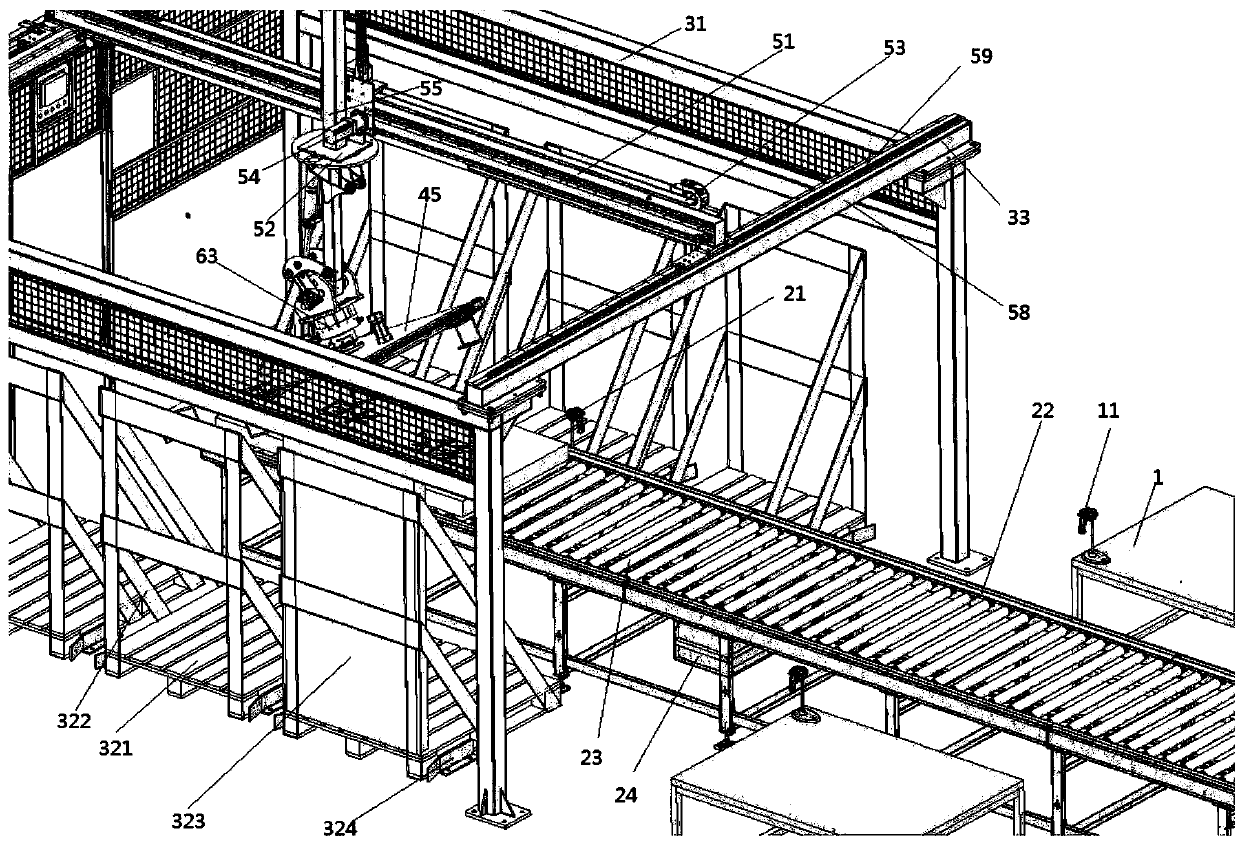

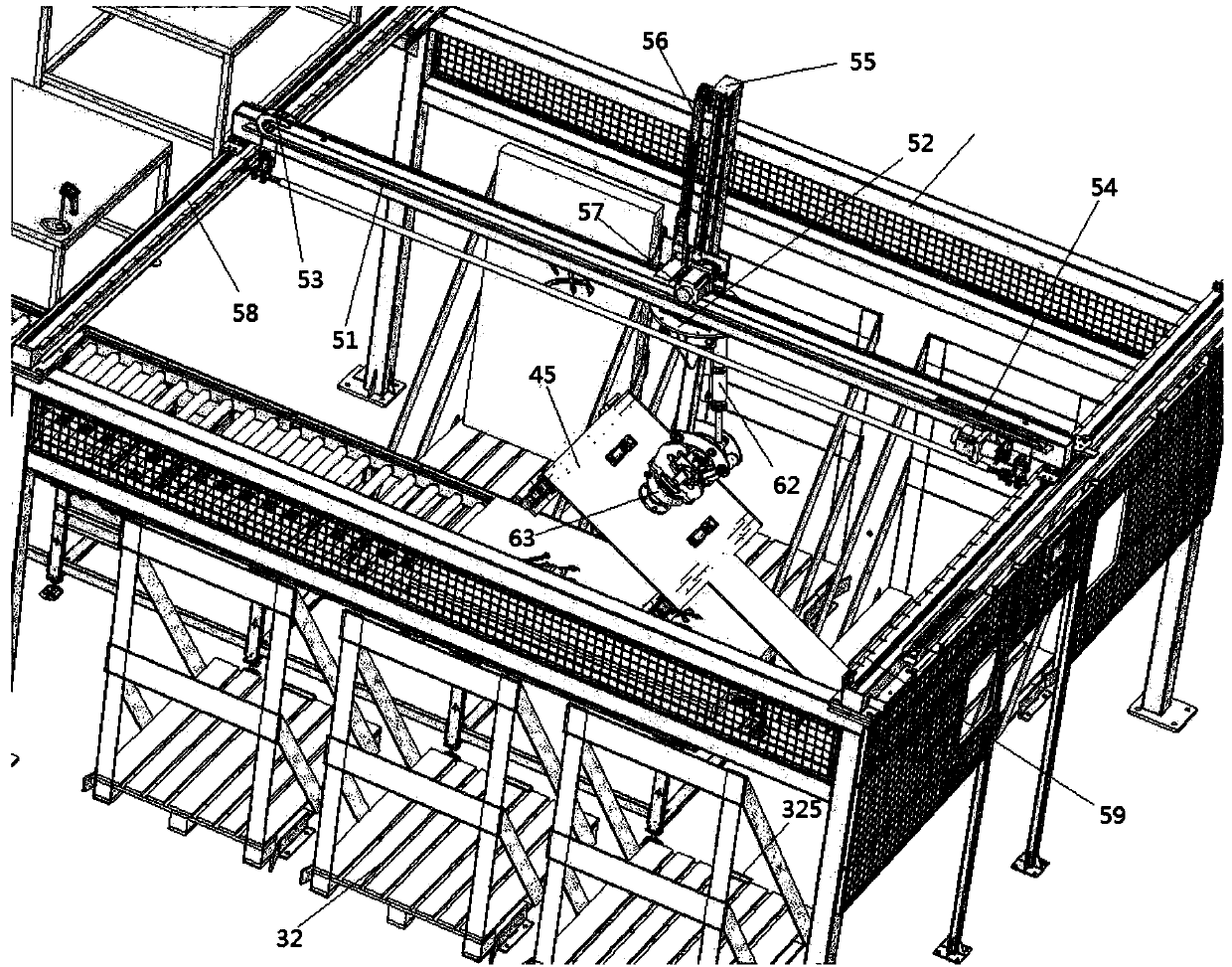

[0045] Embodiment 1, a palletizing manipulator with five degrees of freedom for automatic sorting and blanking, such as figure 1 As shown, it includes a frame 31 on the right side, a transmission mechanism 2 in the middle, and a placement table 1 on the left side. There are several placement tables 1 arranged in a row around the two sides of the transmission mechanism 2. On the placement table 1 close to the transmission mechanism 2 All are equipped with code scanning parts 11. The conveying mechanism 2 is arranged horizontally and extends from the placement table 1 to the frame 31, and can transport the cartons on the placement table 1 to the frame 31 for sorting and stacking.

[0046] Such as figure 2 with image 3 As shown, the sending mechanism includes a transmission frame 22, which extends from the position of the placement table 1 to the middle of the frame 31. The transmission frame 22 is also provided with several parallel transmission rollers 23, and the transmiss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com