Sand cleaning mechanism for sand mold sleeve box

A technology of sand mold casing and sand cleaning machine, which is applied in the direction of mold boxes, casting molding equipment, tools, etc., can solve the problems of high labor intensity and low production efficiency, achieve reasonable structural design, reduce costs, and improve sand cleaning efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example

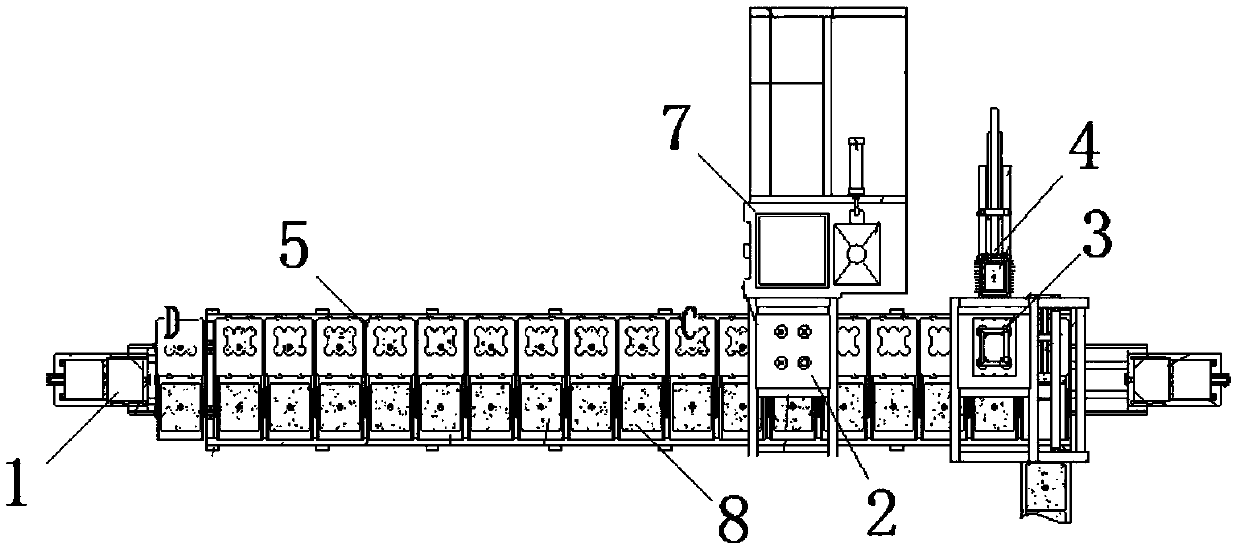

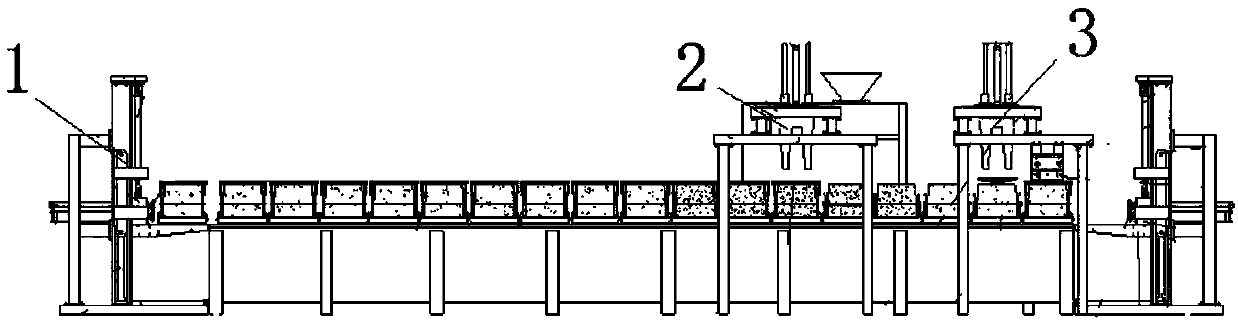

[0052] The preferred specific examples of the sand box removal mechanism are as follows:

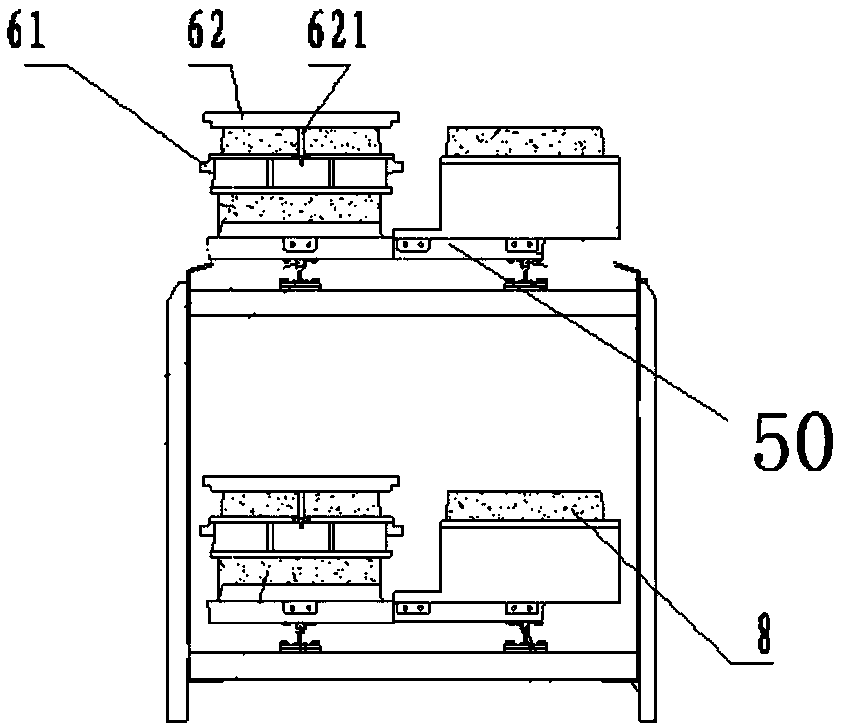

[0053] The case removal mechanism 3 is associated with a kind of duplex linear casting production frame and the upper column track. Case removal mechanism 3 mainly includes case removal frame 311, installation frame I 312, support top frame 315, positioning frame 317, case removal lifting cylinder 334, sand mold off-line work cylinder 323, unpacking bracket 336, and off-line push head 326 , the connecting plate 316 between the case removal frame 311 and the support top frame 315 is connected and fixed.

[0054] The support top frame 315 and the installation frame II 314 are provided with a casing removal lifting cylinder 334 and a guide sleeve III 332, and the casing removal lifting cylinder 334 and the lower end of the lifting cylinder guide rod 331 are connected with an unpacking bracket seat 335; 335 is equipped with unpacking bracket 336 respectively on both sides parallel to the tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com