Novel peening hammer of impact crusher

An impact crusher and impact hammer technology, which is applied in the field of mining machinery, can solve the problems of damage to other parts, poor crushing effect, and small contact area, and achieve uniform wear, good crushing effect, and good impact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

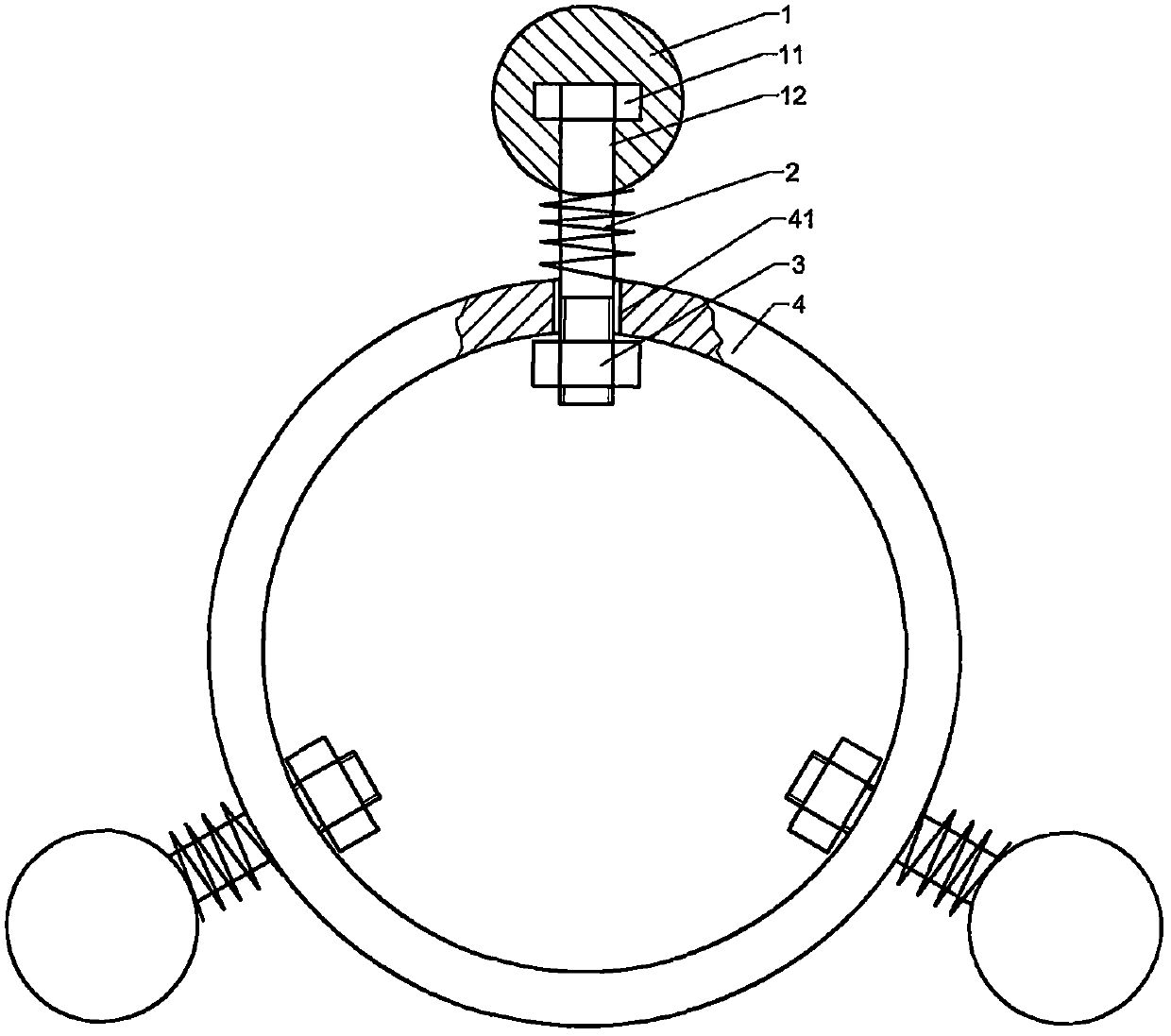

[0018] As shown in the figure, a new type of impact hammer for an impact crusher includes a hammer body 1 and a ring body 4, the ring body 4 is in the shape of a ring, and the ring body 4 is uniformly distributed with three round holes 41 in the radial direction ; The hammer body 1 includes a striking ball 12 and a bolt 11, the striking ball 12 is spherical and cast together with the head of the bolt 11; the stem of the bolt 11 passes through the circular hole 41 from the outside to the inside , form a threaded connection with the nut 3. The nut 3 and the bolt 11 are spot-welded to prevent loosening, which effectively solves the problem of preventing loosening under vibration, and the hammer body 1 will not fall off from the ring body 4 . After the hammer body 1 is worn out, the bolt 11 is directly sawed off, and then a new hammer body is replaced. The length of the bolt shank between the outer circle of the hitting ball 12 and the outer circle of the ring body 4 is changed b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com