A filter device for reducing liquid rocket motor liquid flow test excess

A liquid rocket and filter device technology, applied in filtration and separation, fixed filter element filters, separation methods, etc., can solve problems such as affecting the validity of test data, affecting product reliability, inability to seal the pool, etc., to prevent impurities from entering the product. Internal, enhanced fluid stability, easy installation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The invention proposes a filter device for reducing the excess in liquid rocket engine high pressure (pressure up to 5-6MPa) high flow rate (inlet flow rate is 10m / s) liquid flow test.

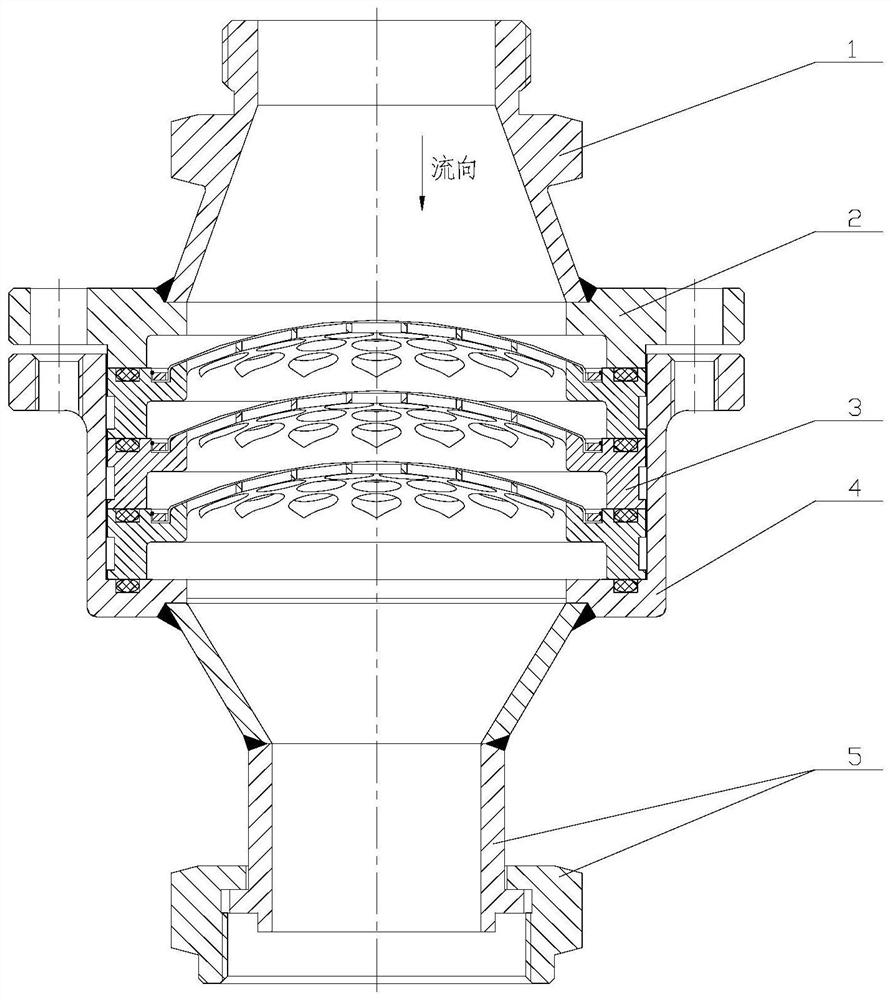

[0024] Such as figure 1 As shown, the present invention includes a first pipeline end 1 , an end cover 2 , a filter assembly 3 , a housing 4 and a second pipeline end 5 .

[0025] One end of the first pipeline end 1 is connected to the outlet of the system filter, and the other end is sealed to the end cover 2; one end of the second pipeline end 5 is connected to the product, and the other end is sealed to the housing 4, and the filter assembly 3 is installed on In the housing 4, the end cover 2 and the housing 4 are connected by fasteners, and the end cover 2 compresses the filter assembly 3; between the filter assembly 3 and the end cover 2, and between the filter assembly 3 and the housing 4 are sealed The ring is sealed.

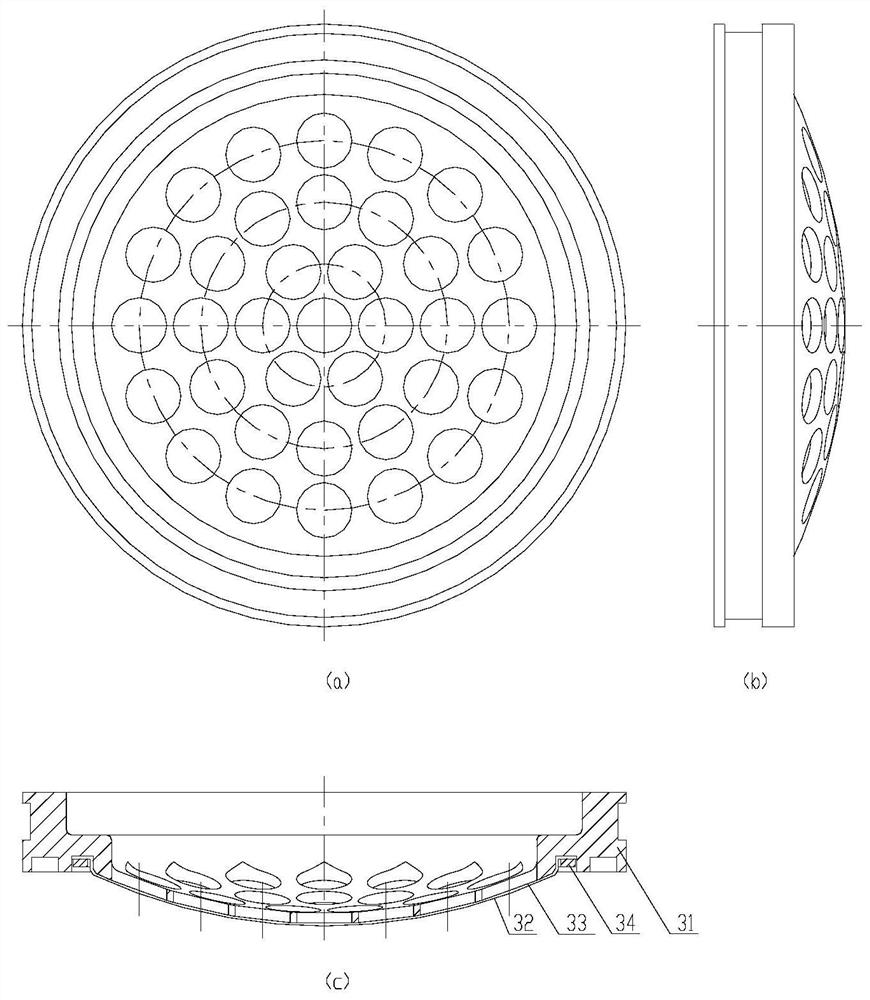

[0026] The filter assembly 3 is used to filter the tiny ex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com