Sample environment coupling loading device for neutron scattering

A loading device, a technology of neutron scattering, applied in the direction of applying stable tension/compression to test the strength of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

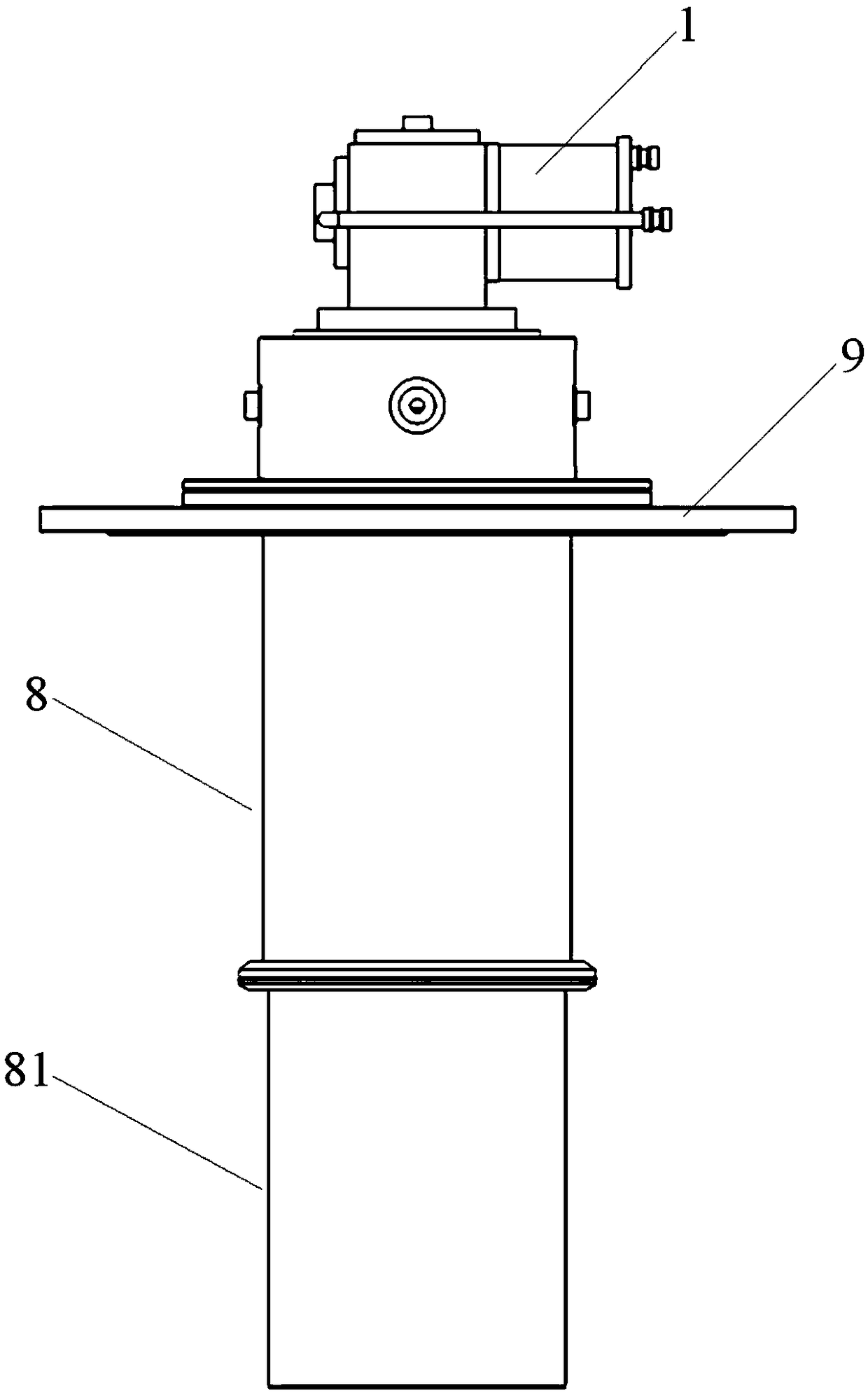

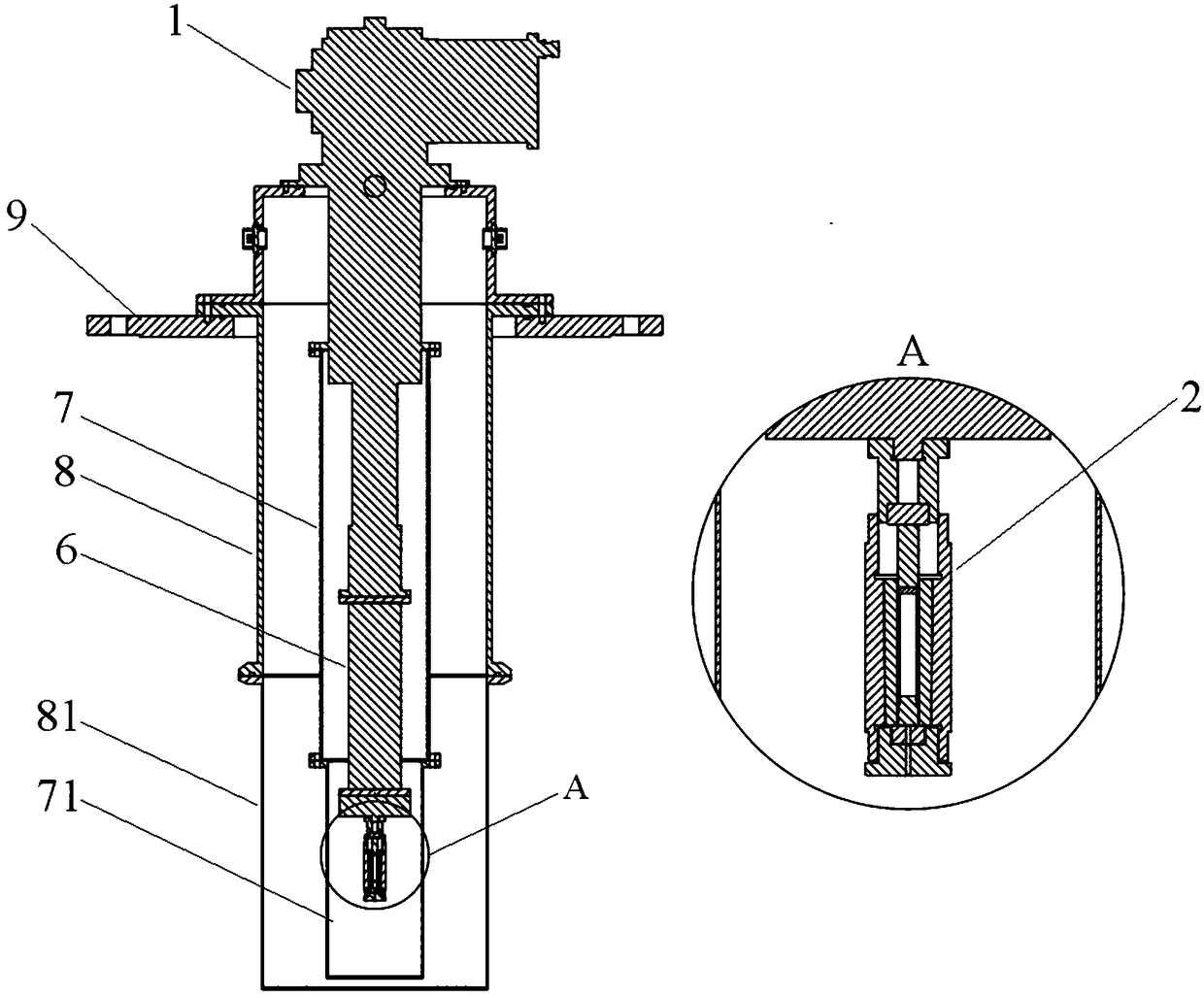

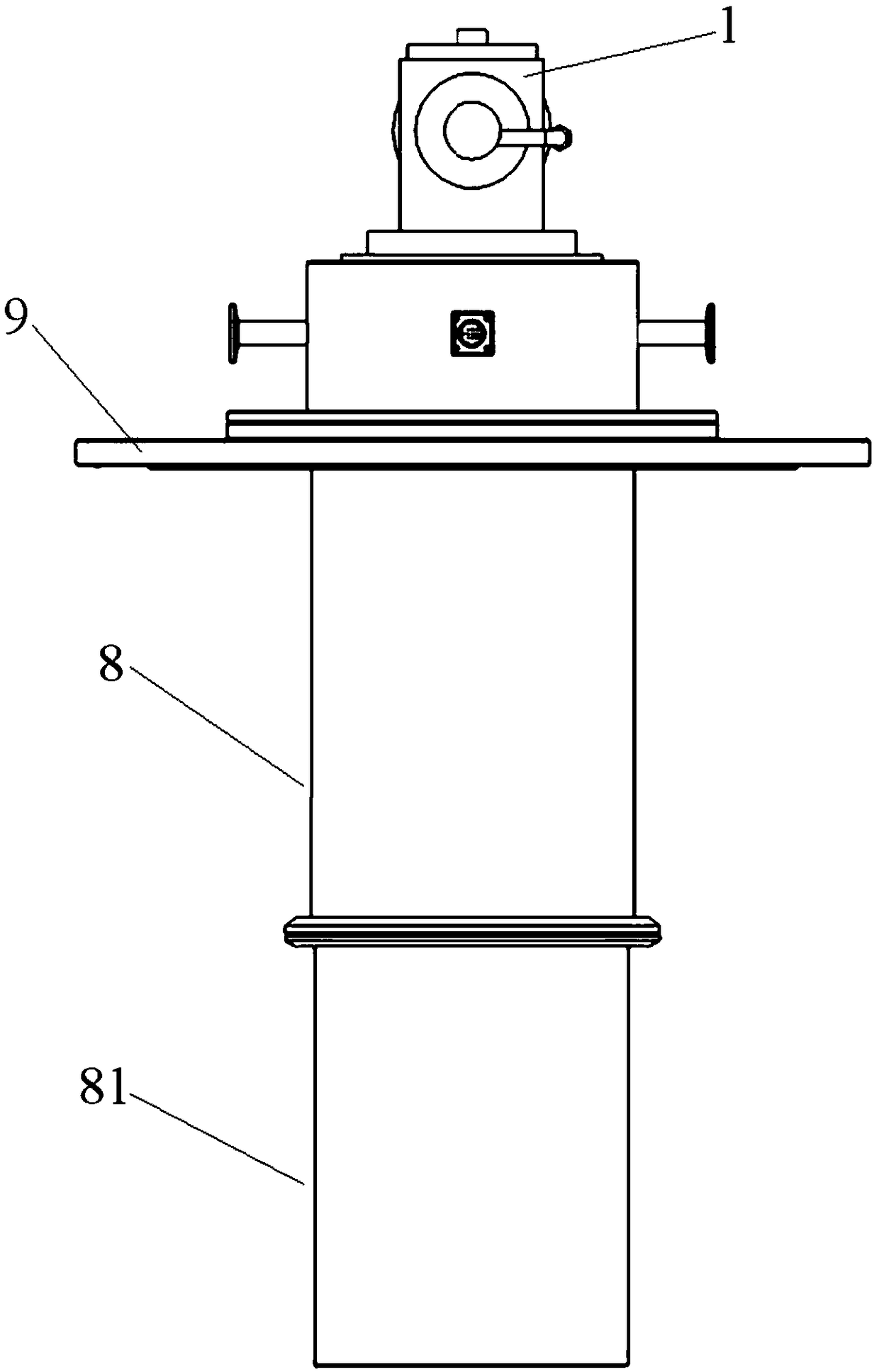

[0042] This example is used for the sample environment coupling loading device for neutron scattering, such as Figure 1 to Figure 7 As shown, it includes a G-M refrigerator 1 , a high-pressure sample chamber 2 , a sample tube 3 and a piston 4 . Wherein, the high-pressure sample chamber 2 includes an outer cylinder 21 and an inner cylinder 22, the outer cylinder 21 is open at both ends, and internal threads are provided on the inner wall of the opening; the inner cylinder 22 is open at both ends, and the inner cylinder 22 is inserted into the outer cylinder 21, and The latter is a cylindrical structure with an interference fit. In this example, the combined assembly of the inner cylinder 22 and the outer cylinder 21 is the core part of the high-pressure sample chamber, and the outer surface of the inner cylinder 22 and the inner surface of the outer cylinder 21 are respectively finished according to a taper of 1:50 for static fit and precise positioning And the inner and oute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com