Kerb auxiliary mounting equipment

A technology for installing equipment and curb stones, which is applied in the field of auxiliary installation equipment for curb stones, can solve the problems of failure to place curb stones and low efficiency, and achieves the effects of simple structure, improved efficiency and high work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

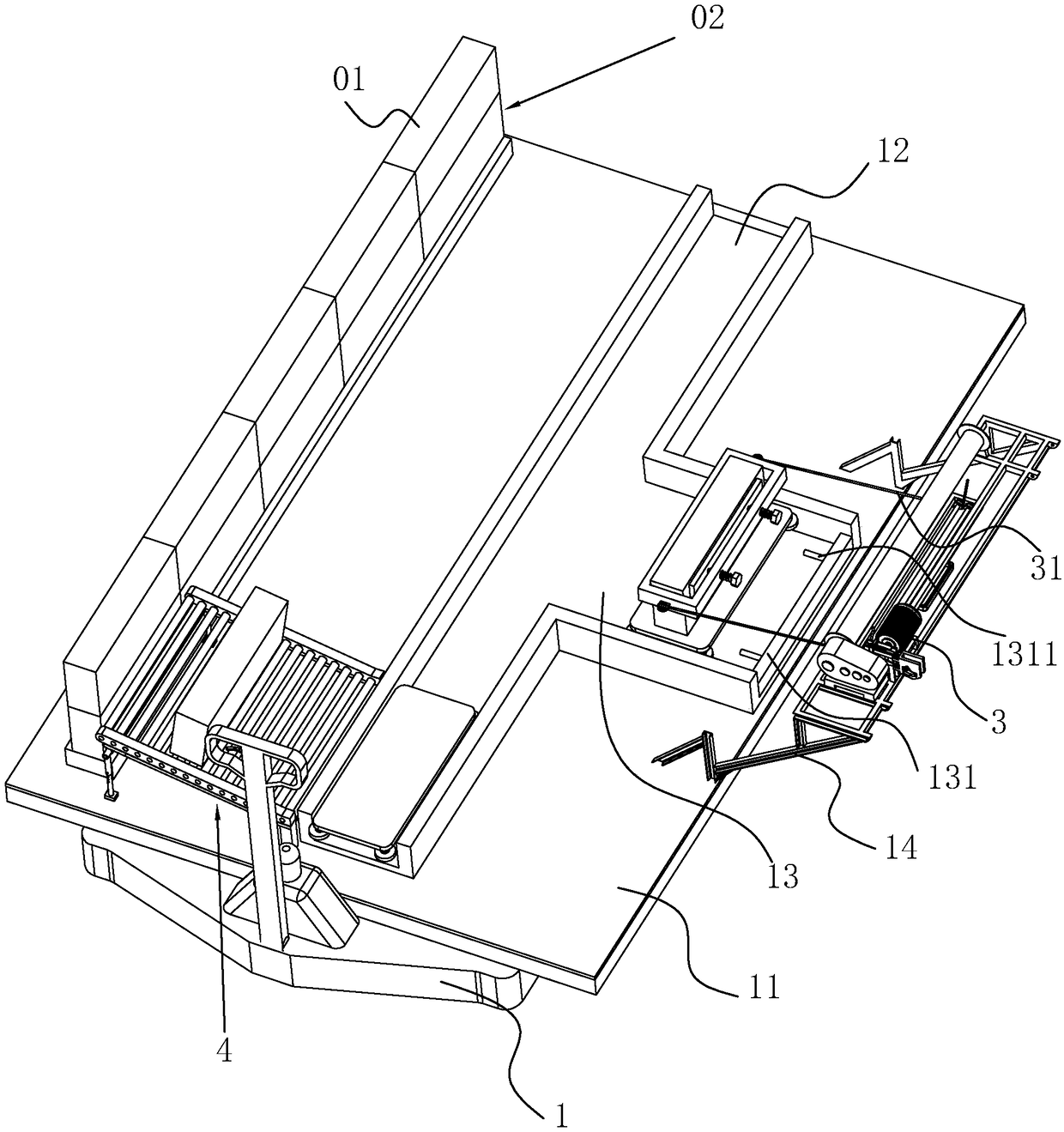

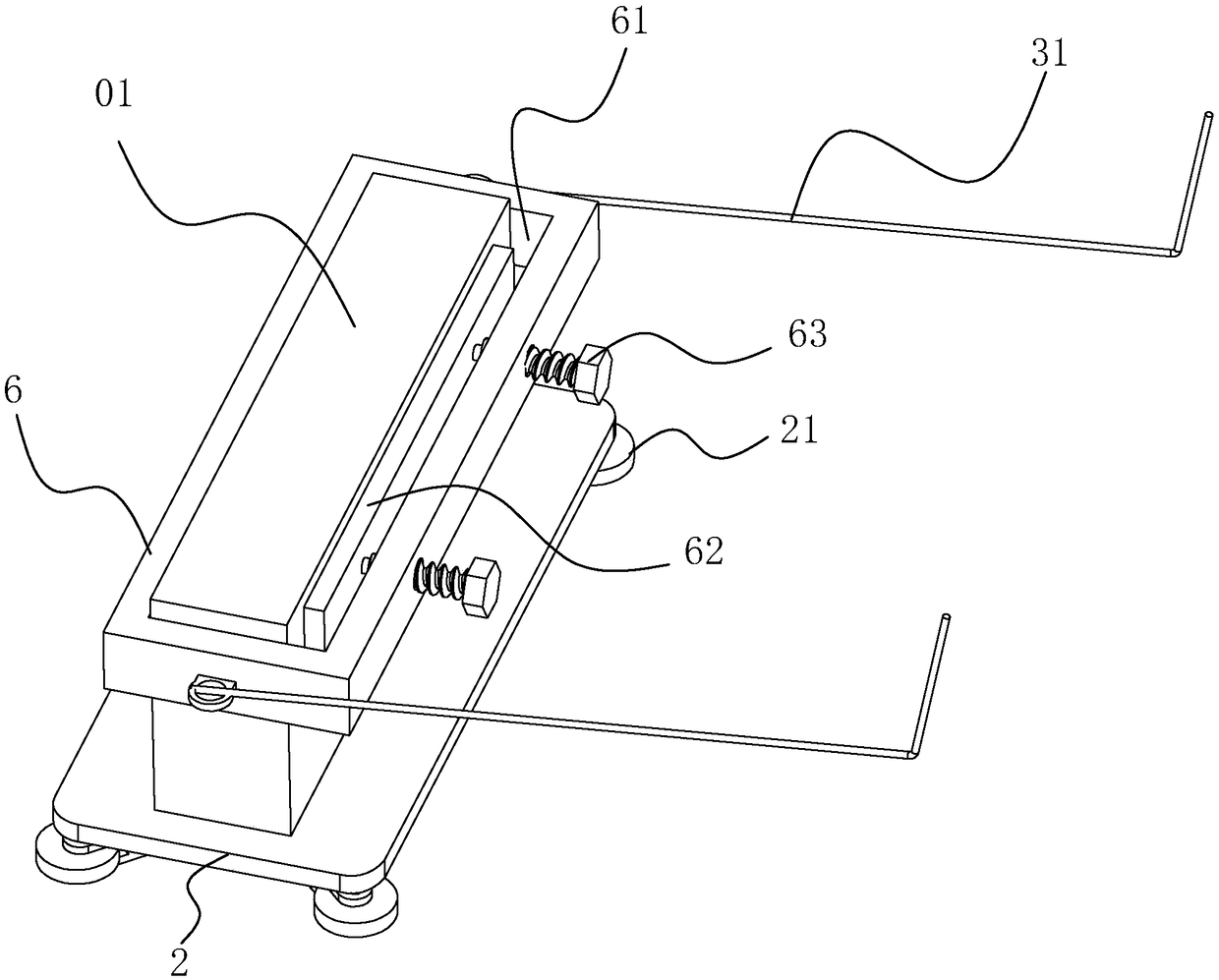

[0036] A curb stone 01 auxiliary installation equipment, refer to figure 1 , including a manual hydraulic vehicle 1, a horizontal pallet 11 is arranged on the manual hydraulic vehicle 1, and a curb stack 02 is arranged on the left side along the forward direction of the pallet 11, and the curb stones 01 are neatly stacked and placed on the curb stack 02 position; vertical chute 12 is provided on the right side of the pallet 11 advancing direction perpendicular to the entire row of curb stacks 02, and a horizontal chute 13 is vertically provided in the middle of the vertical chute 12, and the vertical chute The groove 12 and the horizontal chute 13 communicate with each other; between the curb stack 02 and the vertical chute 12, a sliding ramp 4 is provided, and the sliding ramp 4 can move the curb 01 from the curb stack 02 to the vertical In the chute 12; on the end of the horizontal chute 13 away from the vertical chute 12, a hoist 3 is provided, and the hoist 3 is fixedly in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com