Light swap tank-type container and assembling method thereof

A technology for exchanging tanks and containers, which is applied in the field of light-duty exchange tank containers and their assembly, which can solve the problems of overweight frames, low weight, and prolonged production cycles, and achieve the advantages of improved transportation efficiency, convenient assembly, and long service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below with reference to the accompanying drawings and specific embodiments, but it is not intended to limit the present invention.

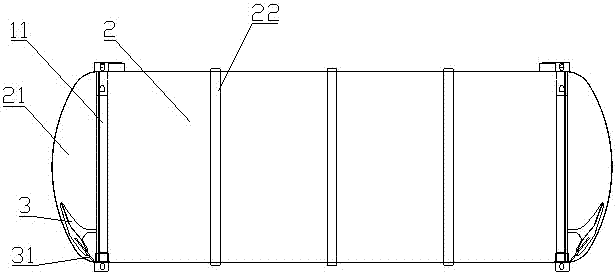

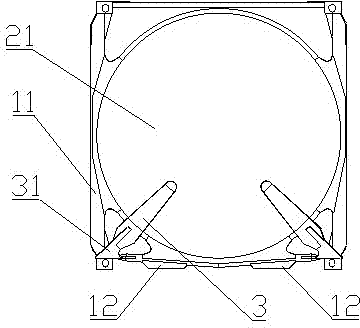

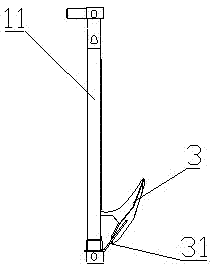

[0023] like Figure 1 to Figure 4 As shown, an embodiment of a light-weight exchange tank container of the present invention includes a frame with a pair of end frames 11, and a tank body 2 installed in the frame. Both ends of the tank body 2 include hemispherical heads 21. The tank body 2. The heads 21 at both ends protrude out of the end frame 11 of the frame, wherein the end corners of the end frame 11 are provided with claws 3 extending outward and toward the center of the head 21, and the inner sides of the claws 3 are attached and fixed to the head 21 hemispherical surface.

[0024] The principle of the above technical solution is that the longitudinal movement of the tank body 2 relative to the frame is restricted by the claw 3 connected with the end frame 11 of the frame. The overal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com