A Foldable Capturing Metamorphic Mechanism Based on Constrained Helix

A metamorphic mechanism and spiral technology, which is applied in the field of foldable and catching metamorphic mechanisms, can solve the problems of poor overall rigidity of the mechanism, inappropriate objects, and limited range of captured objects, and achieve the effect of reducing quality and burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

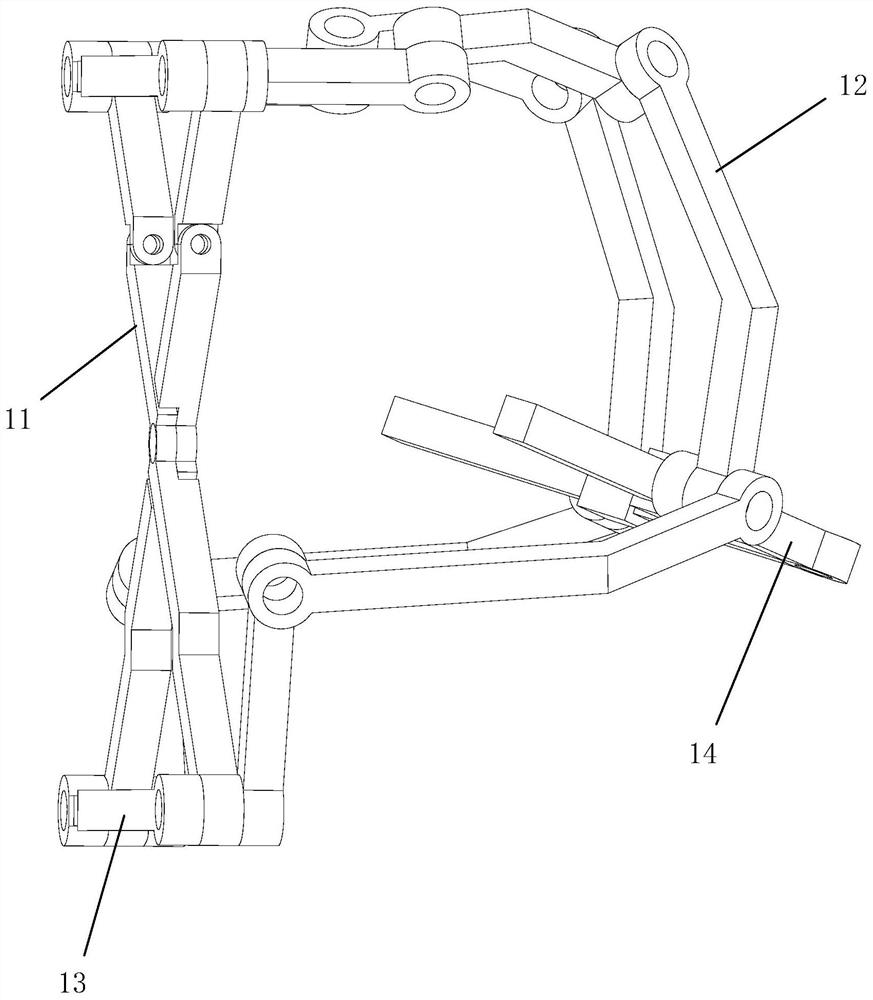

[0053] This embodiment provides a metamorphic unit, such as Figure 1-4 As shown, it includes: a catch mechanism 11, a rotating branch mechanism 12, a telescopic branch mechanism 13, and a hinge mechanism 14.

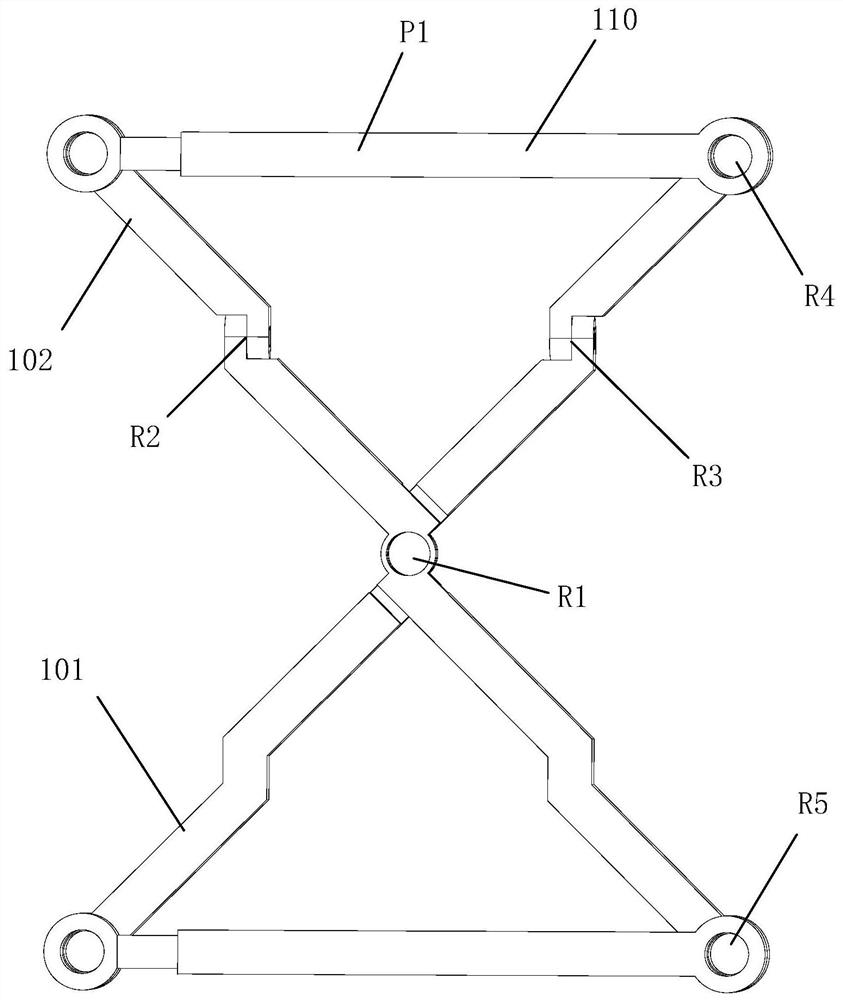

[0054] Wherein, the catching mechanism 11 comprises two identical scissor bars 101 and two identical connecting rods 102, and the two scissor bars 101 are connected to each other by the rotating pair R1 to form a scissor mechanism; the bottom ends of the two connecting rods 102 They are respectively connected to the tops of the two scissor bars 101 through the rotating pair R2 and the rotating pair R3; the catching mechanism forms a catching surface for the catching process. The rotation pair R2 and the rotation pair R3 provide the degree of freedom for the capture surface to perform capture movement.

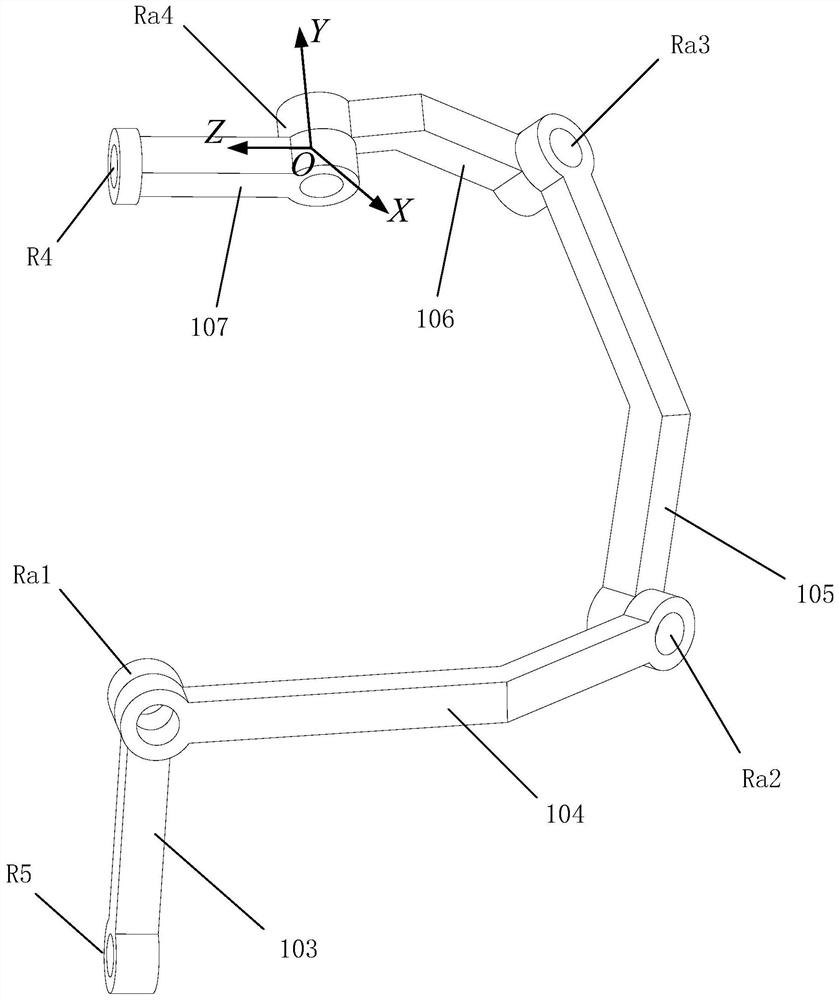

[0055] Two identical rotating branch mechanisms 12, the rotating branch mechanism 12 comprises the first rotating rod 103, the second rotating rod 104, the third rotati...

Embodiment 2

[0071] This embodiment provides a kind of foldable grasping mechanical arm, such as Figure 5-7 As shown, it includes four identical metamorphic units 201 (the metamorphic units 201 here have the same structure as the metamorphic units in Embodiment 1, which will not be repeated here), and the adjacent metamorphic units 201 branch Mechanism 202 is connected; the telescopic branch mechanism 202 is a hybrid mechanism composed of four rotating pairs and two sliding pairs and is connected in series. After the two scissor bars 203 of each cell-changing unit 201 undergo a folding movement, the mechanical arm will be fully unfolded. At this time, the scissor bars 203 and the connecting rod 204 in the cell-changing unit 201 will perform an overturning motion, That is, the entire robotic arm will perform a capture movement.

Embodiment 3

[0073] This embodiment provides a foldable catch mechanism, such as Figure 8-10 As shown, it includes a chassis 301, four foldable grasping manipulators formed by adopting a metamorphic unit 302 (the metamorphic unit 302 here has the same structure as the metamorphic unit in Embodiment 1, and will not be described in detail here). 303 , four mechanical arms 303 are arranged on the chassis 301 in a circular array.

[0074] The rigid and expandable capture mechanism has three states of folding, stretching, and capture, and different states are used in different situations to complete the capture task in space. The rigid and expandable capture mechanism is put into the launch vehicle in a folded state, and then unfolded in space to perform the task of capturing a designated target.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com