Glue applying and powder scattering type hot-press composition device

A technology of lamination device and composite device, applied in the direction of lamination device, lamination, layered products, etc., can solve the problems of low efficiency of production equipment, low yield, poor reliability, etc., so as to improve production efficiency and improve yield , good reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

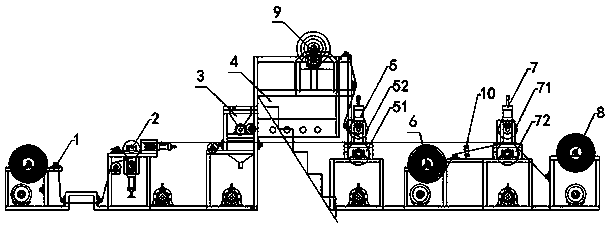

[0011] Depend on figure 1 Known, a kind of hot-pressing composite device of glue-coating and dusting, is characterized in that: comprises cloth layer unwinding mechanism 1, scraping device 2, powder-spreading device 3, heating device 4, pressing device I5, film layer unwinding mechanism 6 , pressing device II7 and winding device 8; the cloth unwinding mechanism 1, scraping device 2, powder spreading device 3, heating device 4, pressing device I5, film layer unwinding mechanism 6, pressing device II7 And the winding device 8 is connected in sequence; the top of the heating device 4 is provided with a paper layer unwinding mechanism 9; the scraping device 2, the powder spreading device 3, the pressing device I5, the pressing device II7 and the winding device 8 are equipped with driving devices; the cloth supplied by the cloth layer unwinding mechanism 1 is glued to the lower surface by the scraping device 2, and the hot melt powder is sprinkled on the upper surface by the powder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com