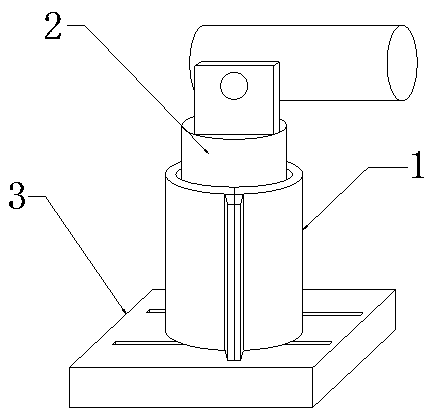

Protection mechanism of industrial mechanical arm

A protection mechanism and industrial machinery technology, applied in manipulators, manufacturing tools, etc., can solve the problems of weak impact resistance, insufficient protection, high maintenance cost, etc., and achieve high reliability, good protection effect and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

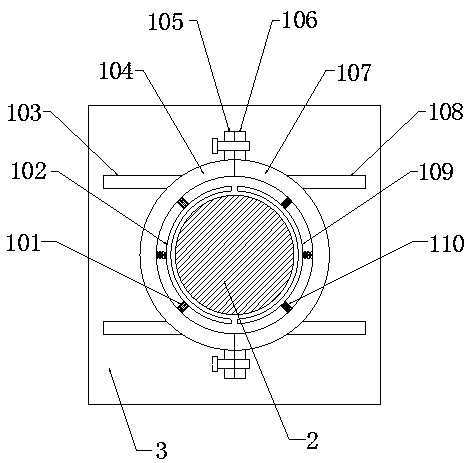

[0018] Specific implementation method: when in use, the operator pushes the protective plate 104 to the right, and the protective plate 104 drives the slider 1 to move in the guide groove 103, and then the protective plate 104 moves to the right on the installation base 3, and the protective plate 1 moves to the right. 104 moves to drive the rubber pad 1 102 to move. When the rubber pad 102 is closely attached to the mechanical arm body 2, stop pushing the protective plate 1 104, and push the protective plate 2 107 to the left, and the protective plate 2 107 drives the slider 2 to guide The second slot 108 moves to the left, and then the second protective plate 107 moves on the installation base 3. The second protective plate 107 moves to the right and drives the second rubber pad 109 to move to the left. When the second rubber pad 109 is closely attached to the outer surface of the mechanical arm body 2 Finally, stop pushing the protective plate two 107, and the connecting pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com