Air nailer

A nail gun and chamber technology, applied in the field of nail guns, can solve the problems of insufficient impact force of the nail gun, unfavorable miniaturization of the nail gun, poor nail driving effect, etc., and achieve good nail driving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

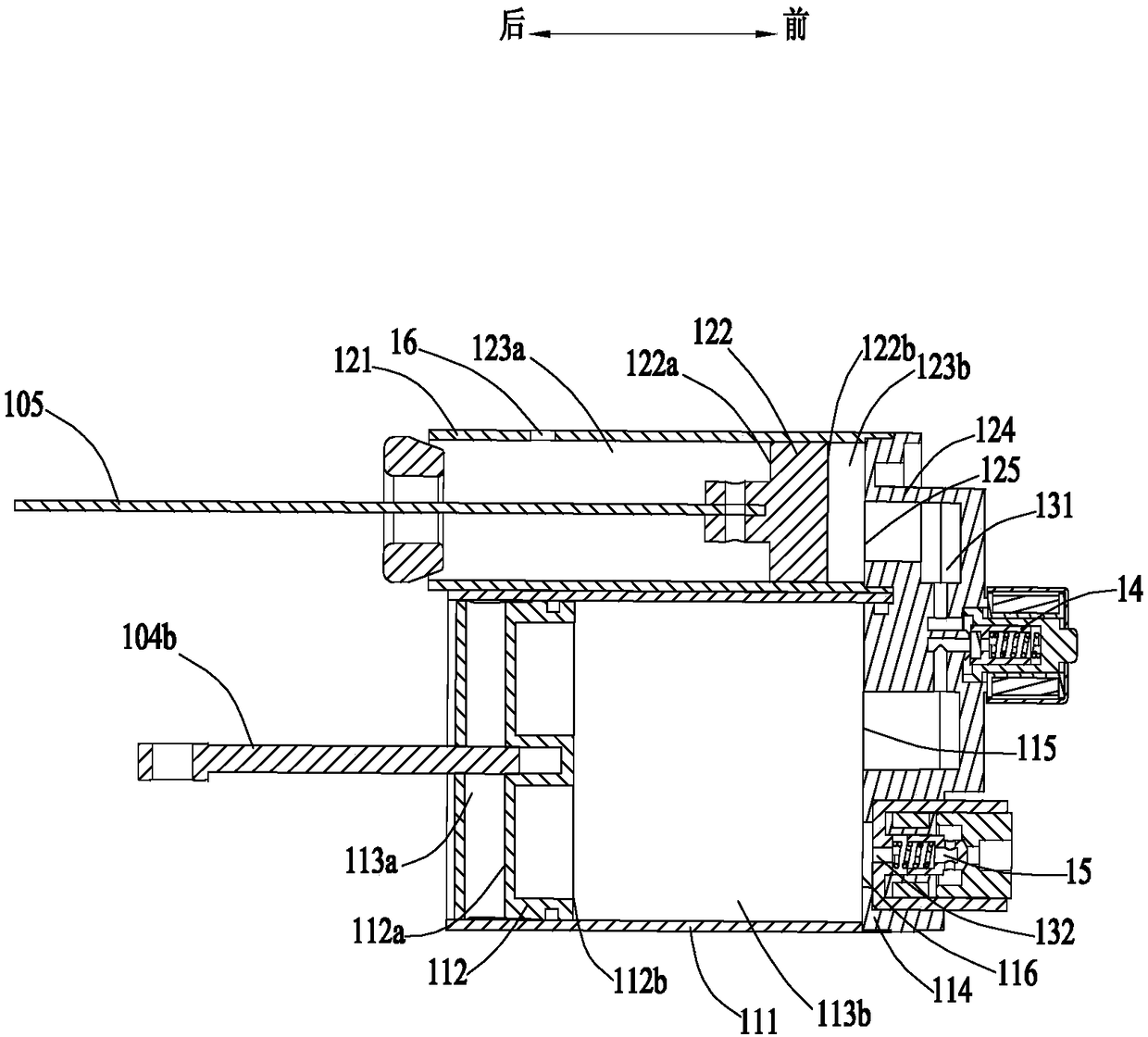

[0023] figure 1 The illustrated nail gun 100 is used to generate an impact force on a nail so that the impact nail is driven into a workpiece.

[0024] Such as figure 1 and figure 2 As shown, the nail gun 100 includes: a housing 101, a prime mover 102, an energy source 103, a driving device 104, an impact device 10, a striker 105, a locking device 106 and a nail box 107, wherein the impact device 10 includes: a first cylinder 11 And the second cylinder 12, the nail box 107 is used to accommodate nails.

[0025] The casing 101 is used to accommodate the prime mover 102 , the driving device 104 , the impact device 10 , etc., and the outside of the casing 101 is connected to a nail box 107 . Specifically, the housing 101 is formed with a handle portion 101a, a first accommodating portion 101b and a second accommodating portion 101c, wherein the first accommodating portion 101b is used for accommodating the impact device 10, and the second accommodating portion 101c is used fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com