Vibration sand discharging device for 3D printing and vibration sand spreading debugging method thereof

A 3D printing and sand laying technology, which is applied to casting molding equipment, casting molds, cores, etc., can solve the problems of increasing product rejection rate, different sanding amount, and insufficient sanding amount, so as to avoid sand leakage and control flexibly Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

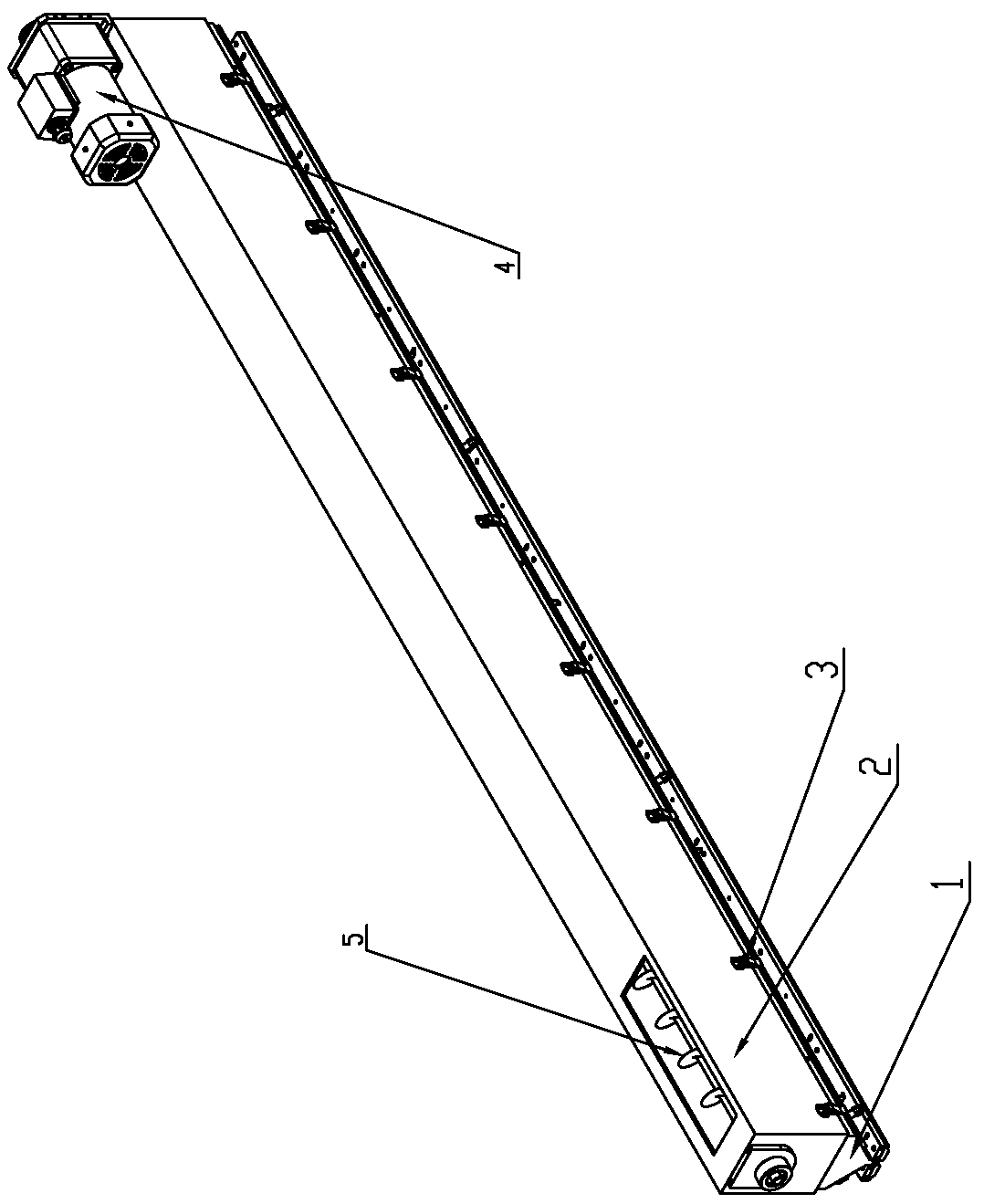

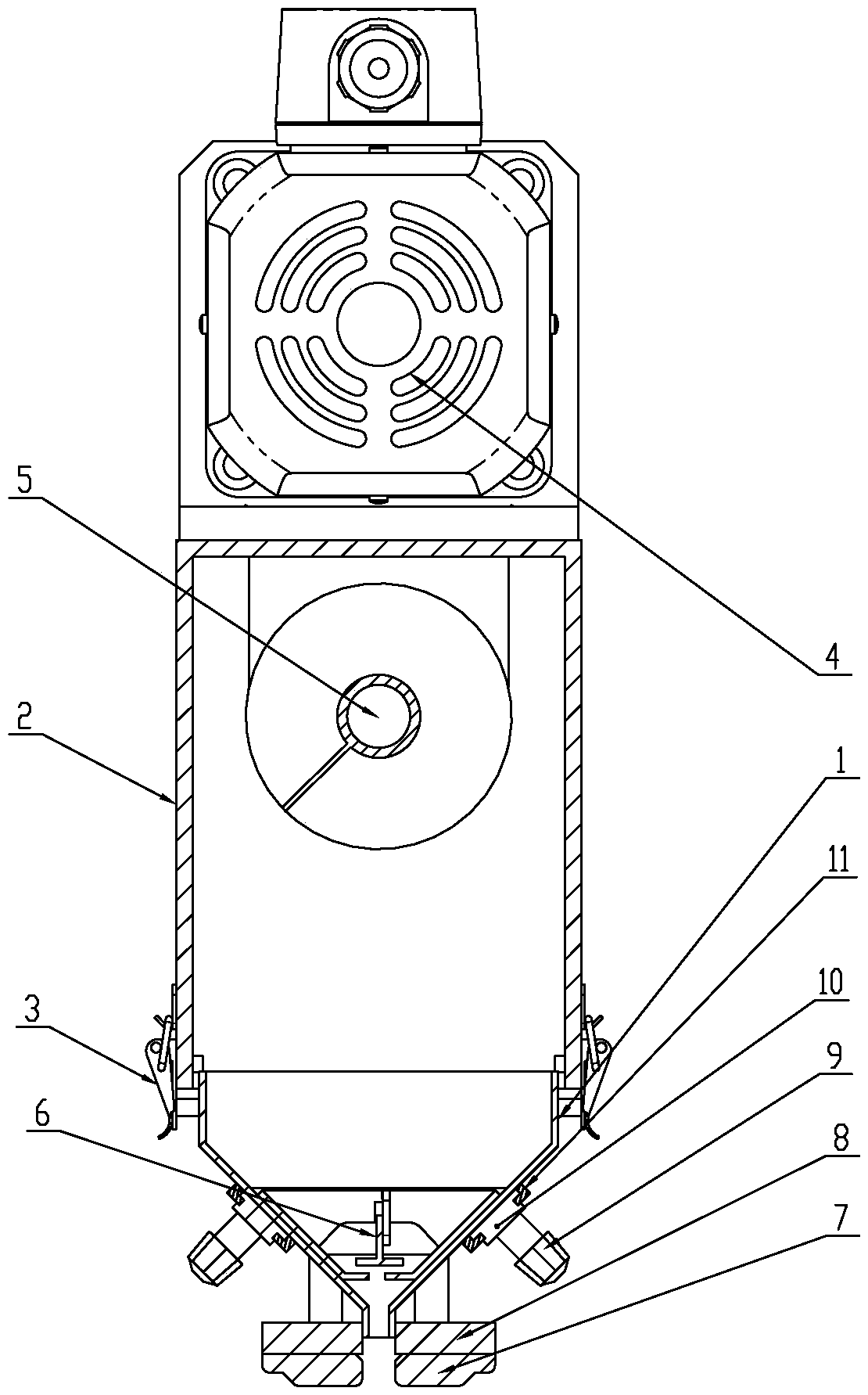

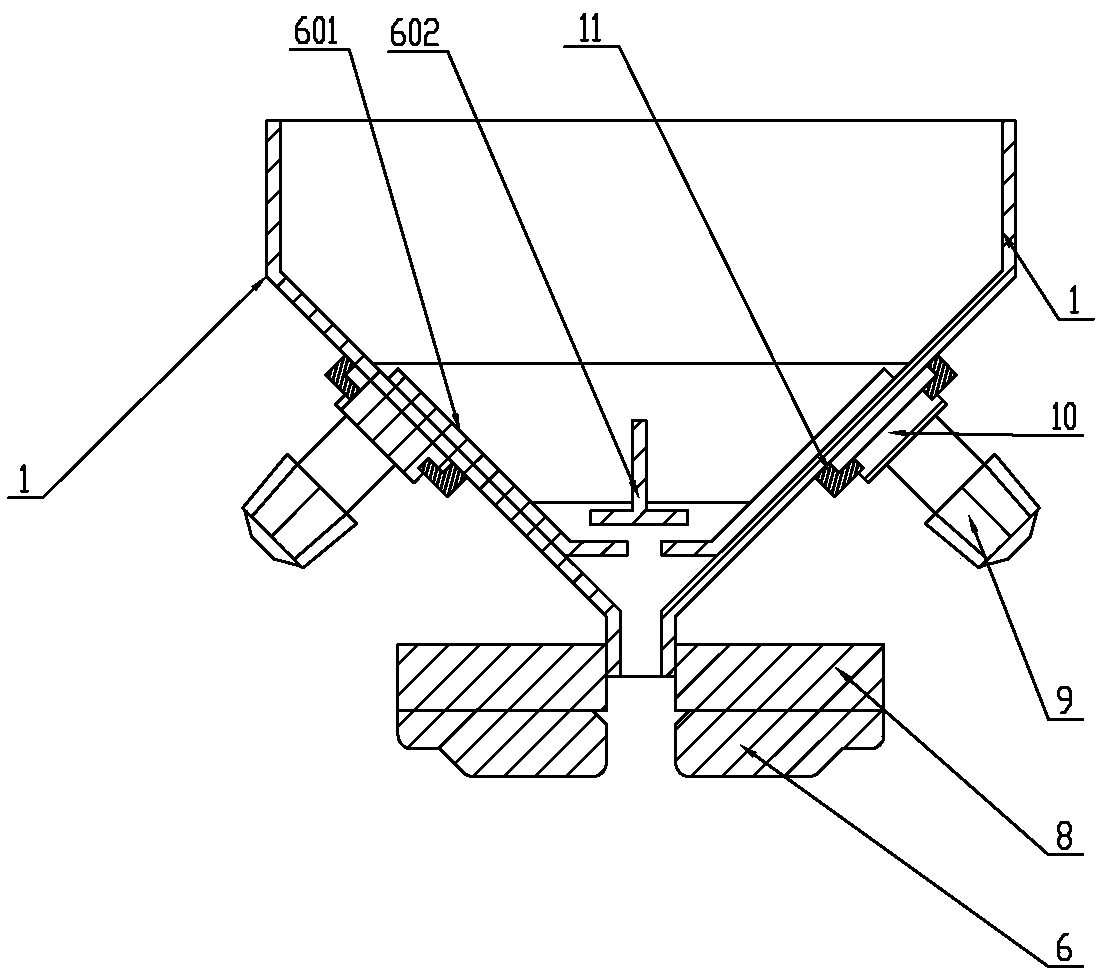

[0031] Such as figure 1 — Image 6 Shown is the vibrating sand lowering device for 3D printing of the present invention, which includes a sand bucket 1, a sand bin 2 is arranged above the sand bin 1, a spiral agitator 5 is arranged inside the sand bin 2, and an agitator motor is arranged at the top end of the sand bin 2 4. The other end of the top of the sand bin 2 is provided with a sand supply port, and the bottom of the sand bucket 1 is provided with a sand outlet with a fixed width along the length direction. The sand bucket 1 above the mouth is provided with a self-stopping sand device 6, and the two outer walls of the sand bucket 1 along the length direction are respectively symmetrically provided with slide rails 11, and several slide blocks 10 are respectively arranged on the slide rails 11. 10 is connected with a vibration cylinder 9, and the bottom of the sand outlet is connected with a sand scraper 7 through a sand scraper bracket 8 fixed on the outer wall of the s...

Embodiment 2

[0040] This embodiment is a debugging method for vibrating sand laying using the vibrating sand lowering device for the printer of the above embodiment, including the following steps:

[0041] 1) Determine the angle of repose α of the sanding powder;

[0042] 2) Disassemble the sand bucket 1 from the bottom of the sand bin 2 to expose the T-shaped sand tank 601 and the internal adjustment plate 602, adjust the height of the adjustment plate 602 in the T-shaped sand tank 601, so that the adjustment plate 602 and the T-shaped sand tank The blanking accumulation angle formed by the bending part of 601 is the same as the angle of repose α in step 1), and the adjusting plate 602 is fixed in the T-shaped sand tank 601;

[0043] 1) Determine the angle of repose of the sand powder material and the width d of the sand falling joint;

[0044] 2) Disassemble the sand bucket 1 from the bottom of the sand bin 2 to open the internal structure. First, adjust the installation height of the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com