Mounting method of metal mesh surface of umbrella antenna

An umbrella-shaped antenna and an installation method technology, which is applied in the field of installation of the umbrella-shaped antenna metal mesh surface, can solve problems such as uneven tension of the mesh surface, large differences in the shape of the mesh surface of sectors, and non-existing tension of the mesh surface, etc., to solve the accumulation of errors The effect of the phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

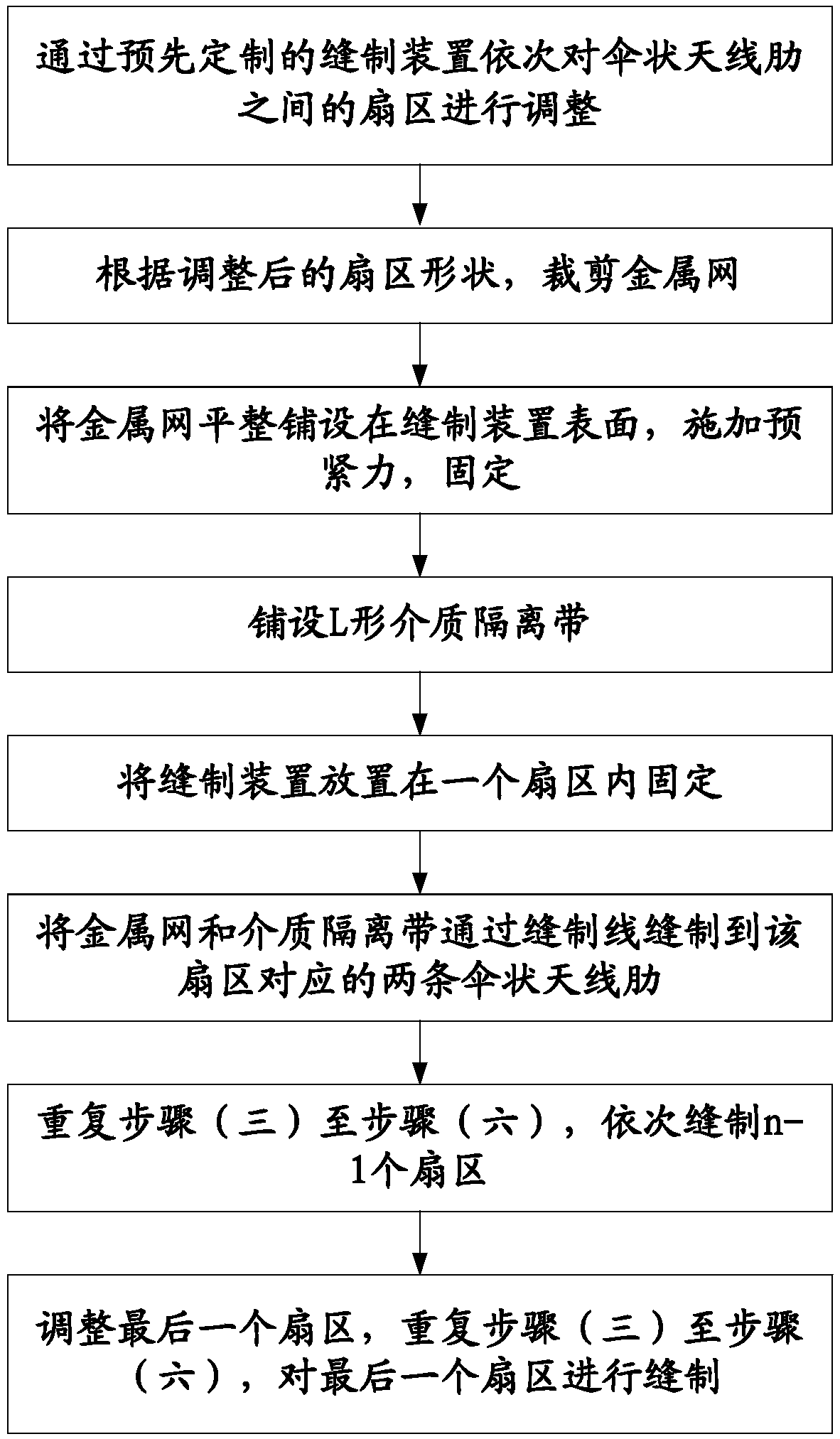

[0034] Such as figure 1 The flow chart of the installation of the metal mesh surface of the umbrella antenna is shown. It can be seen from the figure that an installation method of the metal mesh surface of the umbrella antenna includes the following steps:

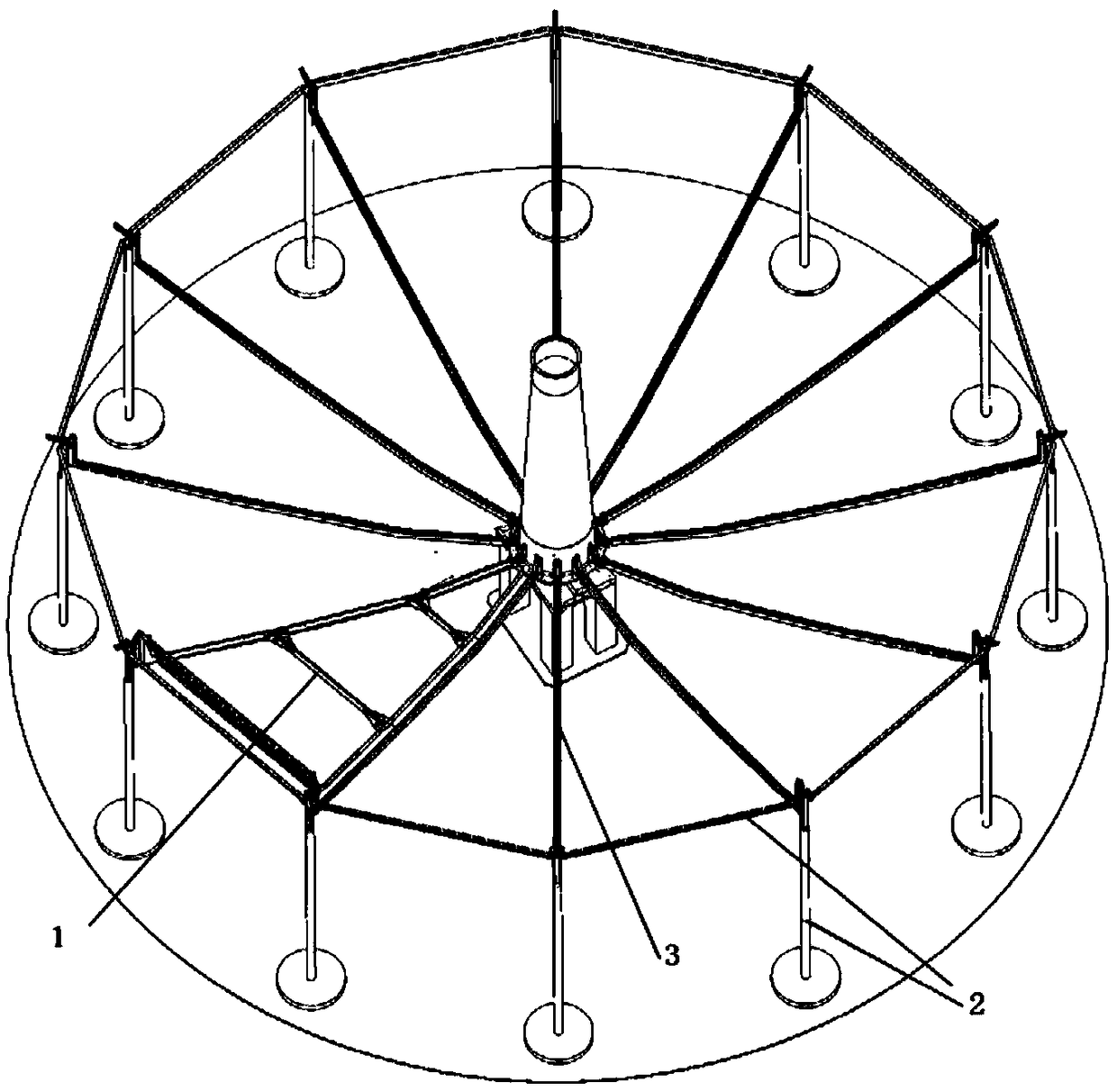

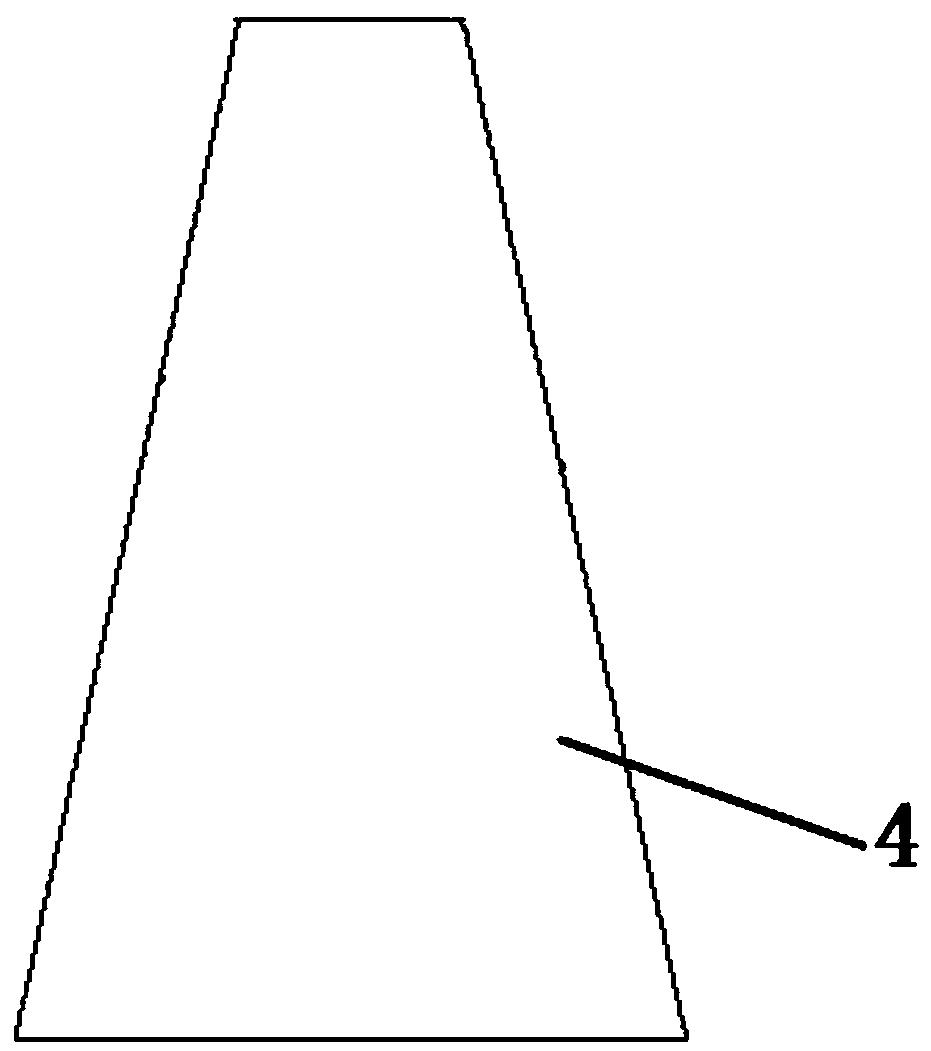

[0035] Step (1), arrange n umbrella-shaped antenna ribs 3 outwardly with the same center; divide the umbrella-shaped antenna into n sectors, such as figure 2 As shown; the sector between the umbrella-shaped antenna ribs 3 is adjusted sequentially with a pre-customized sewing device 1 with high shape precision. The sewing device 1 is an arc-shaped fan-shaped bracket structure, and the sewing device 1 is made of aluminum Material. The adjustment method of the sewing device 1 to the umbrella-shaped antenna rib 3 is as follows: the sewing device 1 is placed in the sector between the two umbr...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap