Sand abradability test experimental device and calibration experiment method of sand abrasion coefficient

A technology for testing experiments and wear coefficients, which is applied in the field of shield tunneling engineering simulation testing experiments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

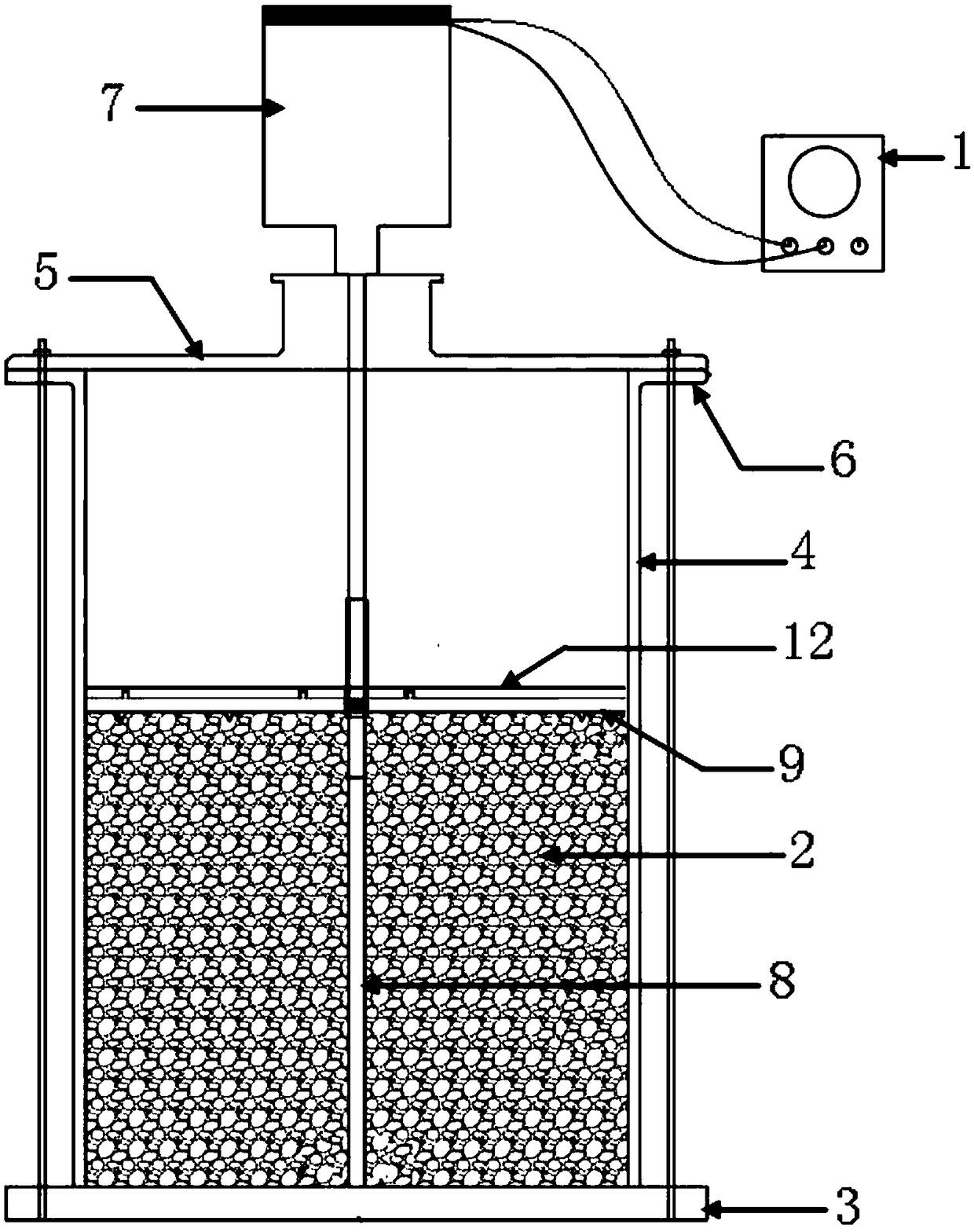

[0035] Such as figure 1 As shown, Embodiment 1 of the present invention provides an experimental device for testing the abrasiveness of sand and soil. The device includes a soil bearing cylinder, a driving mechanism, an abrasion mechanism, a loading mechanism, and a servo control device 1. The soil bearing cylinder is used for Containing sand and soil 2, the driving mechanism is arranged above the soil bearing cylinder, and is used to drive the abrasive mechanism to rotate relative to the sand and soil in the soil bearing cylinder; the loading mechanism is used for The abrasive mechanism provides an abrasive loading force so that when the abrasive mechanism and the sand rotate relative to each other, the sand will erode the abrasive mechanism; the servo control device is electrically connected to the drive mechanism and is used to control the drive mechanism. mechanism provides different rotational speeds for the abrasive mechanism.

[0036] Put sand 2 into the soil bearing c...

Embodiment 2

[0052] Embodiment 2 of the present invention provides an experimental method for calibrating the wear coefficient of sand and soil, the method comprising the following steps:

[0053] Use the sand and soil abrasive test experimental device to carry out the sand and soil abrasive test experiment;

[0054] Wherein, the servo motor 7 is controlled by the servo control device 1 to change the rotating speed of the rotating disk 9, and the normal loading force of the rotating disk 9 is adjusted by replacing the weight disk 12 with different weights. Multiple sets of wear amount data within a certain period of time, draw the characteristic curve of the wear amount of the tapered nail with the rotation speed of the rotating disc and the normal loading force on the rotating disc;

[0055] Utilize discrete element simulation software to simulate the abrasiveness test experiment of sandy soil;

[0056] Wherein, by adjusting the wear coefficient in the discrete element simulation softwar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com