Air compressor full-automatic control system and control method thereof

An air compressor and control system technology, applied in pump control, machine/engine, mechanical equipment, etc., can solve problems such as high air pressure and difficulty in starting the engine, so as to prolong the use efficiency and life, avoid blindness, and adjust the pressure process smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

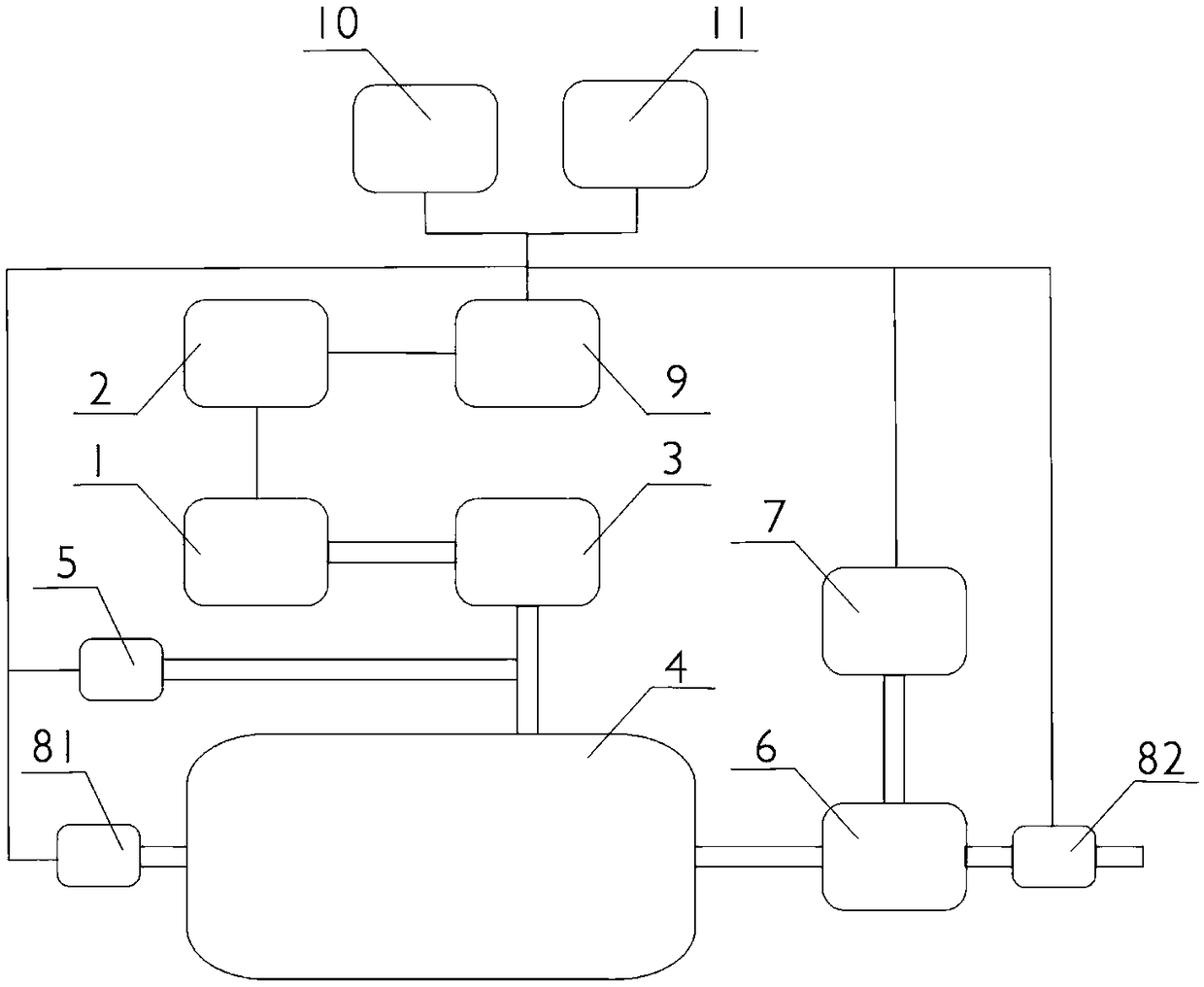

[0029] Such as figure 1 As shown, a fully automatic control system for an air compressor includes an engine 1, a relay 2, an air pump 3, an air storage tank 4, an unloading valve 5, a pressure regulating valve 6, a pressure regulating motor 7, a sensor and a controller 9, One end of the engine 1 is connected to the power supply through the relay 2, and the other end is connected to the air pump 3. The air pump 3 is connected to the air inlet of the air storage tank 4, and the connecting pipeline between the air pump 3 and the air inlet of the air storage tank 4 is provided. There is an unloading valve 5, the gas outlet of the gas storage tank 4 is connected to the pressure regulating valve 6, and the pressure regulating valve 6 is externally connected to the pressure regulating motor 7, and the gas outlets of the gas storage tank 4 and the pressure regulating valve 6 are respectively connected to the sensor a81 and the sensor b82 through the pipeline connection, the relay 2, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com