Connecting mould plate for inside corner and outside corner and with adjustable angle

A technology of yin and yang corners and templates, which is applied to the preparation of formwork/formwork components and building components on site, construction, etc., can solve problems affecting the construction period, irregular shape, material waste, etc., and improve construction efficiency and turnover rate High, easy to disassemble and adjust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

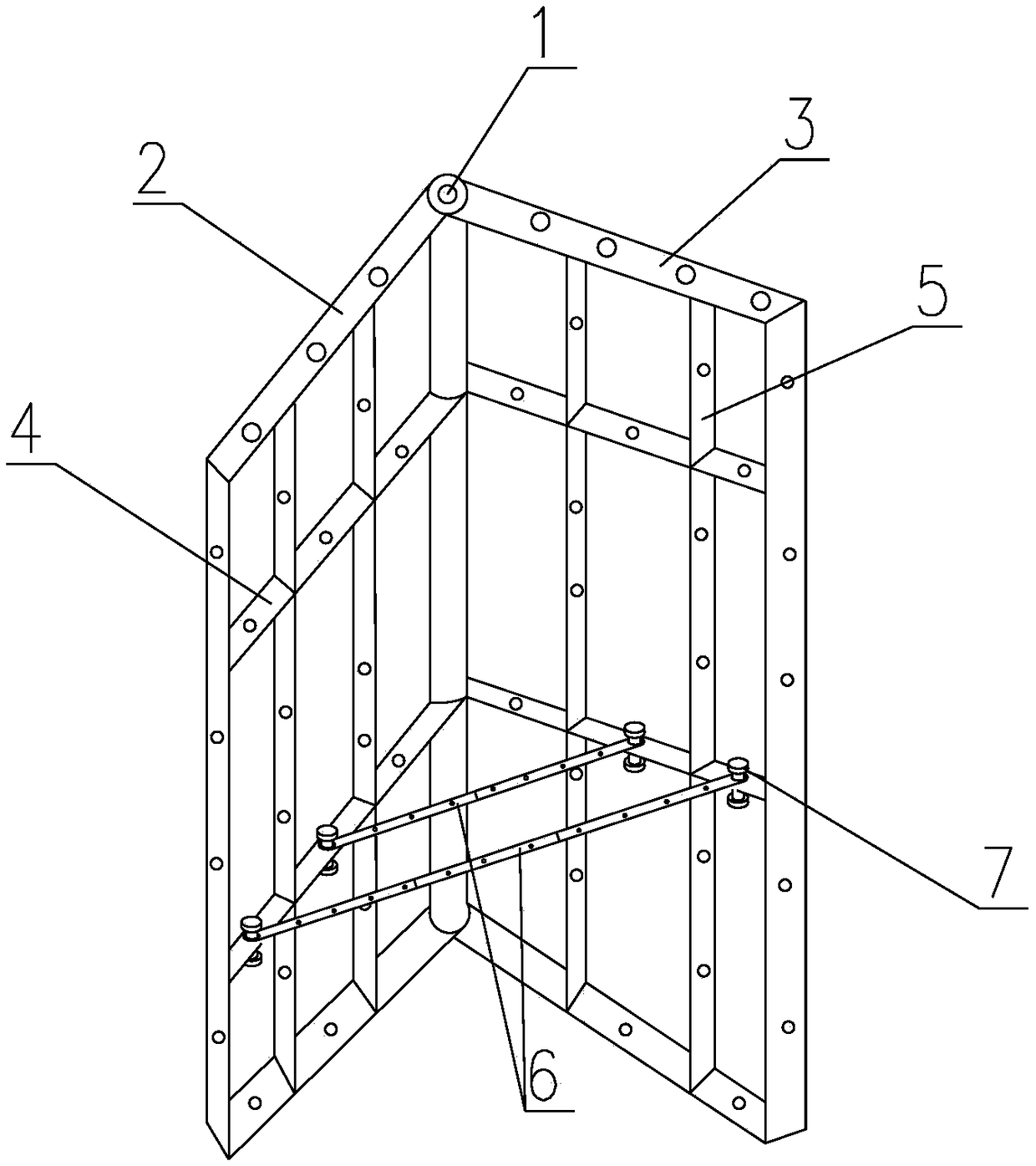

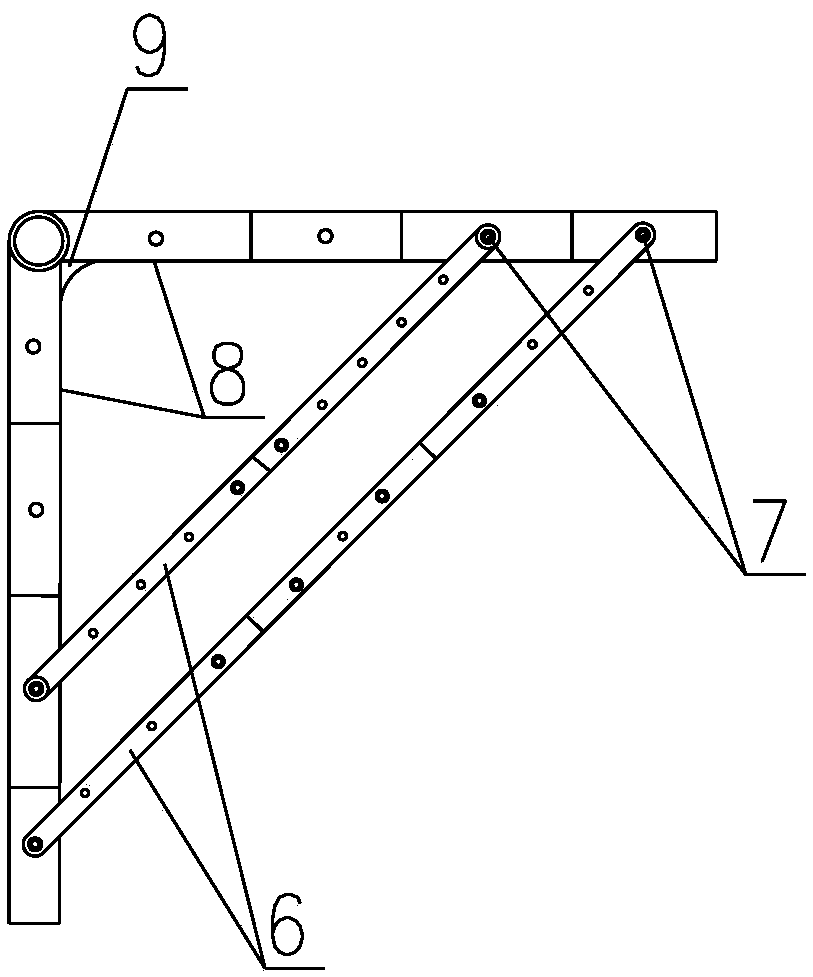

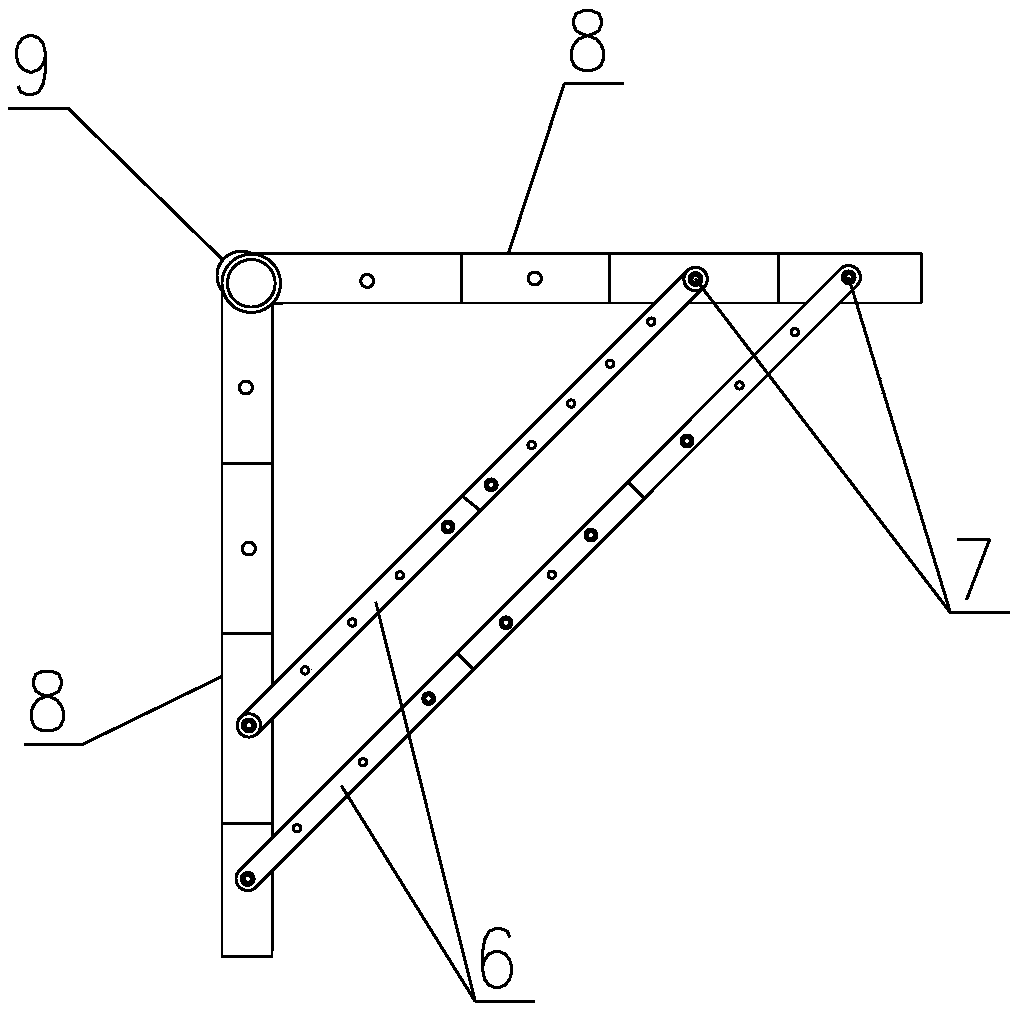

[0022] like figure 1 As shown in the present invention, an angle-adjustable dual-purpose connecting formwork for male and female angles includes a flat formwork A 2, a flat formwork B 3, an adjustable connector 6 and a shaped corner protector 9; the flat formwork A 2 and the flat formwork B 3 is composed of board surface, horizontal flute 4 with holes, and vertical flute 5 with holes. Multiple mold flute 4 with holes and vertical flute 5 with holes are intersected on one side of the board surface to form a grid structure. The other side is the working surface 8; one side of the flat template A 2 and one side of the flat template B 3 are hinged together through the connecting axis 1 to form a symmetrical structure centered on the connecting axis 1, and the working surface 8 is located at the same side; the non-working surface side of the flat form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com