Automatic acupuncture needle falling device

An acupuncture needle and needle dropping technology, applied in acupuncture, physiotherapy positioning, physiotherapy, etc., can solve problems such as increased maintenance costs, poor sustainability, stuck needles, etc., and achieves a high degree of automation, stable needle dropping, and loading large amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

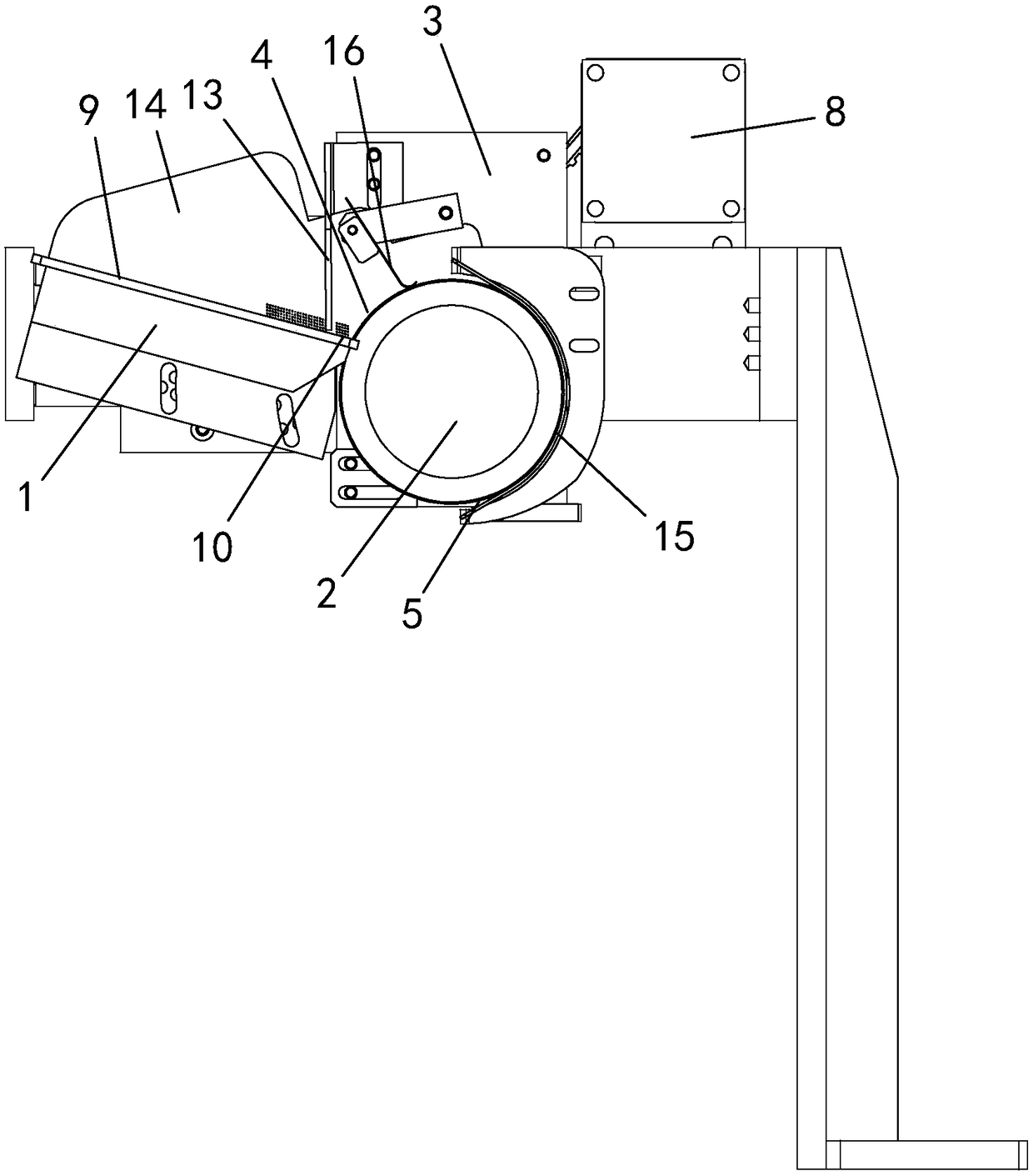

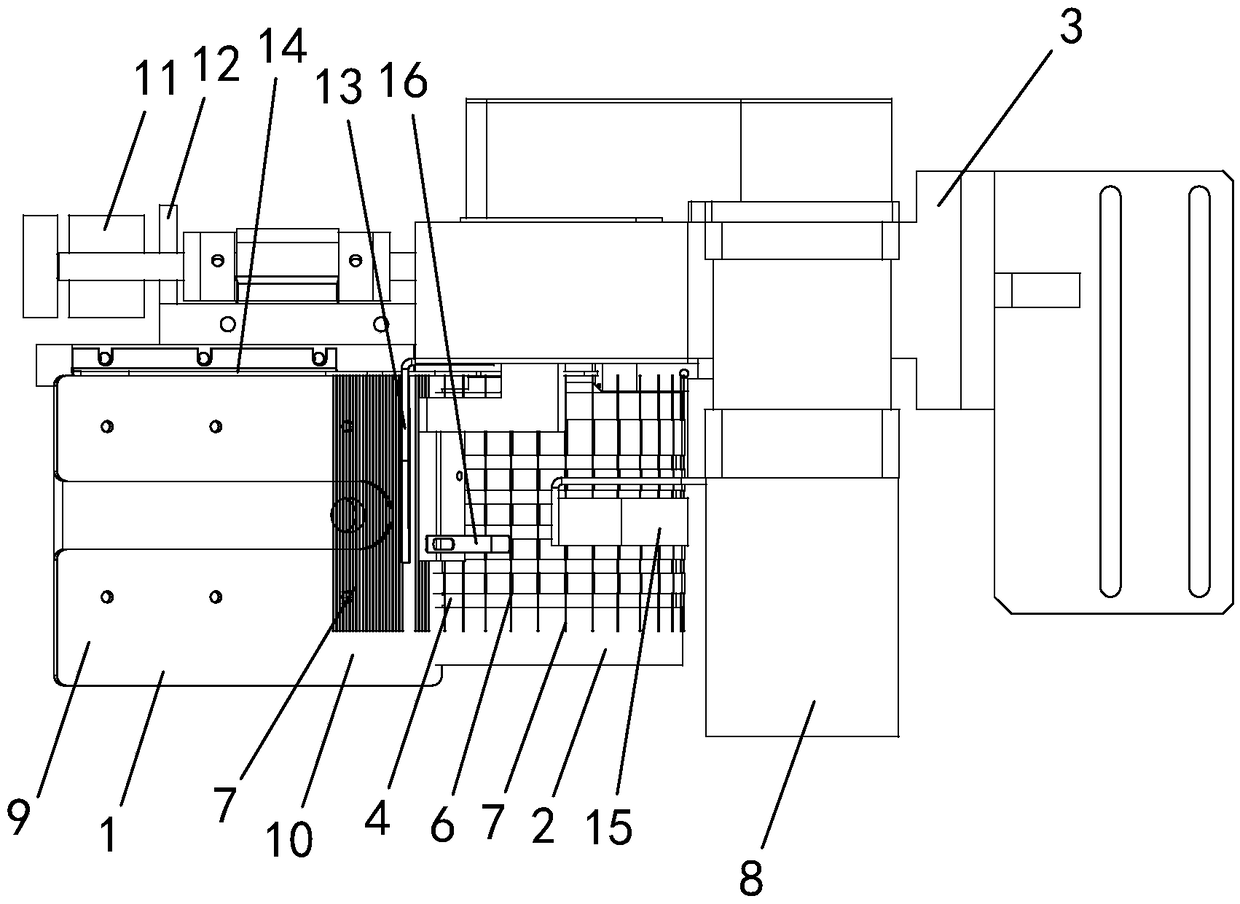

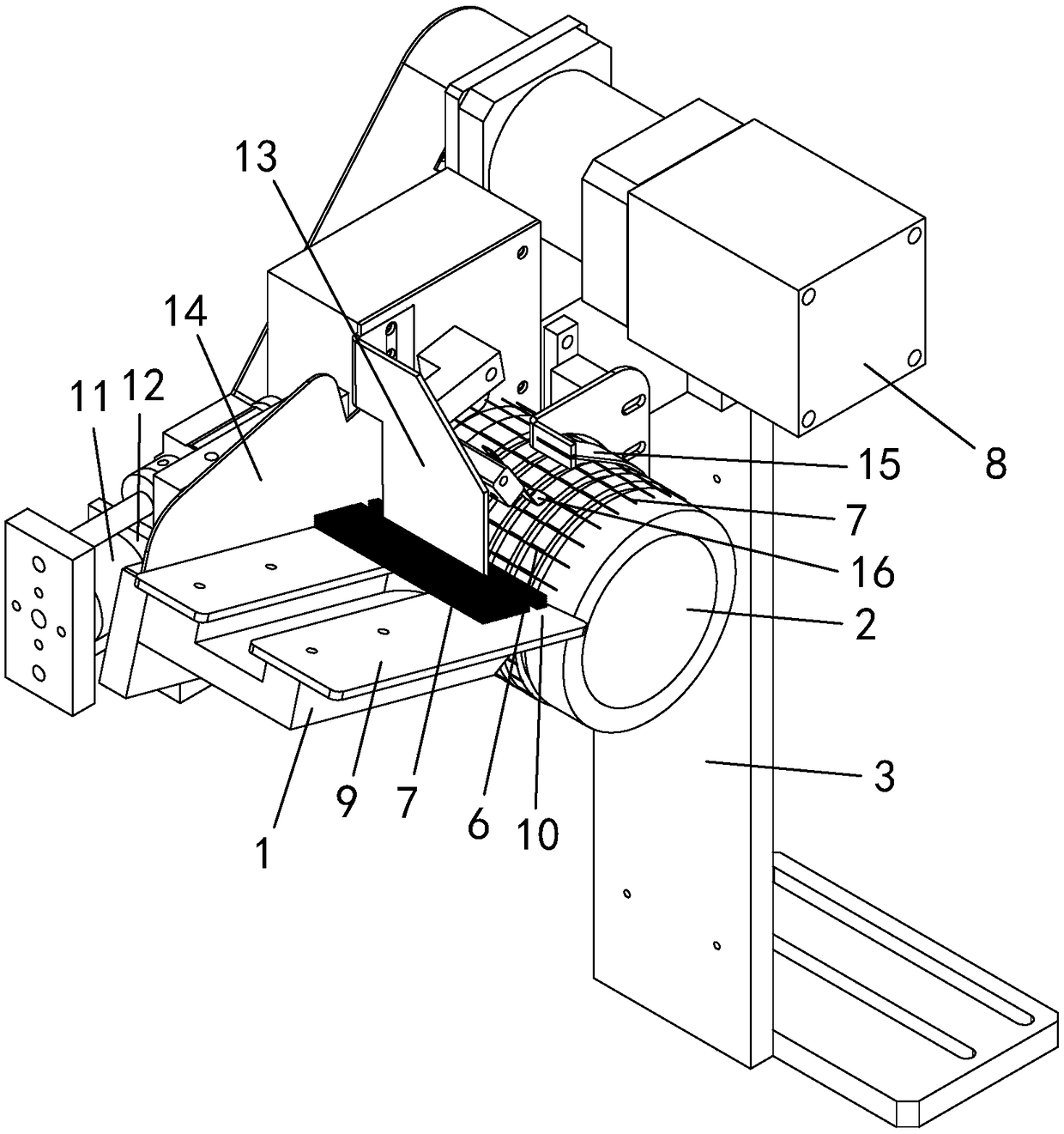

[0046] Example: see attached Figure 1~11 As shown, an acupuncture needle automatic needle drop device, including a vibrating loading table 1 and an upper needle wheel 2; wherein,

[0047] The upper needle wheel 2 has a cylindrical wheel body, which is rotated and arranged on the equipment frame 3, and its rotating shaft is horizontally arranged; the upper needle wheel 2 includes a feeding side 4 and a discharging side 5, and the feeding Side 4 is located at the front end of the upper pin wheel 2 in the direction of rotation, corresponding to the vibrating loading table 1, and the discharge side 5 is located at the rear end of the upper pin wheel 2 in the direction of rotation, and is set corresponding to the winding mechanism; the upper pin wheel A plurality of elongated minute needle grooves 6 are provided on the circumferential surface of 2, and each minute needle groove 6 is used for positioning a needle blank 7 of an acupuncture needle; each of the minute needle grooves 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com