Coal slime automatic excavator in mine flow lane

An automatic cleaning and slime technology, applied in mechanically driven excavators/dredgers, earthmoving machines/shovels, construction, etc., can solve the problems of low efficiency, many miners, and harsh working environment, and achieve high efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

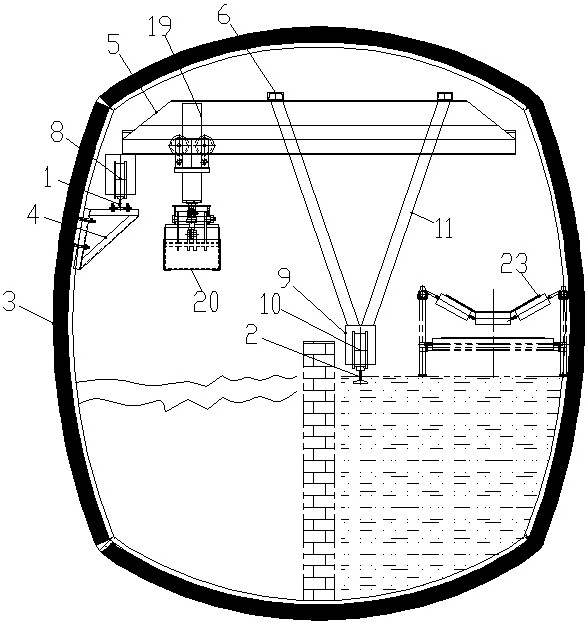

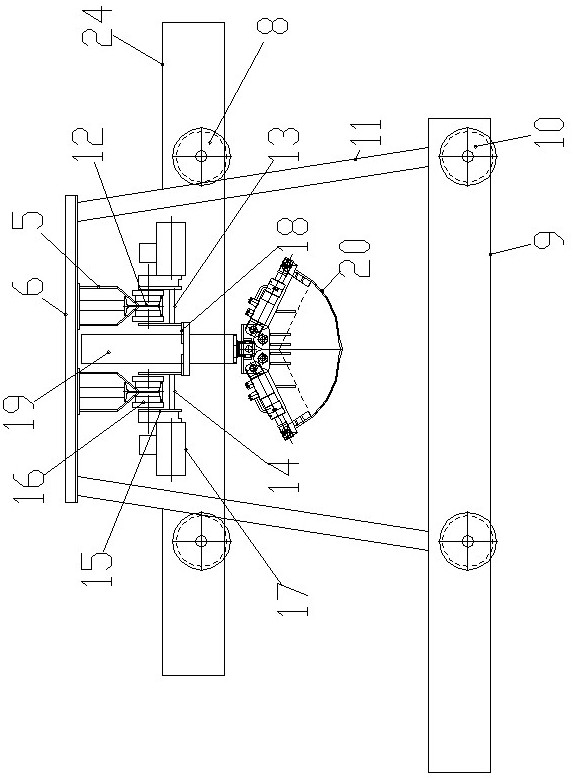

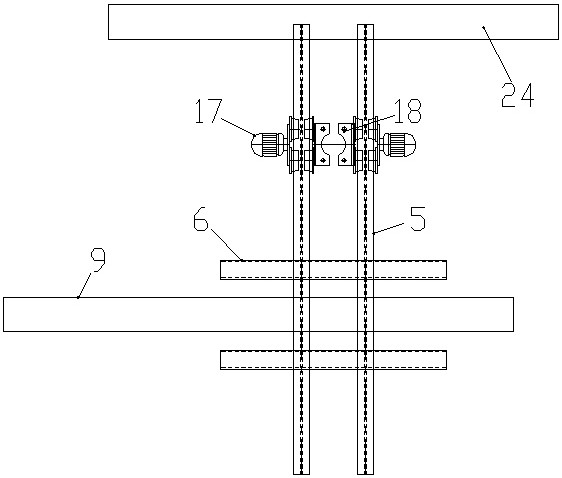

[0020] Such as Figure 1-4 As shown, the coal slime automatic dredging machine of the mine running water lane of the present invention comprises an upper guide rail 1, a lower guide rail 2 and a coal slime dredging device, and the length direction of the upper guide rail 1 and the lower guide rail 2 is arranged along the length direction of the roadway 3, The upper guide rail 1 is fixed on the upper part of the left side wall of the roadway 3, and the lower guide rail 2 is fixed on the ground on the right side of the roadway 3. The coal slime dredging device includes a mobile truss and a clearing mechanism, and the mobile truss is rollingly connected to the upper guide rail 1 and the lower guide rail 2. It can move along the length direction of the roadway 3, and the excavation mechanism is rollingly connected to the mobile truss and can move along the width direction of the roadway 3.

[0021] The upper guide rail 1 and the lower guide rail 2 are I-shaped steel, and the upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com