A kind of high-performance foam lightweight soil foaming agent and preparation method thereof

A technology of foam light soil and foaming agent, which is applied in the application field of foam light soil in highway engineering, can solve the problems of wide foam size distribution, unstable foam group density, large foam settlement distance in 1h, etc., and reaches the applicable scope. Wide, reduce the water consumption of unilateral, the effect of long half-life time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

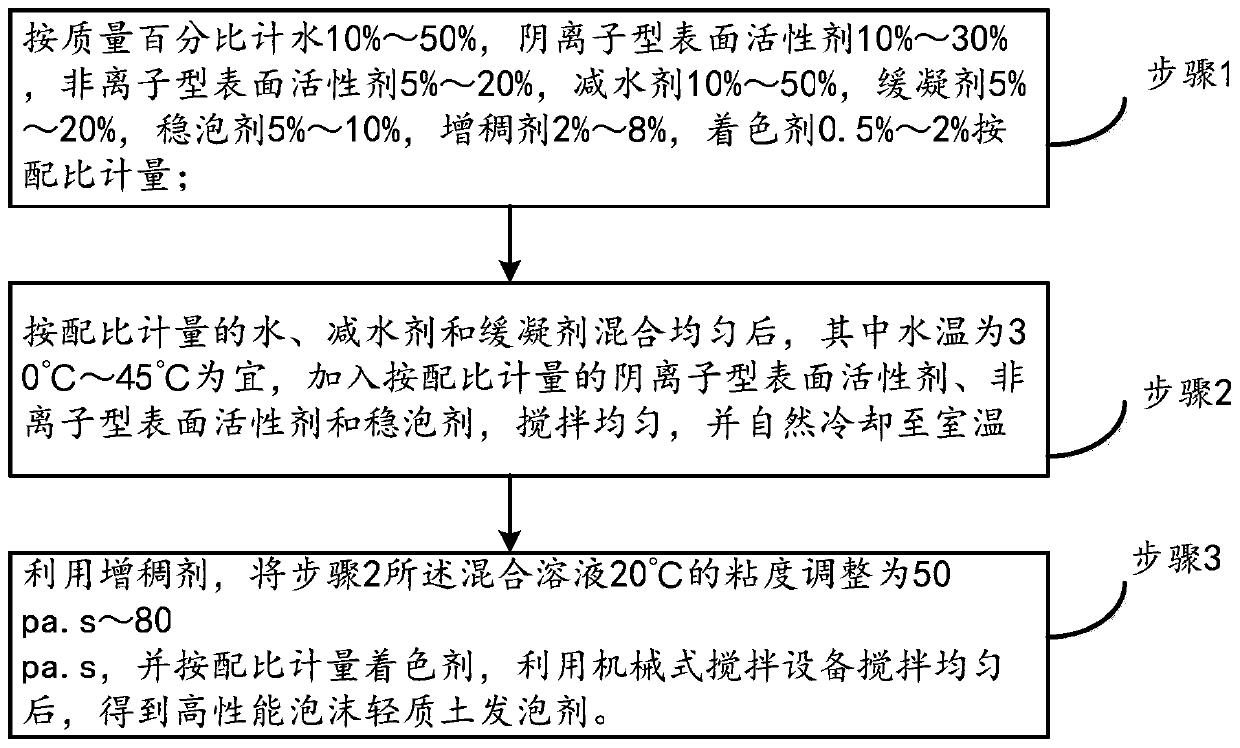

Method used

Image

Examples

Embodiment 1

[0035] (1) mix ratio

[0036] Table 1 is the mix ratio of cement slurry

[0037]

[0038] Remarks: The cement is 42.5 ordinary Portland cement, and the water is drinking water.

[0039] (2) Test method

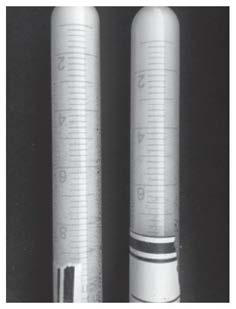

[0040] Considering the impact of cement slurry strong alkali and calcium-rich ions on foam stability, the product of the present invention carries out foam stability evaluation by improving the vibration method, and the test uses 300mL alkaline water (1: 30 cement slurry filter solution) and 10mL foaming Mix the agent, pour it into a 1000mL measuring cylinder, shake it 30 times to generate foam, record the initial foam height H, and when the foam height decreases to 1 / 2H, record the time t used, and use the foam half-life time to measure the foam stability.

[0041]A high-performance foam lightweight soil foaming agent, consisting of the following components by weight percentage: 27.5% of water, 15% of sodium lauryl sulfate, 5% of sodium lauryl sulfate, 10% of lauryl alky...

Embodiment 2

[0052] A high-performance foam lightweight soil foaming agent, composed of the following components by weight percentage: water 27.5%, sodium lauryl sulfate 20%, fatty alcohol polyoxyethylene ether (AE0-9) 10%, solid content 40% %Polycarboxylate superplasticizer 20%, sodium gluconate 15%, cocamidopropyl sulfobetaine 6%, polyacrylamide (yin) 0.5%, phthalocyanine green 1%. Measure the half-life time of product of the present invention under 15 ℃, 30 ℃, 45 ℃ and 60 ℃ environment by improved vibration method, simultaneously, form foam (foam mass density at 50kg / m2) with foaming machine foaming 3 ±3kg / m 3 ), mix the foam and the cement slurry evenly according to the volume dosage described in Table 1, and measure the performance of the foam light soil.

[0053] A preparation method of a high-performance foam lightweight soil foaming agent, comprising the following steps:

[0054] Step 1: It consists of the following components by weight percentage: 27.5% of water, 20% of sodium l...

Embodiment 3

[0064] A high-performance foam lightweight soil foaming agent, composed of the following components by weight percentage: 27.5% water, 20% secondary alkyl sodium sulfate, 10% lauryl alkyl glycoside, 40% solid content polycarboxylic acid high-efficiency Superplasticizer 15%, Sodium Gluconate 13%, Cocamidopropyl Hydroxysultaine 8%, Coconut Oil Fatty Acid Diethanolamide 5.5%, Phthalocyanine Green 1%. Measure the half-life time of product of the present invention under 15 ℃, 30 ℃, 45 ℃ and 60 ℃ environment by improved vibration method, simultaneously, form foam (foam mass density at 50kg / m2) with foaming machine foaming 3 ±3kg / m 3 ), mix the foam and the cement slurry evenly according to the volume dosage described in Table 1, and measure the performance of the foam light soil.

[0065] A preparation method of a high-performance foam lightweight soil foaming agent, comprising the following steps:

[0066] Step 1: It consists of the following components by weight percentage: 27.5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com