Pneumatic soft clamp

A pneumatic, fixture technology, used in chucks, manufacturing tools, manipulators, etc., can solve the problems of short service life of the anti-skid layer, easy scratching on the surface of the workpiece, troublesome operation, etc., to prevent scratches on the surface of the workpiece or damage to the workpiece, The effect of convenient daily maintenance and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

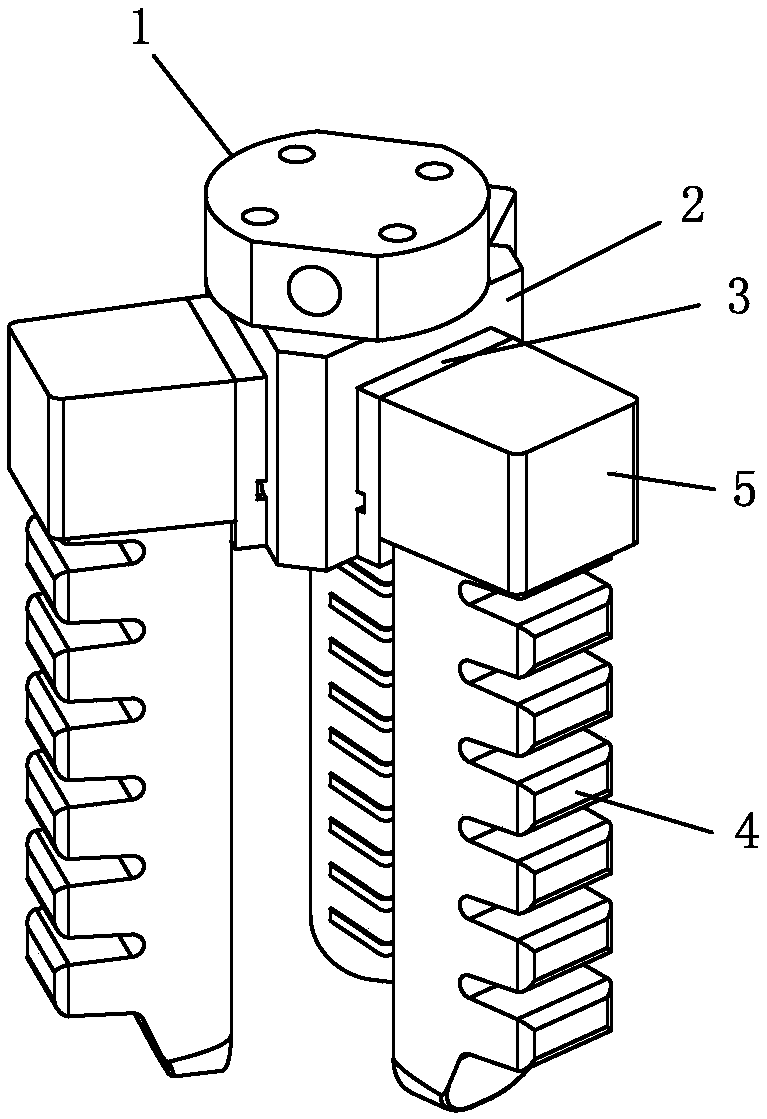

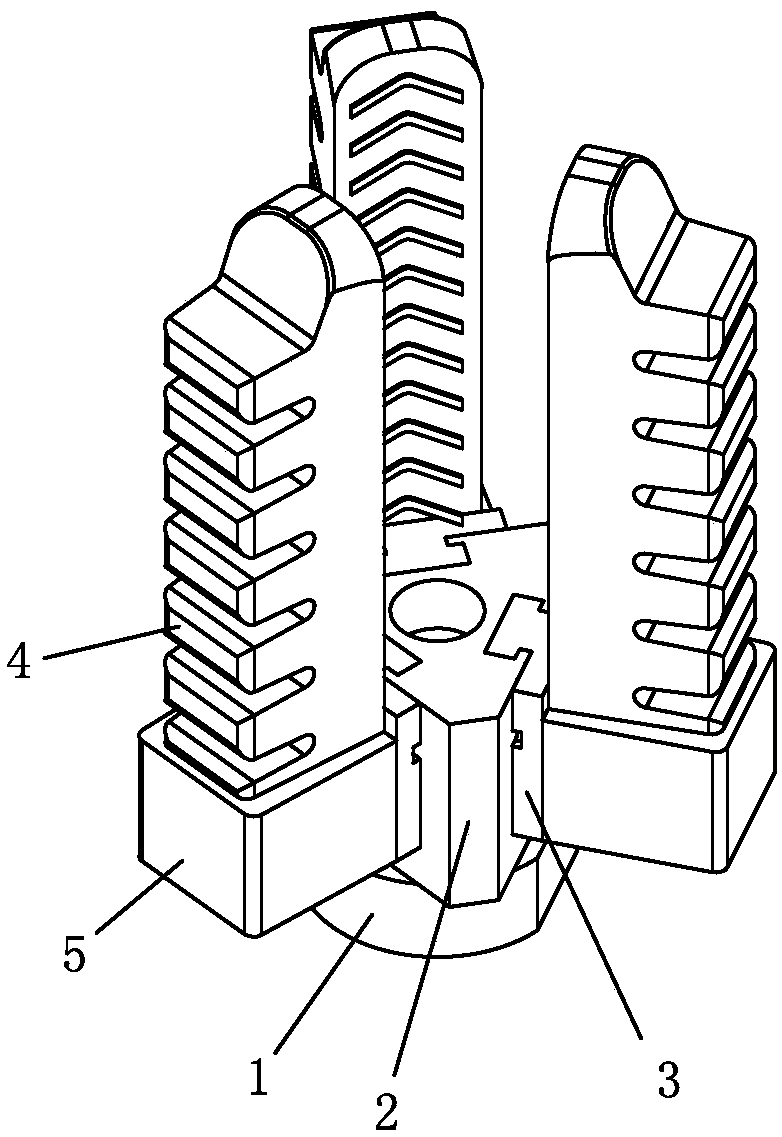

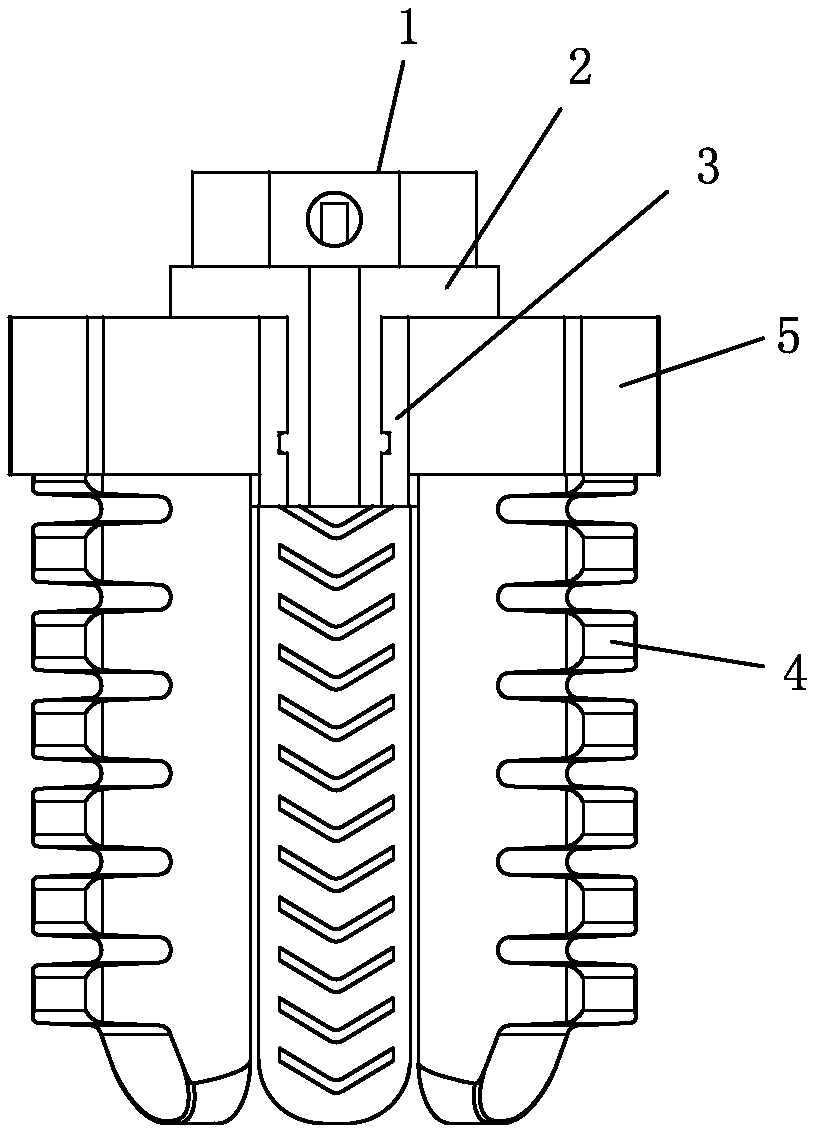

[0032] see Figure 1-Figure 10 , the pneumatic soft clamp includes a clamp base 2, and three soft jaws 4 are evenly distributed in a ring around the clamp base 2, and each soft jaw 4 is integrally formed by a soft material (rubber); The inner side of the soft jaw 4 is provided with a bendable clamping side 401, and the outer side is provided with a retractable telescopic side 402, and the clamping side 401 is opposite to the telescopic side 402; the soft jaw 4 is hollowed out with a comb-shaped air bag; In the initial or working state, the airbag is inflated, the clamping side 401 is flat or turned inward, the telescopic side 402 is stretched, the soft gripper 4 is straight or turned inward as a whole, and the gripping side 401 of two or more soft grippers 4 is in common Clamp the workpiece to achieve the effect of clamping the workpiece; in the open state, the air bag is vacuumed, the clamping side 401 is turned outward, the telescopic side 402 is contracted, and the soft jaw...

no. 2 example

[0041] see Figure 11-Figure 16 , This pneumatic soft clamp is different from the first embodiment in that: there are six soft clamping jaws 4 evenly distributed around the clamp base 2; in addition, the soft clamping jaws 4 can also be set to four or five , seven or eight, etc.

[0042] Other parts not described are the same as those of the first embodiment, and will not be described in detail here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com