Shell hardness detecting device for display screen shell processing

A technology of shell hardness and detection device, which is applied in the direction of measuring device, test material hardness, strength characteristics, etc., can solve the problems of display shell movement, lack of fixing devices, and influence of test results, etc., to achieve the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

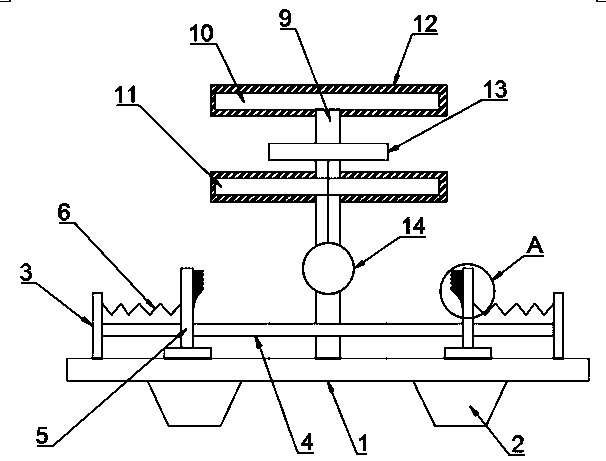

[0019] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

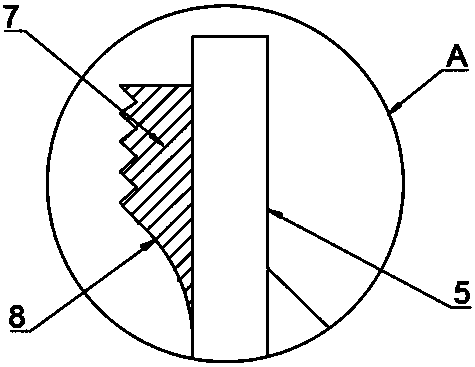

[0020] refer to Figure 1-2 , a shell hardness testing device for display screen shell processing, comprising a testing platform 1, a plurality of non-slip bases 2 are fixed on the lower side wall of the testing platform 1, the anti-skid base 2 is set to make the testing platform 1 placed more stable, and the upper side of the testing platform 1 Two support plates 3 are fixedly connected to the side wall, and a slide bar 4 is fixedly connected between the two support plates 3. The slide bar 4 is provided with a clamping mechanism, and the clamping mechanism includes two sliding sleeves arranged on the outer wall of the slide bar. The lower side walls of the two slide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com