Production system for fluorinated surfactant

A fluorosurfactant and production system technology, applied in the directions of dissolution, chemical instruments and methods, chemical/physical processes, etc., can solve the problems that solvents and solid catalysts cannot be recovered and recycled, and solve the problems that cannot be recovered and recycled. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings. It should be noted that the described specific embodiments are only intended to facilitate the understanding of the present invention, rather than limiting it in any way.

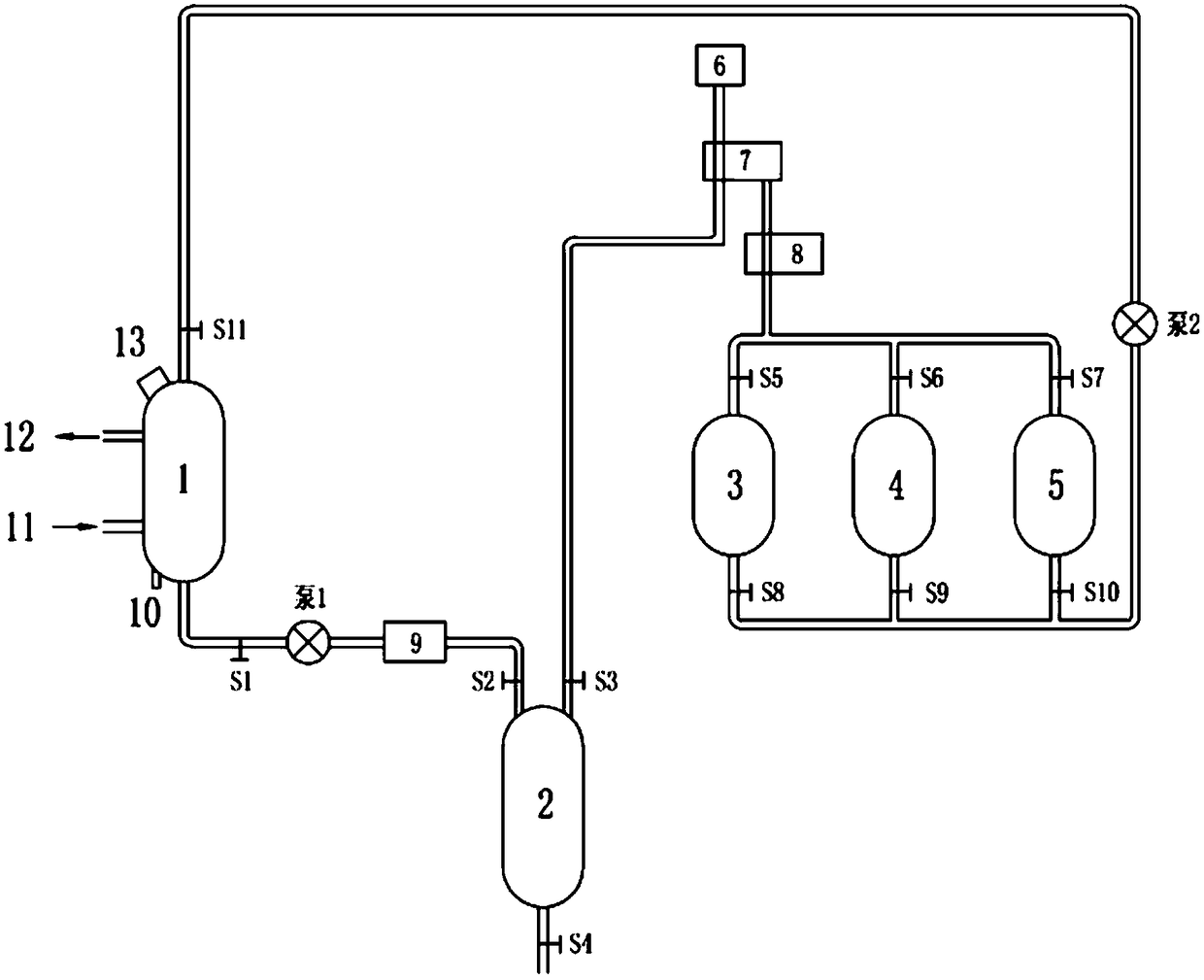

[0020] Such as figure 1 As shown, the fluorosurfactant production system of the present invention includes a reaction tank 1 , an evaporation tank 2 and solvent storage tanks 3 , 4 , and 5 . The top of the reaction tank 1 is provided with a feeding port 13 and a solvent liquid inlet, and the bottom is provided with a solvent liquid outlet. The reaction tank 1 is also provided with a heating cycle and temperature control unit 10. The heating cycle and temperature control system 10 can be controlled at ±0.1°C The reaction temperature in the reaction tank 1 is precisely controlled within the temperature range. A solvent inlet valve S11 is set at the solvent inlet at the top of the reaction tank 1, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com