Beverage production process

A production process and beverage technology, applied in the direction of food science, etc., can solve problems such as poor cooling effect and energy waste, and achieve the effects of saving cooling process water, energy consumption, and low production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

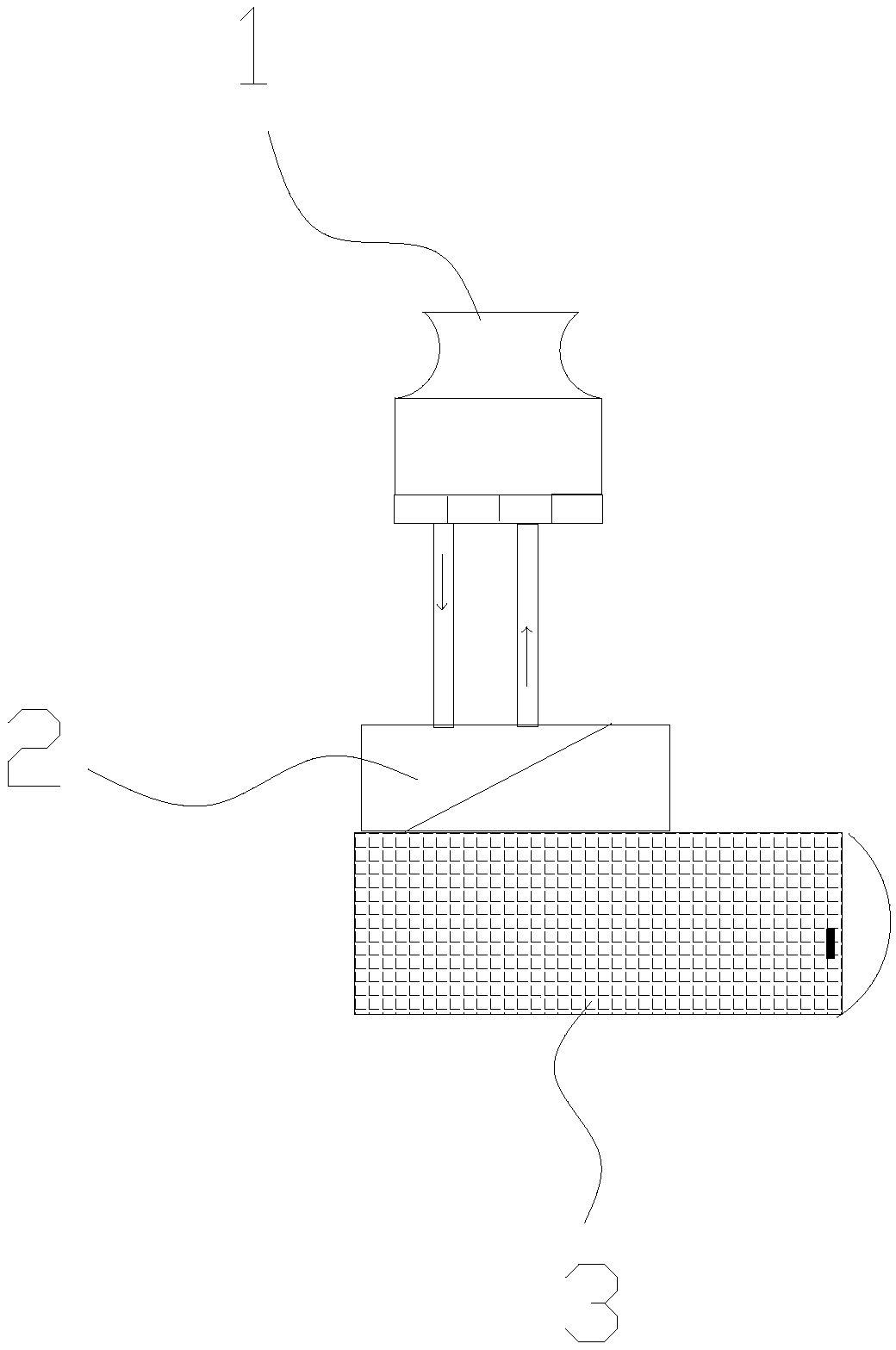

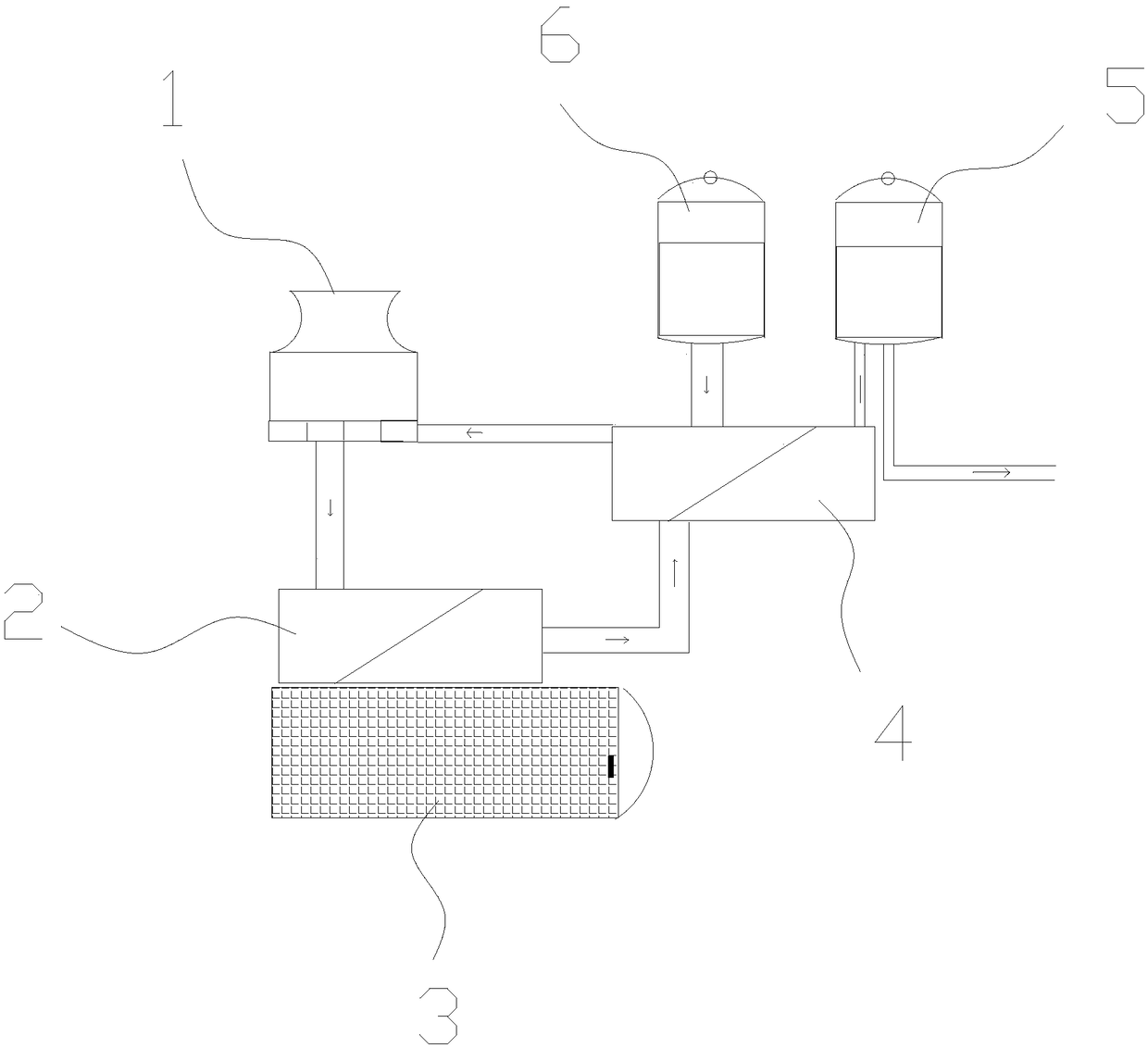

[0025] to combine figure 1 , in the existing plant beverage production process, because the beverage product needs to be cooled after the high-temperature sterilization step, the existing technology is to directly pass the circulating water with a lower temperature in the cooling tower 1 through the first heat exchanger 2 and the sterilizing pot 3 Perform heat exchange to reduce the temperature of the product in the retort 3, while the temperature of the low-temperature circulating water in the cooling tower 1 rises and returns to the cooling tower 1 again. Such repeated circulation continuously reduces the temperature of the product in the retort 3. This method not only has a bad cooling effect, but also brings great energy consumption a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com