Methodology for preparing ethanol-reduced fermented beverages

A technology of alcoholic beverages and yeast, which is applied in the fields of food, wine and fermented beverage industries, and can solve problems such as lack of volatile compounds and secondary metabolites, and lack of qualifications for international competition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Crude must, processed by removal of stems from Alexandria muscat grapes and subsequent crushing of the grapes, is stored in fermentation vessels made of stainless steel, previously sterilized by moist heat.

[0050] Depending on the yeast concentration to be obtained, several hours before inoculation of Pichia anomala, it is necessary to inoculate the liquid medium YM (3g / L yeast extract, 3g / L malt extract, soybean, 5g / L soybean peptone , 10g / L glucose) to start its cultivation to produce biomass. Just before use, the culture must be harvested by centrifugation at 5000 RPM, resuspended in sterile distilled water, and washed three times. It was then lightly wetted with a 4.5 mM solution of alginic acid, since it is a liquid culture which does not require proper activation but incubation in the presence of alginate. It was left to stand at 28°C for 20 minutes.

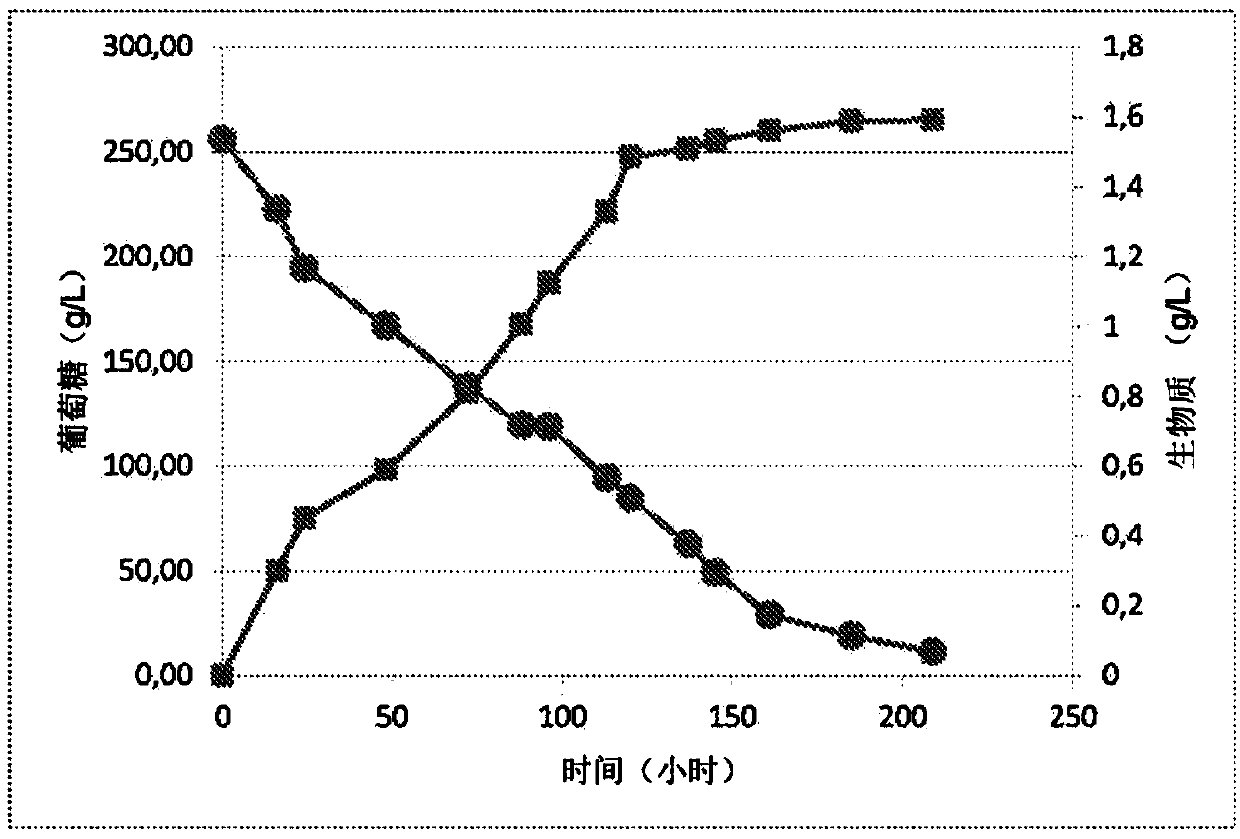

[0051] The first stage of fermentation consisted of aeration of the medium, which was increased throughout th...

Embodiment 2

[0056] Fermentation is carried out from concentrated must of red grapes. Pichia anomala was grown in YM-glycerol medium (3g / L yeast extract, 3g / L malt extract, 5g / L soybean peptone, 10g / L glucose, 5% glycerol) for 96 hours to produce biomass. Just before use, the culture must be harvested by centrifugation at 5000 RPM, resuspended in sterile distilled water, and washed three times. Subsequently, lightly wet with a 4.5 mM alginic acid solution. It was left to stand at 28°C for 20 minutes.

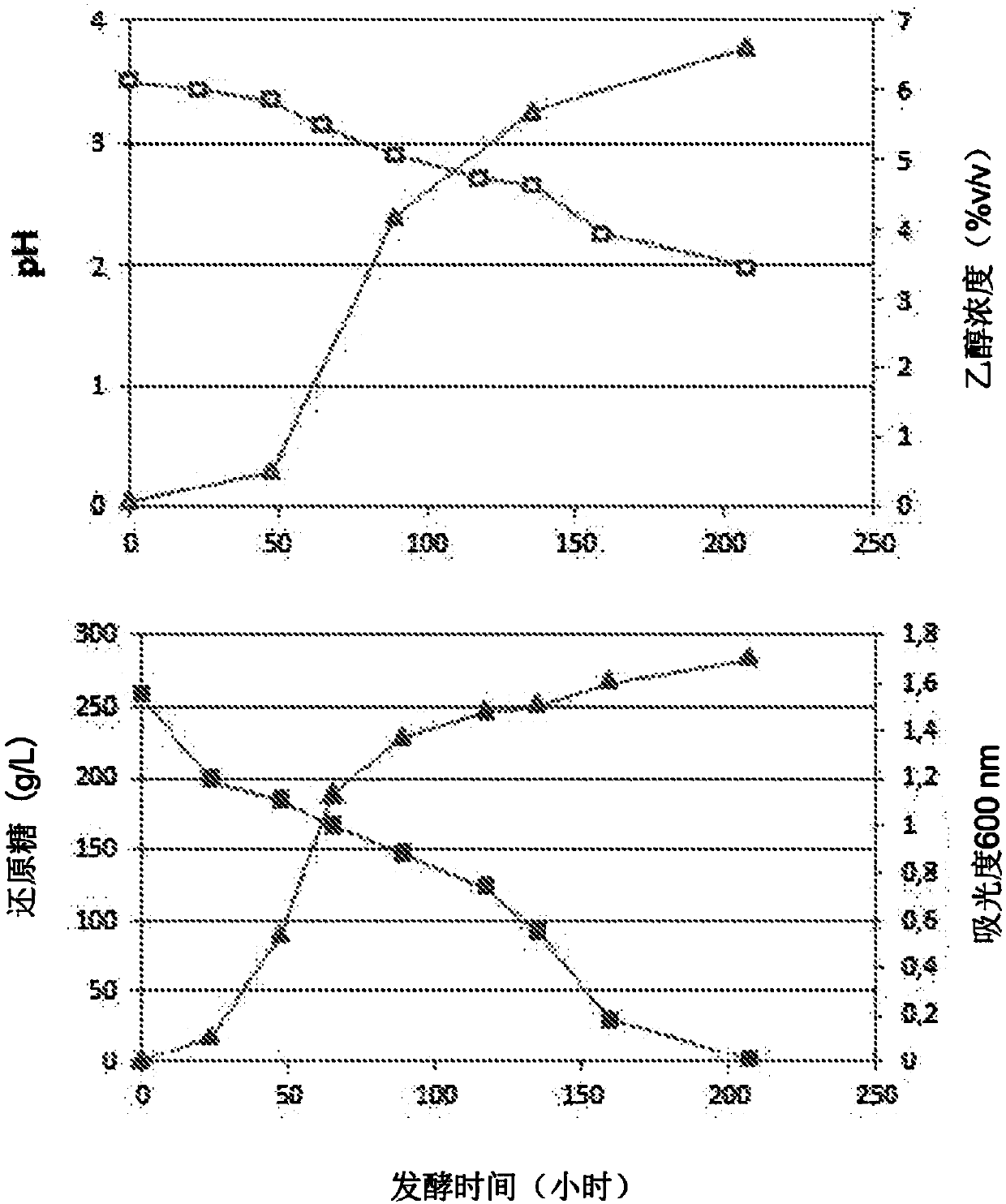

[0057] The first stage of fermentation consisted of aeration of the medium, which was increased throughout the process to maintain a constant dissolved oxygen concentration of 10 mg / L. At the beginning of the fermentation and after 72 h, the process had to be controlled every 10 h in order to quantify the concentration of sugars consumed and biomass produced ( image 3 ). Aeration was stopped when the yeast reached 32 g / l residual sugar.

[0058] Once the sugar peaks, the aeration is s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com