Negative-pressure uniform coating crossed yoke method magnetic powder detection crawling device

A technology of magnetic particle detection and crawling device, applied in the direction of injection device, liquid injection device, material magnetic variable, etc., can solve the problems of multiple detection dead spots, uneven coverage, slow speed of magnetic suspension, etc. Comprehensive, well-designed effects of tracked images

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

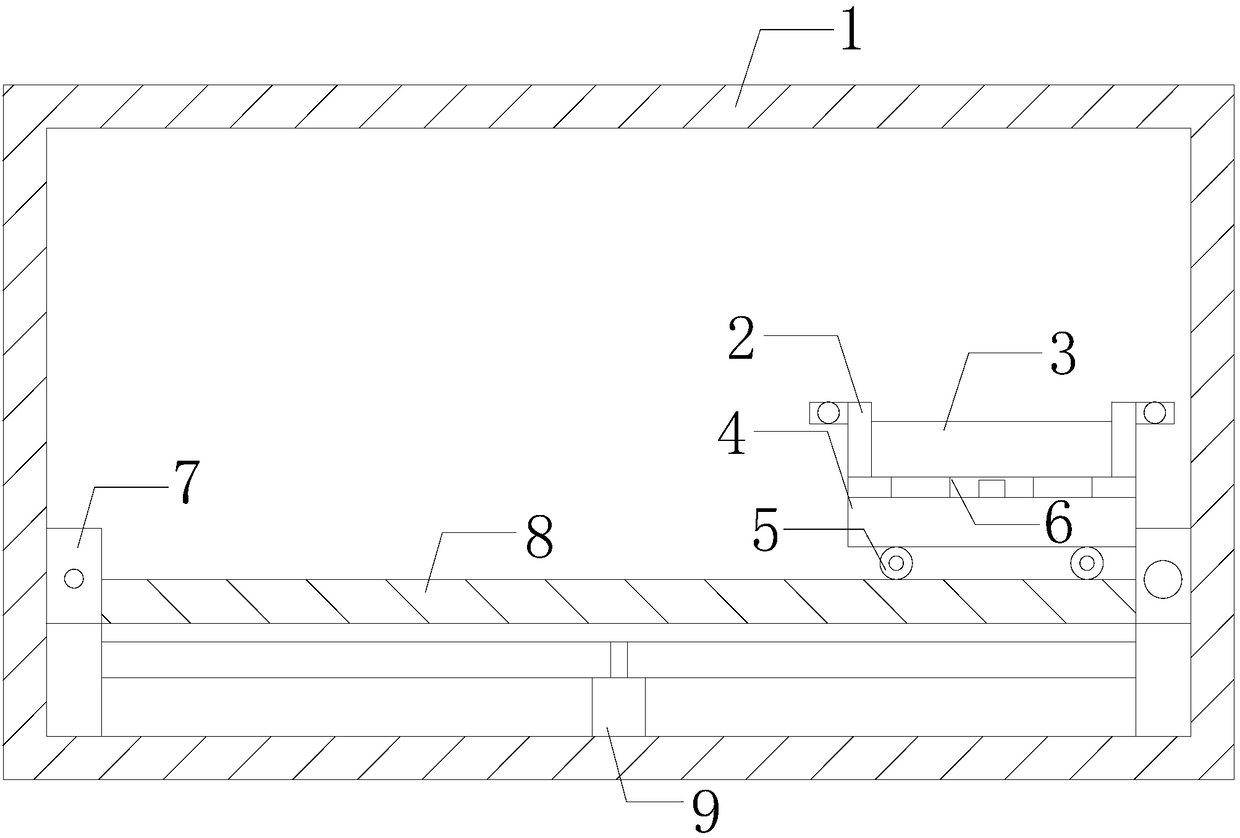

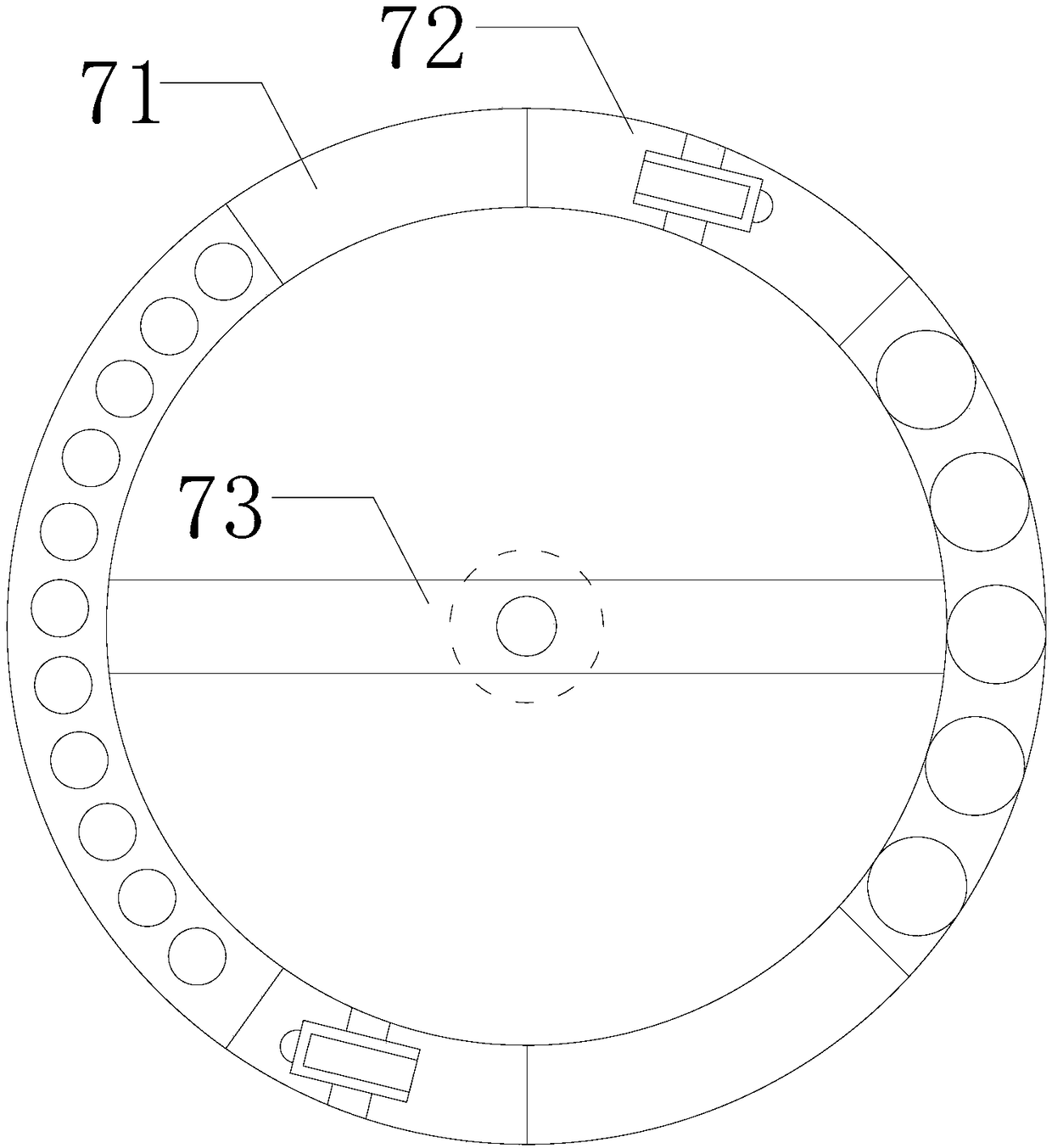

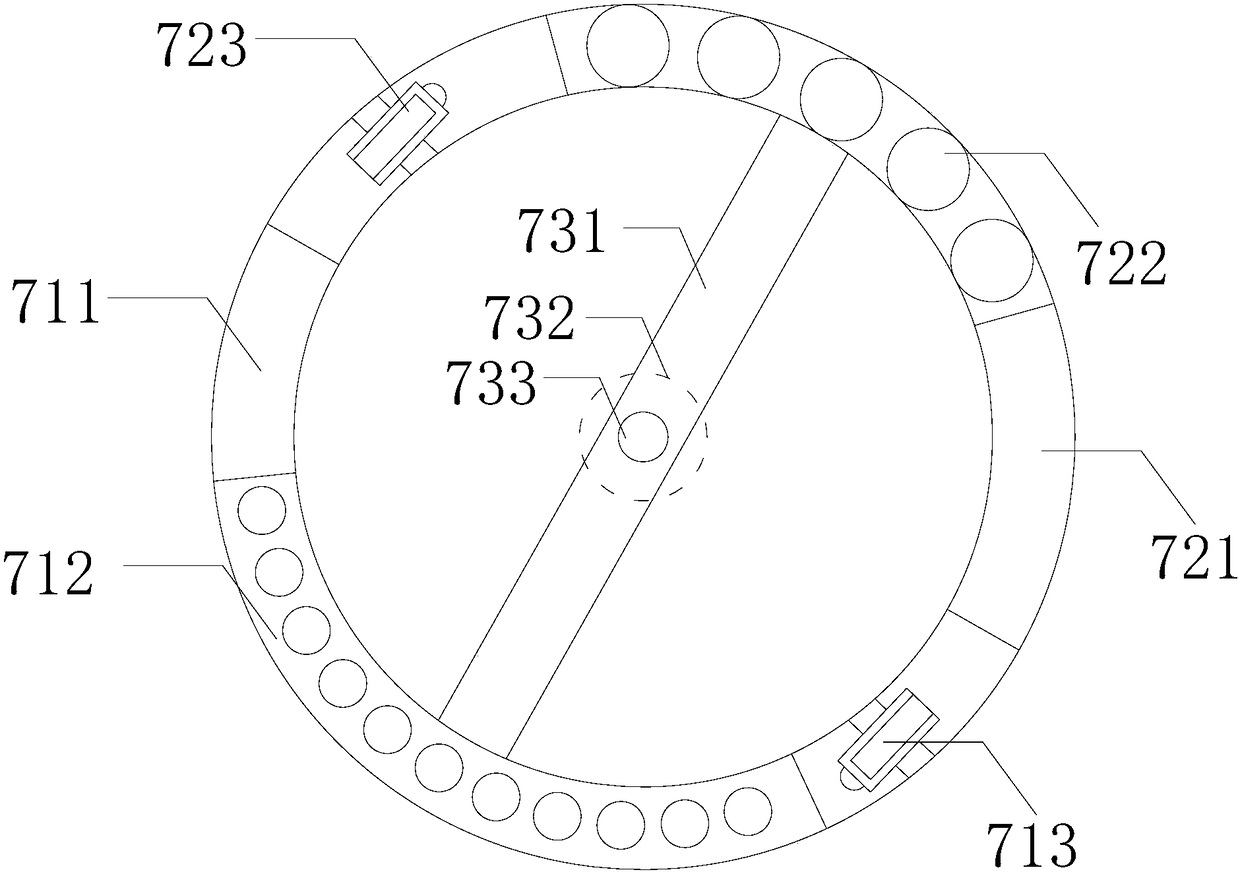

[0024] see figure 1 , the present invention provides a crawling device for cross-yoke method magnetic particle testing with negative pressure and uniform coating: its structure includes an external expansion shell 1, a supplementary light 2, a cross-yoke type magnetic particle flaw detector 3, a frame 4, and a movable wheel 5 , liquid spray pot 6, negative pressure ring 7, magnetic plate placement column 8, drive motor 9, the two ends of the negative pressure ring 7 are movably connected to the left and right ends of the outer shell 1, and the magnetic plate placement column 8 is installed In the middle of the negative pressure ring 7 and do not intersect, the drive motor 9 is located below the magnetic plate placement column 8 and is mechanicall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com