Vehicle-mounted clamping conveying device

A technology of clamping and conveying and jaws, which is applied in the field of clamping and conveying devices for vehicle accessories, can solve the problems of complex assembly and disassembly of workpieces, achieve good clamping effect, simple operation, and avoid loosening or even detachment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Further detailed explanation through specific implementation mode below:

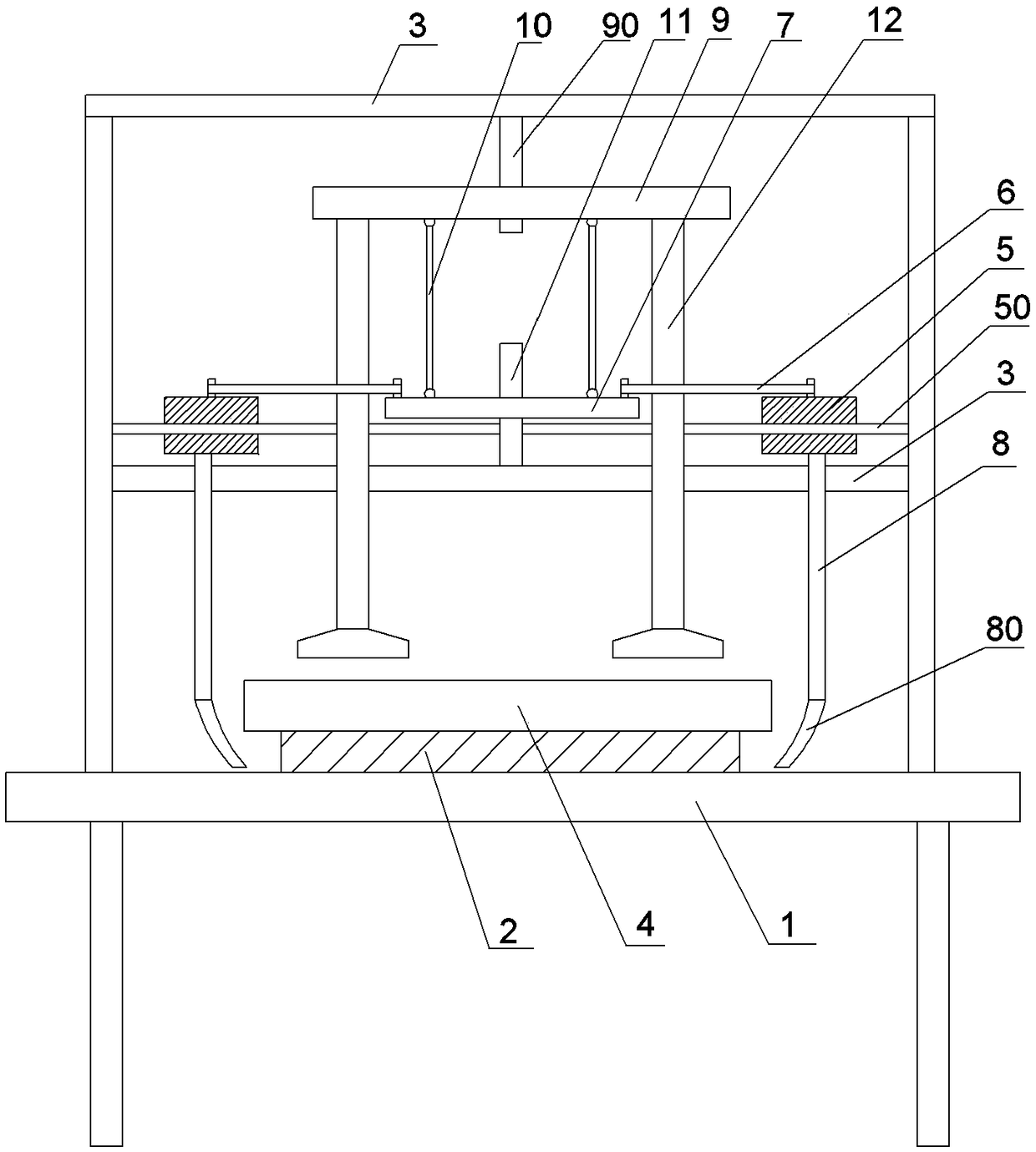

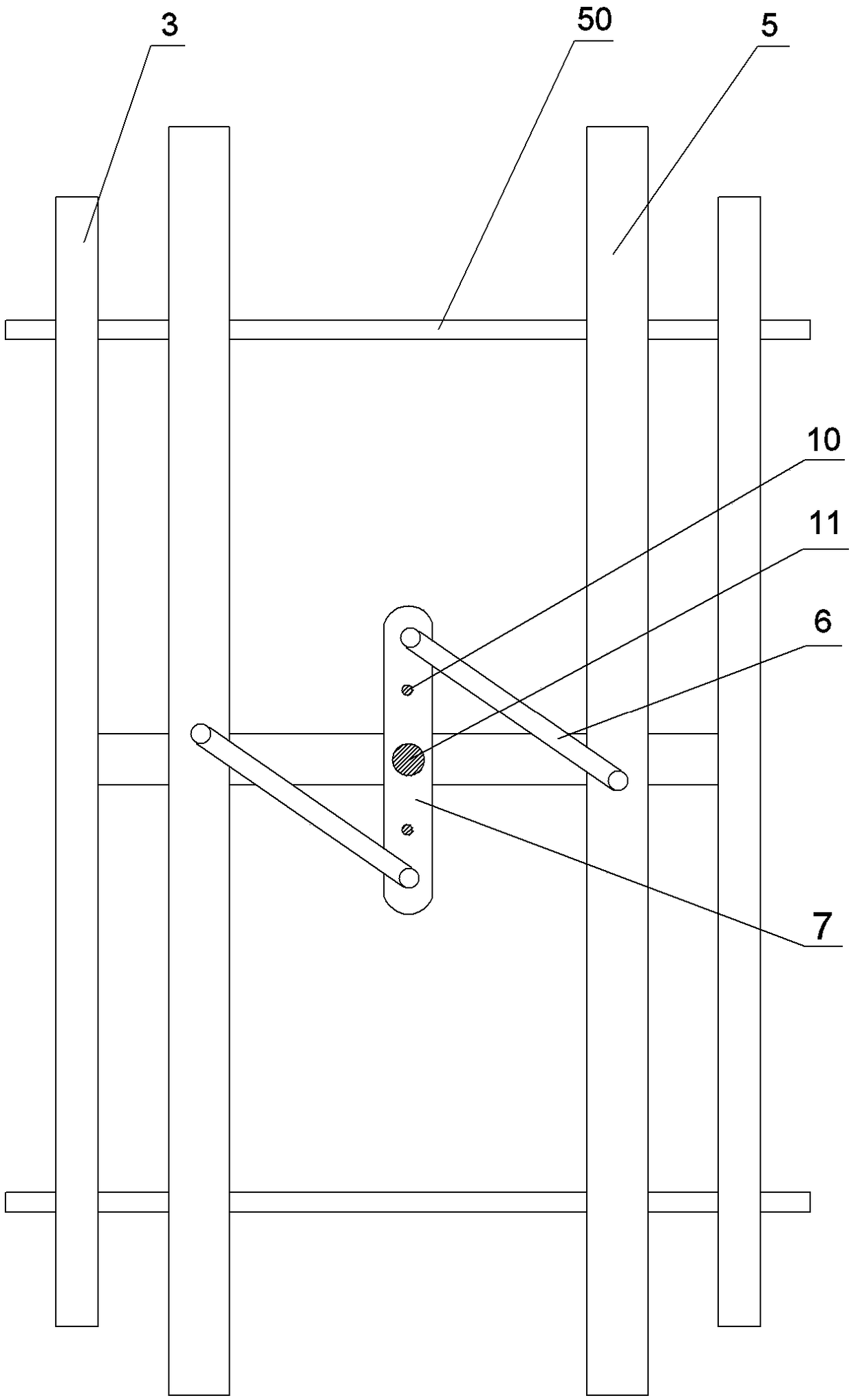

[0021] The reference signs in the drawings of the description include: frame 1, conveyor belt 2, fixed seat 3, workpiece 4, sliding seat 5, guide rod 50, first connecting rod 6, turret 7, jaw 8, bending part 80 , sliding frame 9, support shaft 90, second connecting rod 10, rotating shaft 11, elastic pressure bar 12.

[0022] Such as figure 1 and figure 2 As shown, the vehicle-mounted clamping and conveying device of this embodiment includes a frame 1, on which a fixed seat 3 is detachably connected, and on the fixed seat 3, two guides distributed along the length direction of the fixed seat 3 are fixedly arranged. rod 50, and two guide rods 50 all extend along the width direction of fixed base 3, are provided with two parallel sliding seats 5 between two guide rods 50, have two sliding seats 5, and two sliding seats 5 all wear Pass two two guide rods 50, and can slide on two guide rods 50. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com