Self-air-inflation packaging bag

A self-inflating, bag body technology, applied in the field of packaging bags, can solve the problems of troublesome use, large space occupation, high storage and transportation costs, and achieve the effects of convenient use, avoiding collision and extrusion, and reducing transportation costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The preferred embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

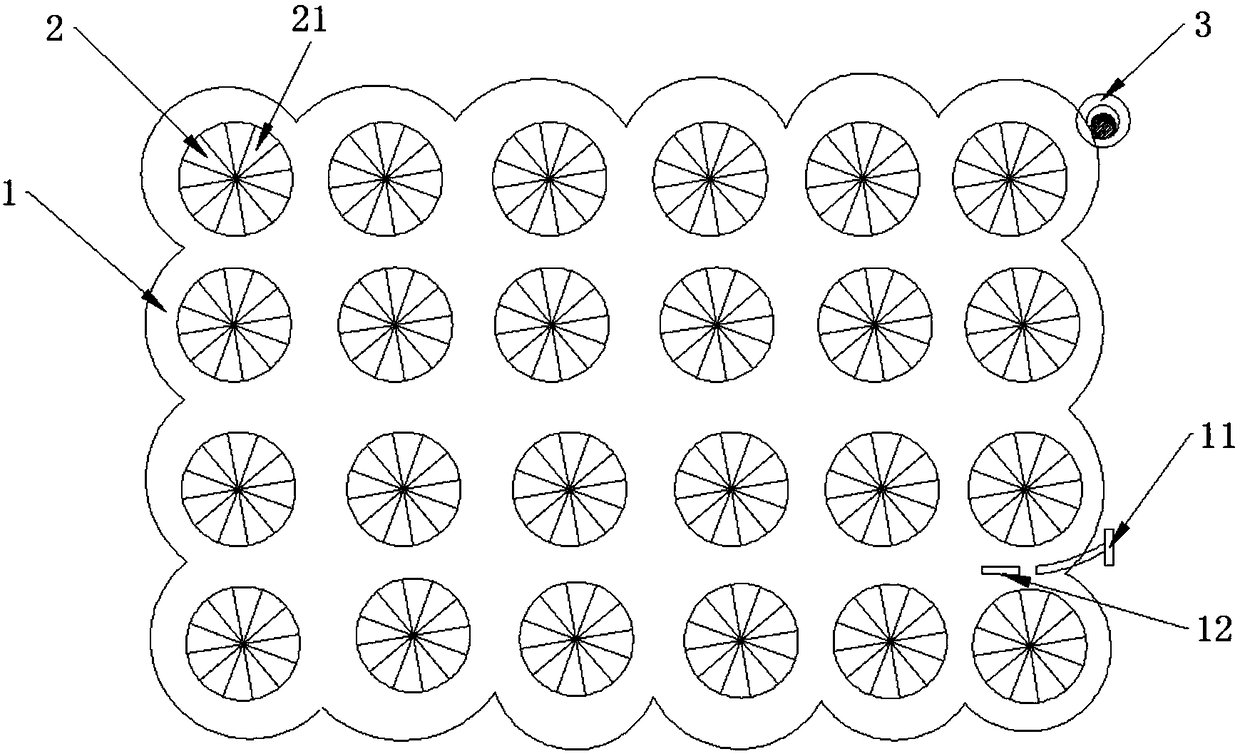

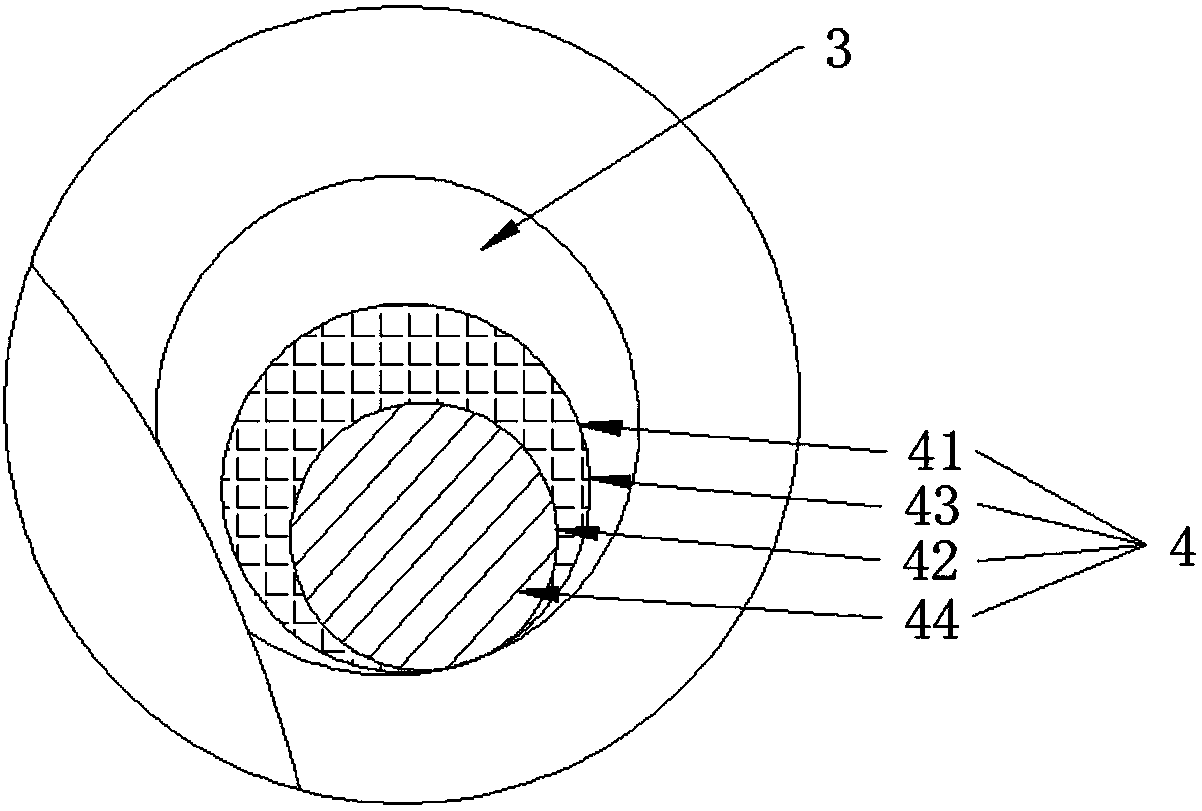

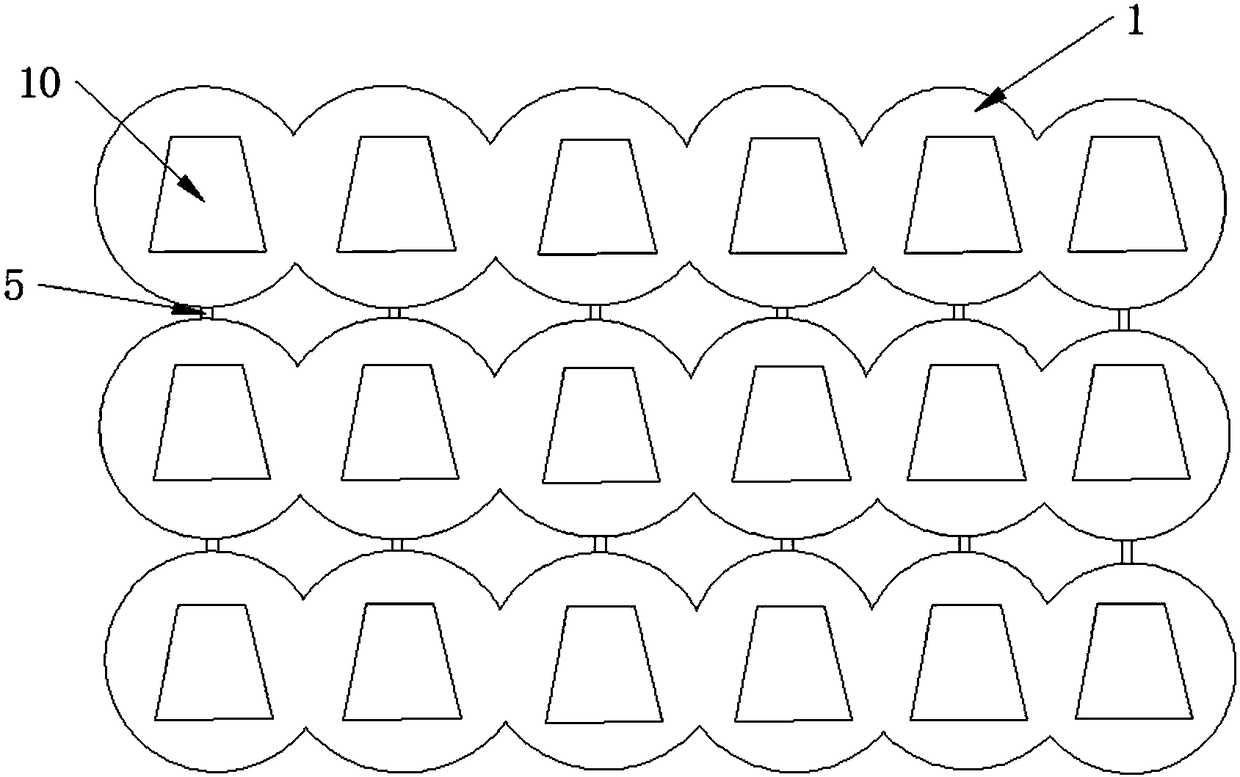

[0022] Such as Figure 1 to Figure 3 As shown, the present invention provides a preferred embodiment of a self-inflating packaging bag.

[0023] Specifically, and refer to figure 1 , A self-inflating packaging bag, the packaging bag includes a bag body 1 provided with a plurality of grooves 2 for placing products 10, the packaging bag also includes a bag body 1 The accommodating part 3 is provided with a self-inflating structure 4. The user stuffs the product 10 into the groove 2 and the product 10 is fixed, and then pinches the self-inflating structure 4 placed in the accommodating part 3, and the self-inflating structure 4 is crushed and releases gas into the capsule 1. The capsule 1 expands and squeezes the product 10, and the product 10 is further fixed. In the subsequent transportation, since the product 10 is firmly fixed, bumps and colli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com