Fixed-length cutting device for bamboo batten for lantern producing

A bamboo strip and sizing technology, used in mechanical equipment, forming/shaping machines, wood processing appliances, etc., can solve the problems of reducing production efficiency, labor consumption, manual measurement, etc., to increase production efficiency, facilitate replacement and maintenance, Easy-to-control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

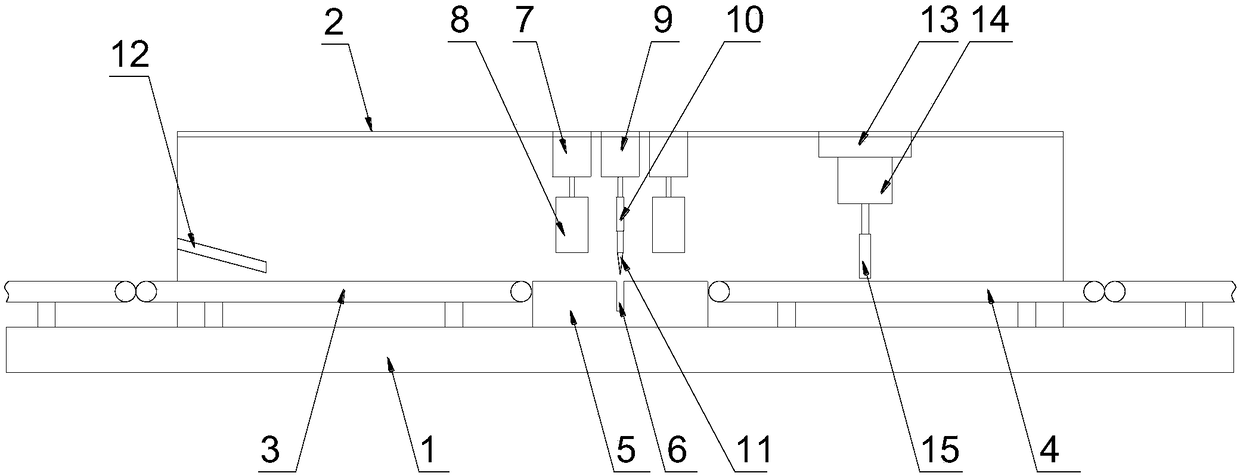

[0018] like figure 1 as shown, figure 1 It is a structural schematic diagram of a bamboo strip cutting-to-length equipment for lantern production proposed by the present invention.

[0019] refer to figure 1 , a kind of bamboo strip cutting equipment for lantern production that the present invention proposes, comprises workbench 1, frame 2, feed conveyer belt 3, fixed table 5, discharge conveyer belt 4, two groups of pressing components, cutting device and positioning device;

[0020] The feed conveyor belt 3, the fixed table 5 and the discharge conveyor belt 4 are sequentially arranged on the worktable 1 along the working direction, and the working surfaces of the feed conveyor belt 3, the fixed table 5 and the discharge conveyor belt 4 are located on the same horizontal plane;

[0021] The middle part of the fixed table 5 is provided with a slot 6, the extension direction of the slot 6 is perpendicular to the working direction, and the slot 6 forms openings on both sides ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com