Steel strip clamping device

A clamping device and steel strip technology, which is applied in the field of mechanical processing, can solve the problems of reduced drilling accuracy, inability to clamp the steel strip, and affect operation, etc., and achieve the effects of simple and compact structure, stable device structure, and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

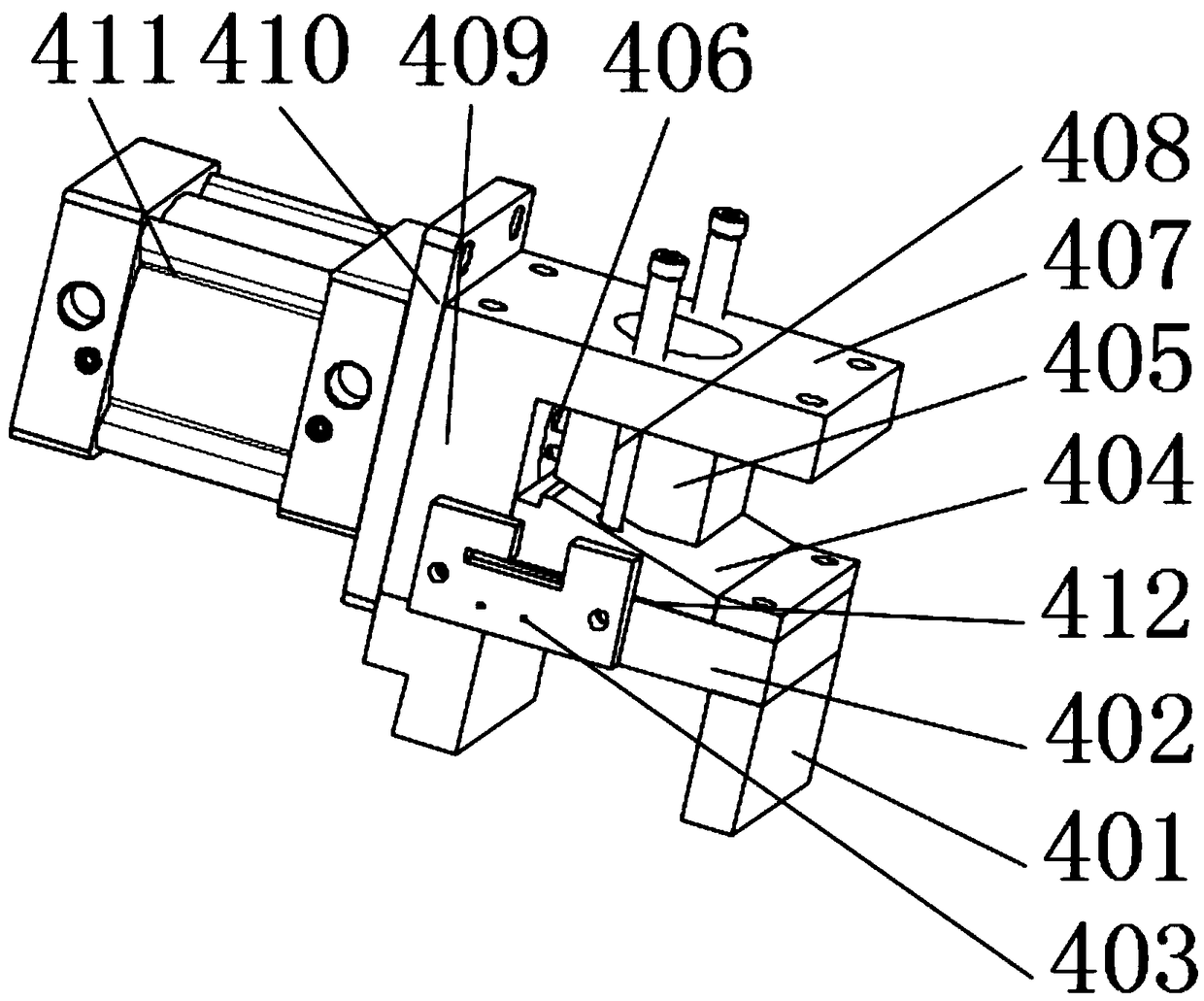

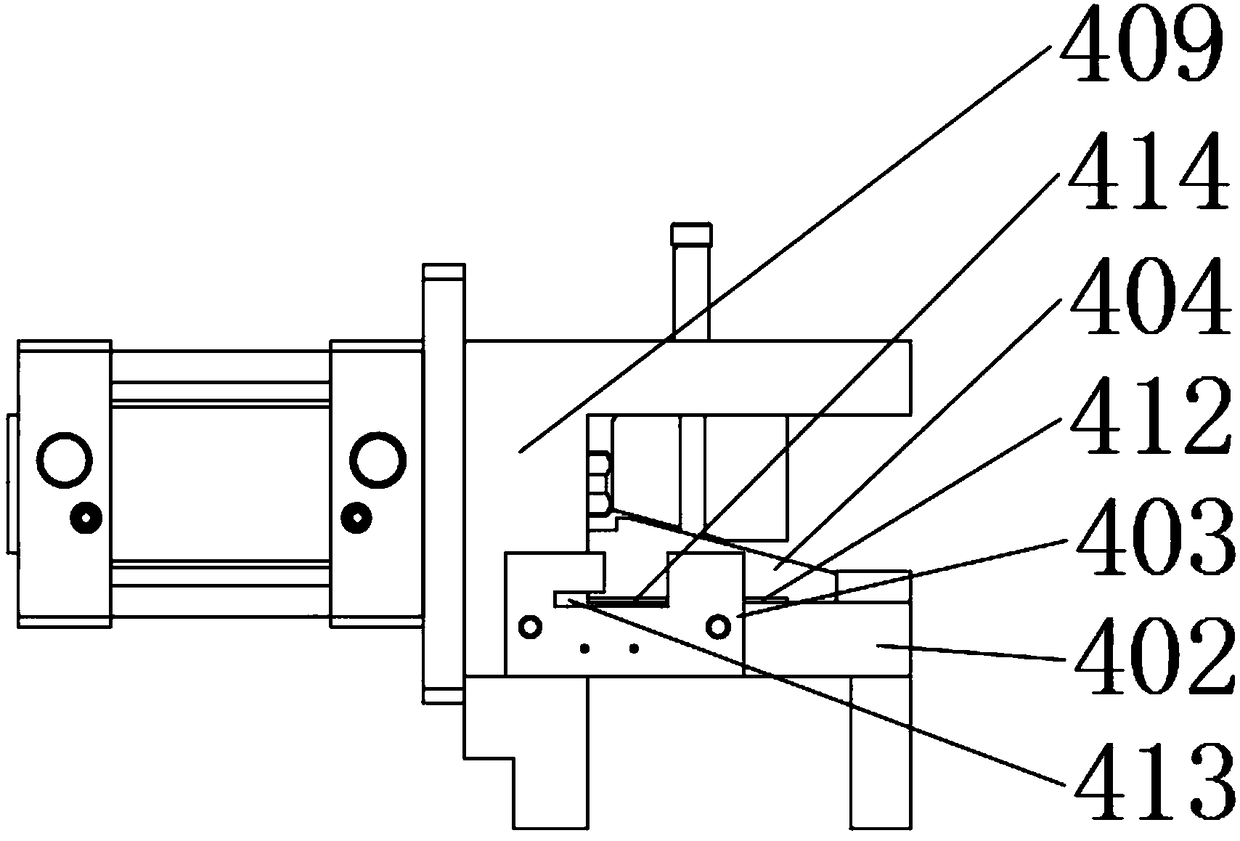

[0026] refer to Figure 1 to Figure 4 As shown, the present invention discloses a steel strip clamping device, which includes a fixed block 401, a base set on the fixed block 401, and a right-angled U-shaped structure formed integrally with the base, including a lower base 402, a side base 409 and an upper base 407. Two guiding columns 408 are fixedly connected to the upper surface of the lower base 402 , and the guiding columns 408 are arranged perpendicular to the lower base 402 . Between the upper base 407 and the lower base 402, a clamping block 404 with an inclined surface is arranged, and the lower surface of the clamping block 404 is provided with an upwardly concave rectangular groove 412 in the direction of steel strip transmission, and the rectangular groove 412 is used to place the steel strip . Two holes are provided inside the clamping block 404 , and the guide post 408 is sheathed in the hole of the clamping block 404 , and the clamping block 404 can move back ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com