Device and method for extracting cable core

A cable and cable technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of cable insulation layer and shielding layer deformation damage, affecting the overall efficiency of cable testing, and affecting the accuracy of test results, etc., to achieve The cable is fixed stably, the working time is short, and the force is uniform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

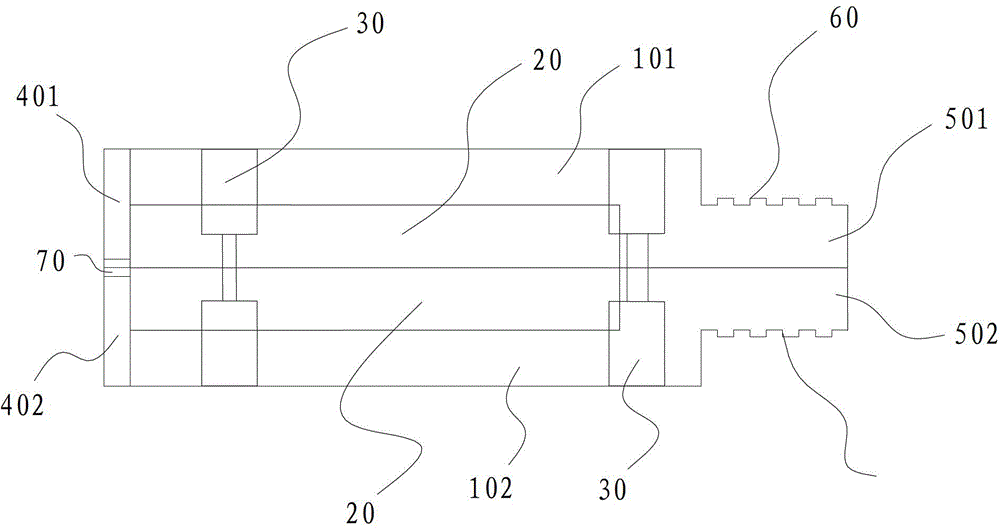

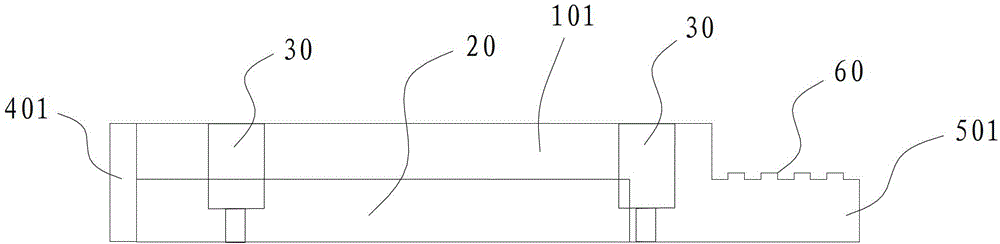

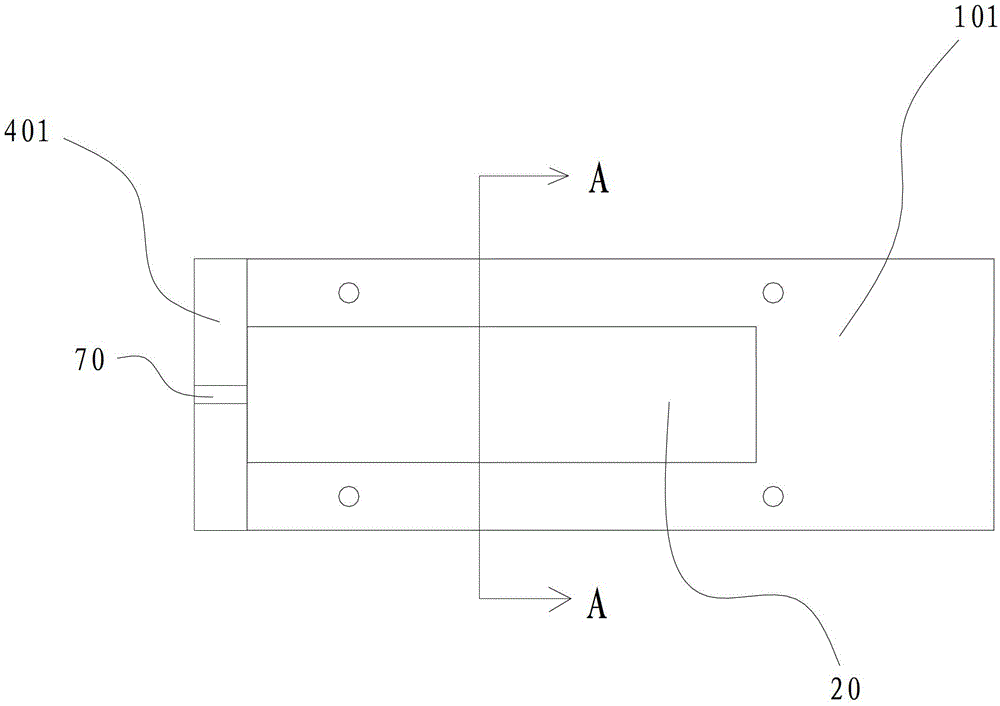

[0031] Such as Figure 1 to Figure 5 As shown, a device for pulling out a cable core includes a bar-shaped cable clamping body, and one end of the cable clamping body is provided with a cable fixing cavity along its length. The end of the cable clamping body with the cable fixing cavity is fixed with a cable fixing pressing piece, and the center of the cable fixing pressing piece is provided with a central hole 70 through which the cable core can pass. The other end of the cable clamping body is provided with a clamping palm for clamping by the tension machine.

[0032] In this example, if figure 1 As shown, the cable clamping body is fixed by a left clamping body 101 and a right clamping body 102, and one end of the left clamping body 101 and the right clamping body 102 is respectively provided with a semi-cylindrical clamping cavity 20 , the cable fixing cavity is composed of clamping cavities 20 respectively provided on the left clamping body 101 and the right clamping bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com