A steel-aluminum connection mold

A mold, steel-aluminum technology, applied in the field of steel-aluminum connection molds, can solve problems such as short service life, pollution, and low load-bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

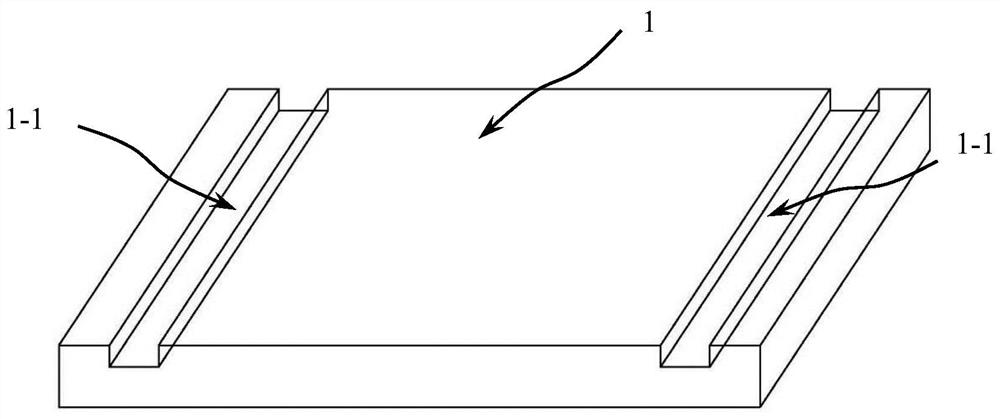

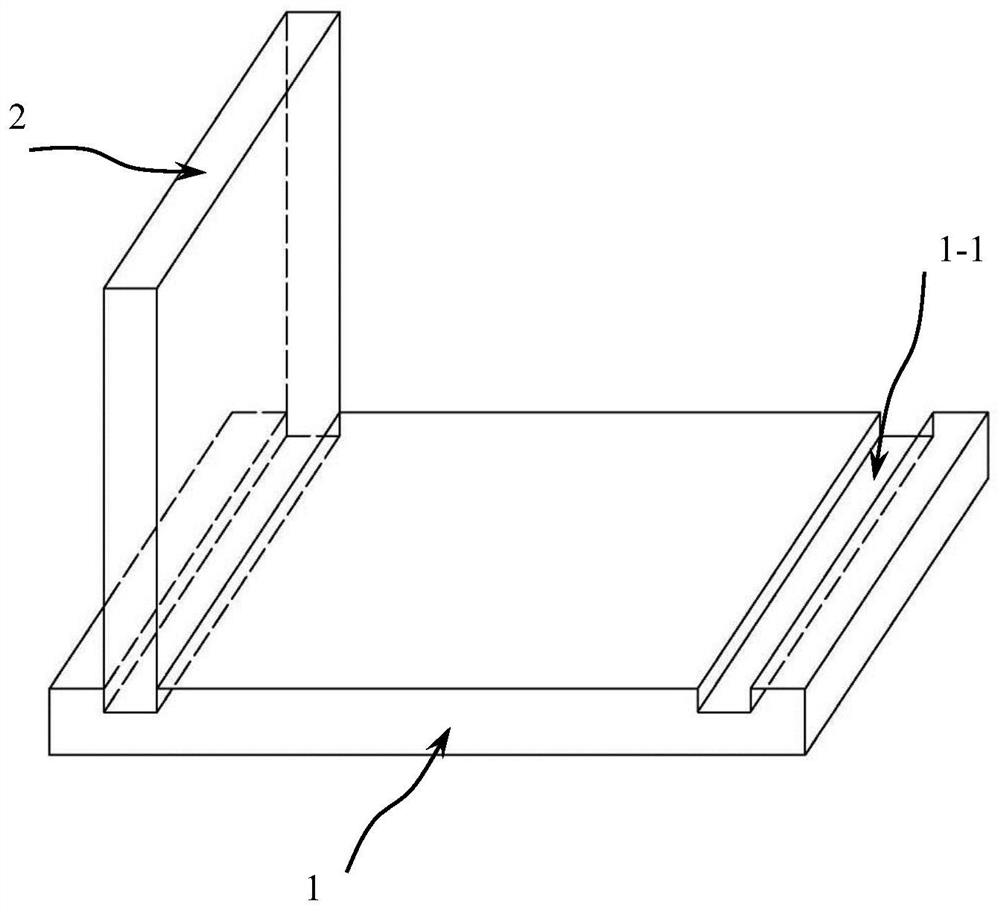

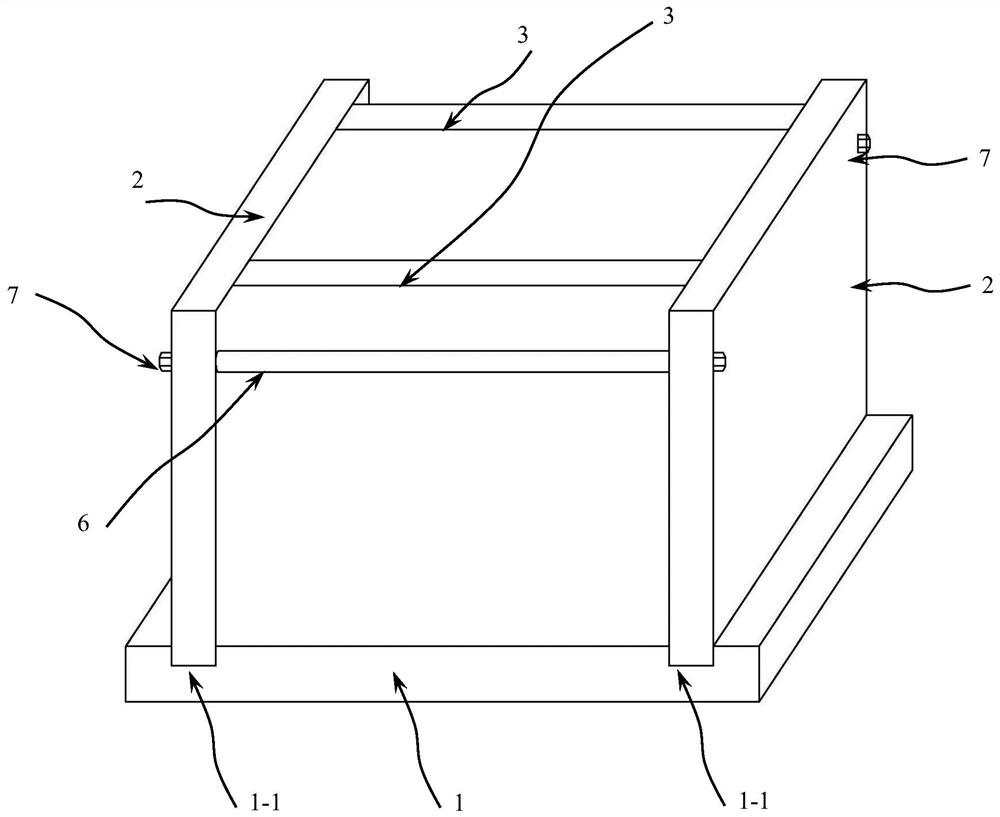

[0040] refer to Figure 1 to Figure 5 , a steel-aluminum connection mold, including a bottom formwork 1, a bottom formwork groove 1-1, two side formworks 2, two side formworks 3, a top formwork 4, a convex module 5, a horizontal tie rod 6, a nut 7 and a vertical tie rod 8; the bottom of the side template 2 is inserted into the groove 1-1 of the bottom template, and the two side templates 3 are respectively inserted between the two side templates 2; the two side templates 2 are fixed by several tie rods 6 and nuts 7; the top template 4 and Bottom formwork 1 is fixed by several vertical tie rods 8 and nuts 7; One end of top formwork 4 is closed with one side formwork 2, and opening 5-1 is formed between the other end of top formwork 4 and other side formwork 2, and convex module 5 can pass through Through the opening 5-1. The bottom of the top template 4 is provided with an exhaust port 4-1. The top of the side template 2 on one side of the opening 5-1 is provided with an alum...

Embodiment 2

[0042] refer to Figure 6 ~ Figure 10 , a steel-aluminum connection mold, including a bottom formwork 1, a bottom formwork groove 1-1, two side formworks 2, two side formworks 3, a top formwork 4, a convex module 5, a horizontal tie rod 6, a nut 7 and a vertical tie rod 8; the bottom of the side template 2 is inserted into the groove 1-1 of the bottom template, and the inner side of the side template 2 is provided with a side template groove 2-1 near both sides, and the two ends of the two side templates 3 are respectively inserted into the groove 2-1 of the side template; The block side formwork 2 is fixed by several tie rods 6 and nuts 7; the top formwork 4 and the bottom formwork 1 are fixed by several vertical tie rods 8 and nuts 7; one end of the top formwork 4 is closed with the side formwork 2, and the other end of the top formwork 4 and An opening 5-1 is formed between the templates 2 on the other side, and the convex module 5 can pass through the opening 5-1.

[0043...

Embodiment 3

[0045] The using method of embodiment 1 mould,

[0046] Mold assembly, the bottoms of the two side formworks 2 are respectively inserted into the grooves 1-1 of the bottom formwork, the two side formworks 3 are inserted between the two side formworks 2, steel connectors 9 are put in, and the distance between the two side formworks 3 is adjusted , so that the inner surface of the side formwork 3 is in close contact with the steel connector 9; the two side formworks 2 are fixed by the tie rod 6 and the nut 7; the top formwork 4 and the bottom formwork 1 are fixed by the vertical tie rod 8 and the nut 7;

[0047] The molten aluminum is poured, the molten aluminum is poured through the opening 5-1 to fill the cavity of the mold, and pressed into the convex module 5, the air in the cavity of the mold is discharged from the exhaust port 4-1 or the aluminum discharge port 2-2. The molten aluminum is discharged through the aluminum discharge port 2-2;

[0048] To set the shape, remove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com