A particle screening machine and its screening method

A screening machine and particle technology, applied in chemical instruments and methods, sieves, solid separation, etc., can solve the problems of low degree of automation, poor cleaning effect of sieve tray, poor screening effect of small particles, etc., and achieve good cleaning effect. , The effect of promoting particle separation and increasing vibration frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the drawings and descriptions of the drawings.

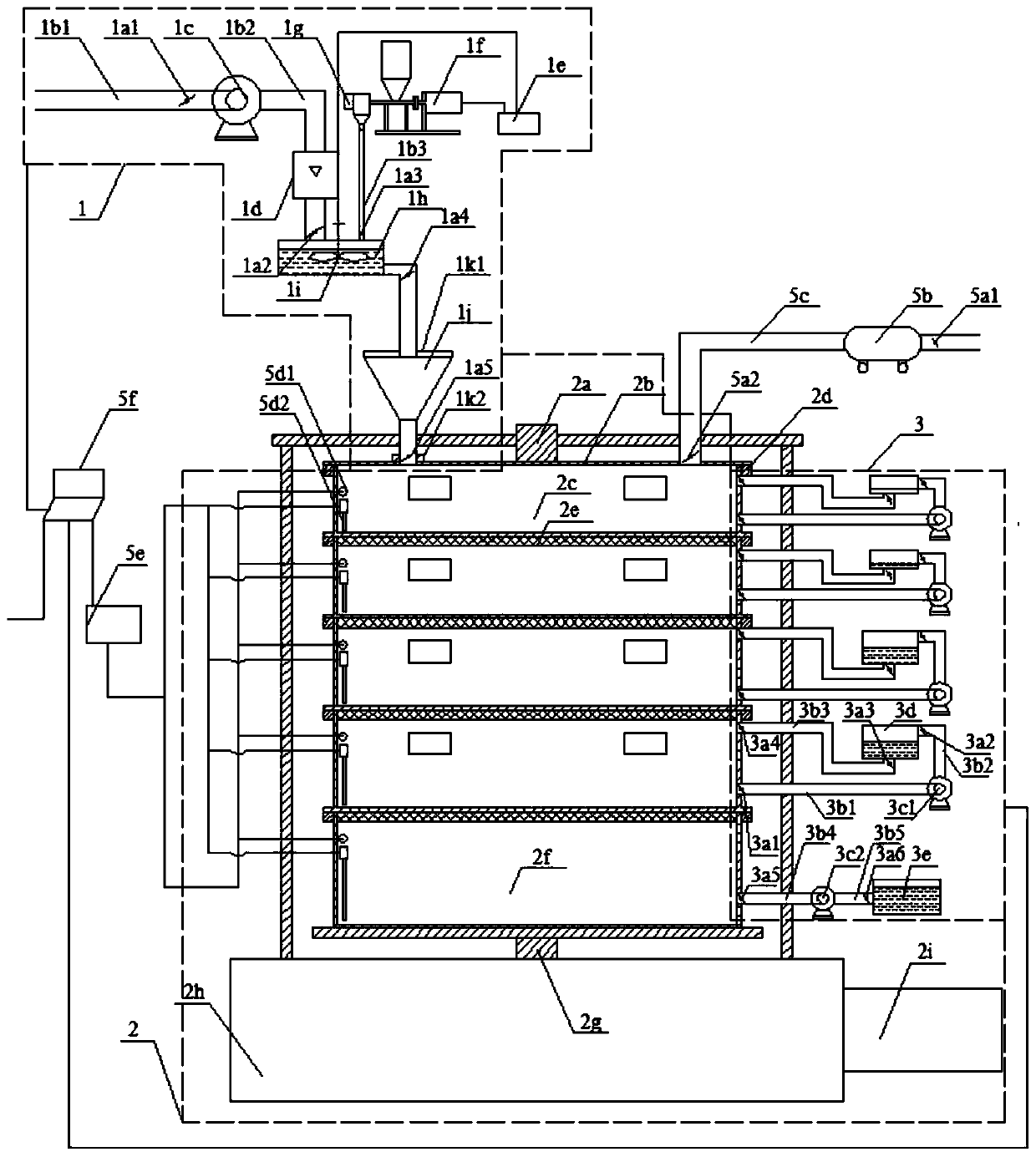

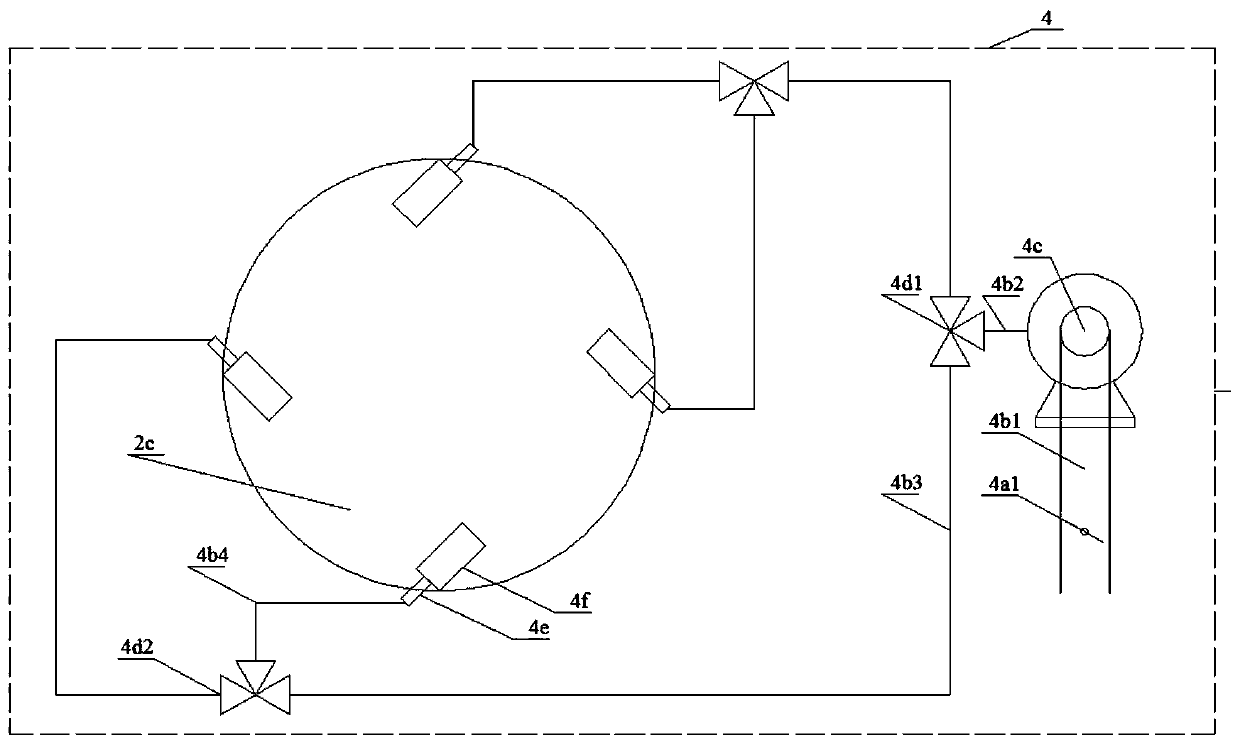

[0034] A particle screening machine, comprising a slurry conveying device 1 , a screening device 2 , a slurry return device 3 , a cleaning device 4 , and a monitoring control device 5 .

[0035] Wherein, the slurry conveying device 1 includes a first liquid conveying valve 1a1, a first liquid conveying pipe 1b1, a liquid conveying pump 1c, a second liquid conveying pipe 1b2, a flow meter 1d, a second liquid conveying valve 1a2, a frequency conversion device 1e, a Powder device 1f, vibration device 1g, powder delivery pipe 1b3, powder delivery pipe outlet regulating valve 1a3, liquid slurry mixing device 1h, liquid slurry stirring device 1i, funnel inlet regulating valve 1a4, funnel 1j, funnel sealing cover 1k1, funnel outlet adjustment Valve 1a5; the first liquid delivery pipe 1b1 is connected to the second liquid delivery pipe 1b2 through the liqui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com