Multi-direction buckle device

A technology of male and female buckles, applied in belt buckles, fasteners, clothing, etc., can solve problems such as simultaneous release of male buckles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

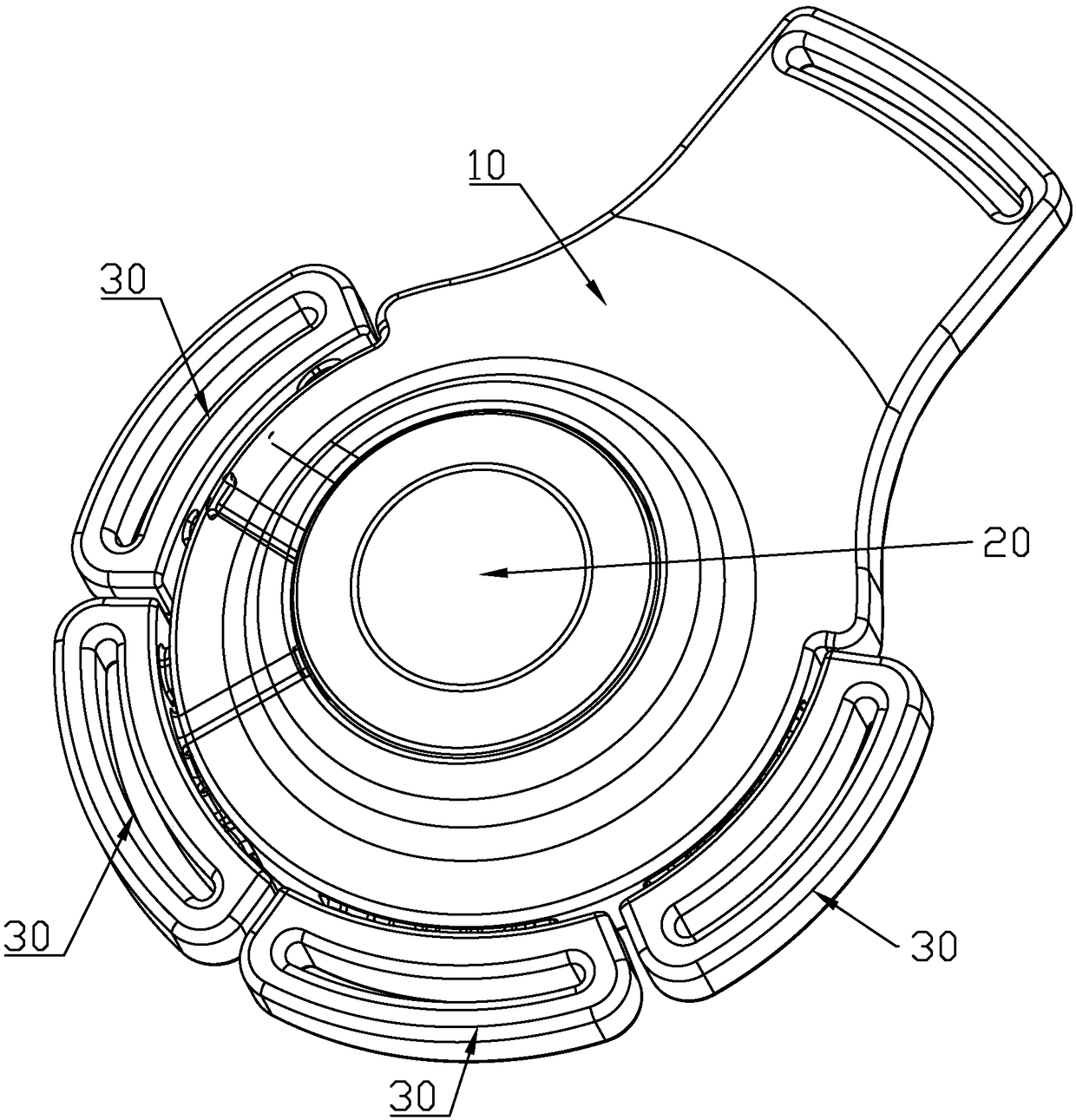

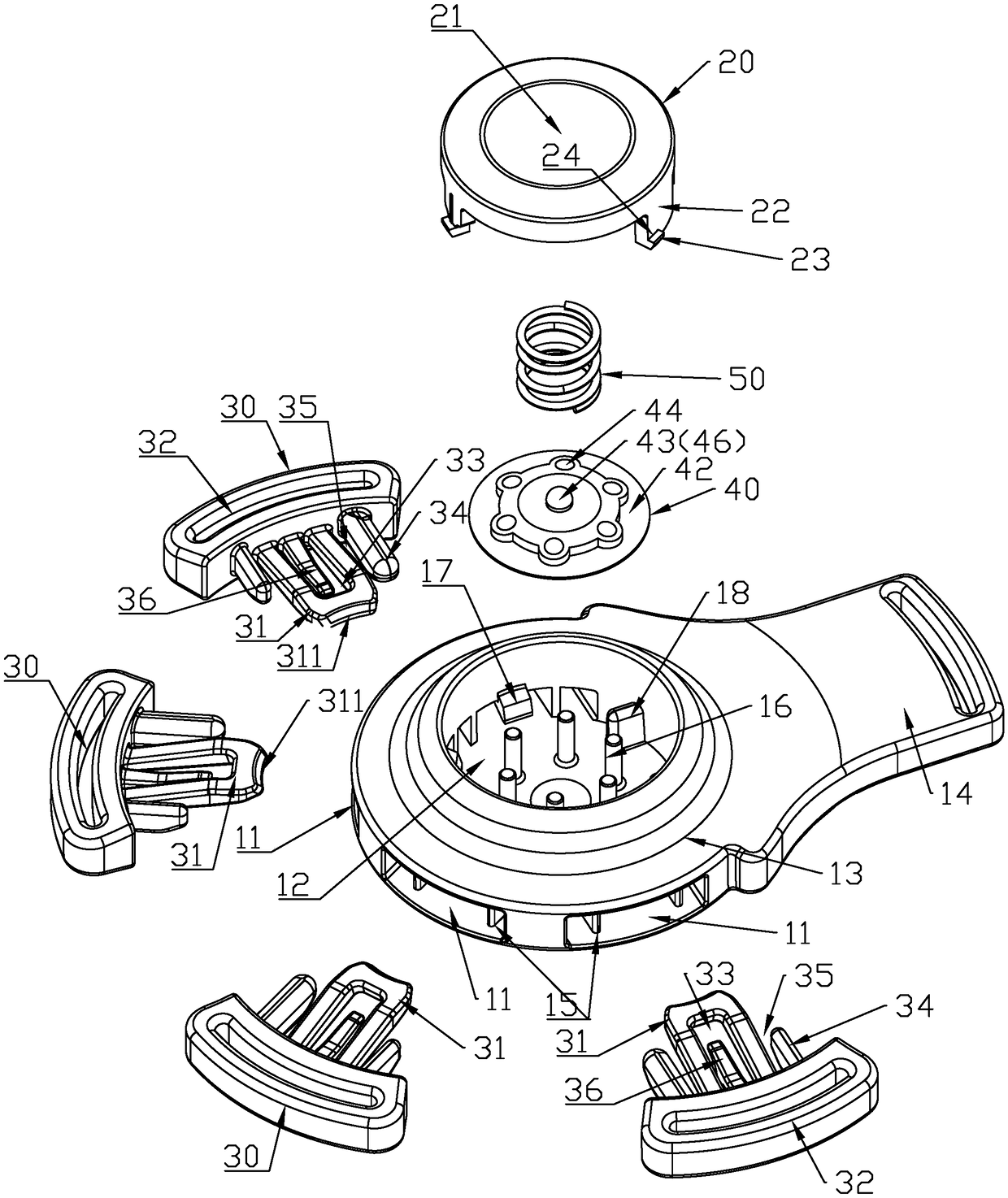

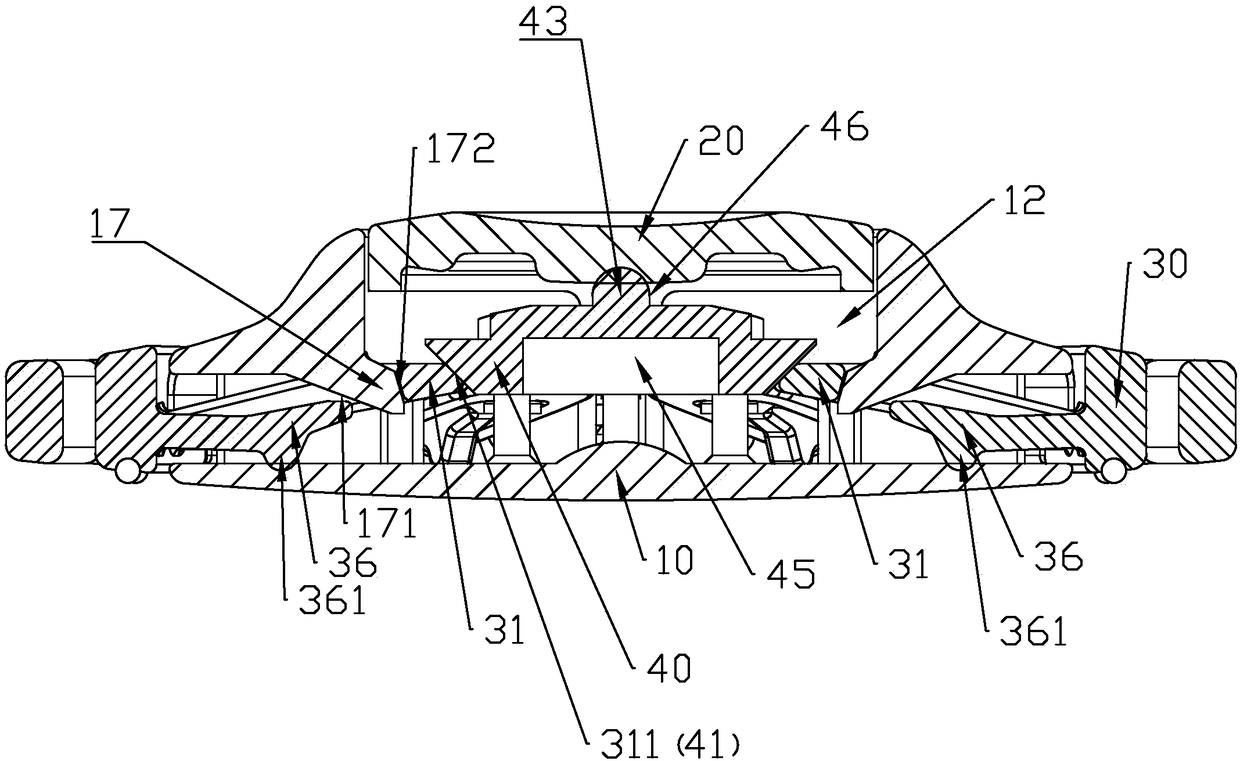

[0032] like Figure 1 ~ Figure 3 As shown, the multi-directional buckle device of this embodiment includes a female buckle body 10 , a button 20 , a male buckle 30 , a force transmission member 40 , and a reset elastic member 50 .

[0033] like figure 2 , Image 6 , Figure 7 , Figure 8 As shown, the female buckle body 10 is provided with a plurality of slots 11 into which the male buckle 30 can be movably inserted and a key slot 12 for accommodating the key 20 . The male buckles 30 can be respectively inserted into the card slots 11 to lock and connect with the female buckle body 10, and the buttons 20 are arranged in the button grooves 12, which are used for pressing to unlock; The force transmission member 40 is arranged between the button 20 and the pressing end 31 of the male button 30, and it is used to distribute the force of the button 20 to each male button 30 evenly, so that each male button 30 can be connected with the male button 30 at the same time. The fem...

Embodiment 2

[0054] like Figure 4 , Figure 5 As shown, the multi-directional buckle device of this embodiment includes a female buckle body 10 , a button 20 , a male buckle 30 and a force transmission member 40 .

[0055] The structures of the button 20 and the male buckle 30 are the same as in the first embodiment.

[0056] like Figure 5 As shown, the structure of the female button body 10 is basically the same as that of Embodiment 1, the difference is that a limiting post 16 is set in the button groove 12 of the female button body 10 in Embodiment 1, and in this embodiment, the button A supporting portion 19 is provided in the slot 12 to replace the limiting post 16 . The supporting portion 19 is enclosed in a circular shape, which can stably support the sphere.

[0057] In this example, if Figure 4 , Figure 5 As shown, the force transmitting member 40 is in the shape of a sphere, and its spherical surface forms the pressing surface 41 and the force bearing surface 46 . Simi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com