Full-automatic fruit processing device

A processing device, fully automatic technology, applied in fruit pitting device, metal processing, vegetable or fruit peeling, etc., can solve the problems of high manual processing intensity, long contact time with fruit, bacteria entrance, etc., to reduce manual contact , reduce the carrying of bacteria, and ensure the effect of eating health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

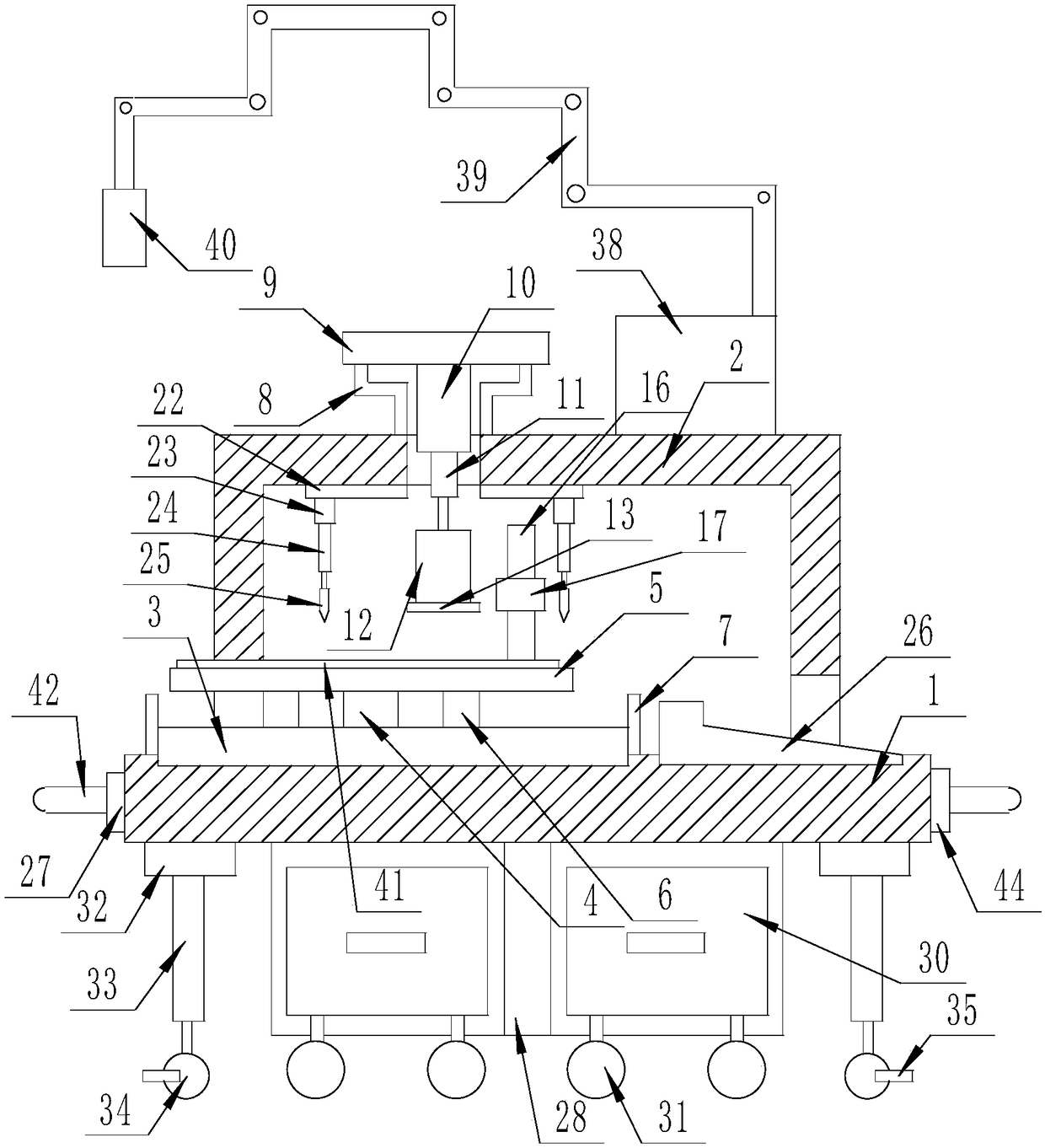

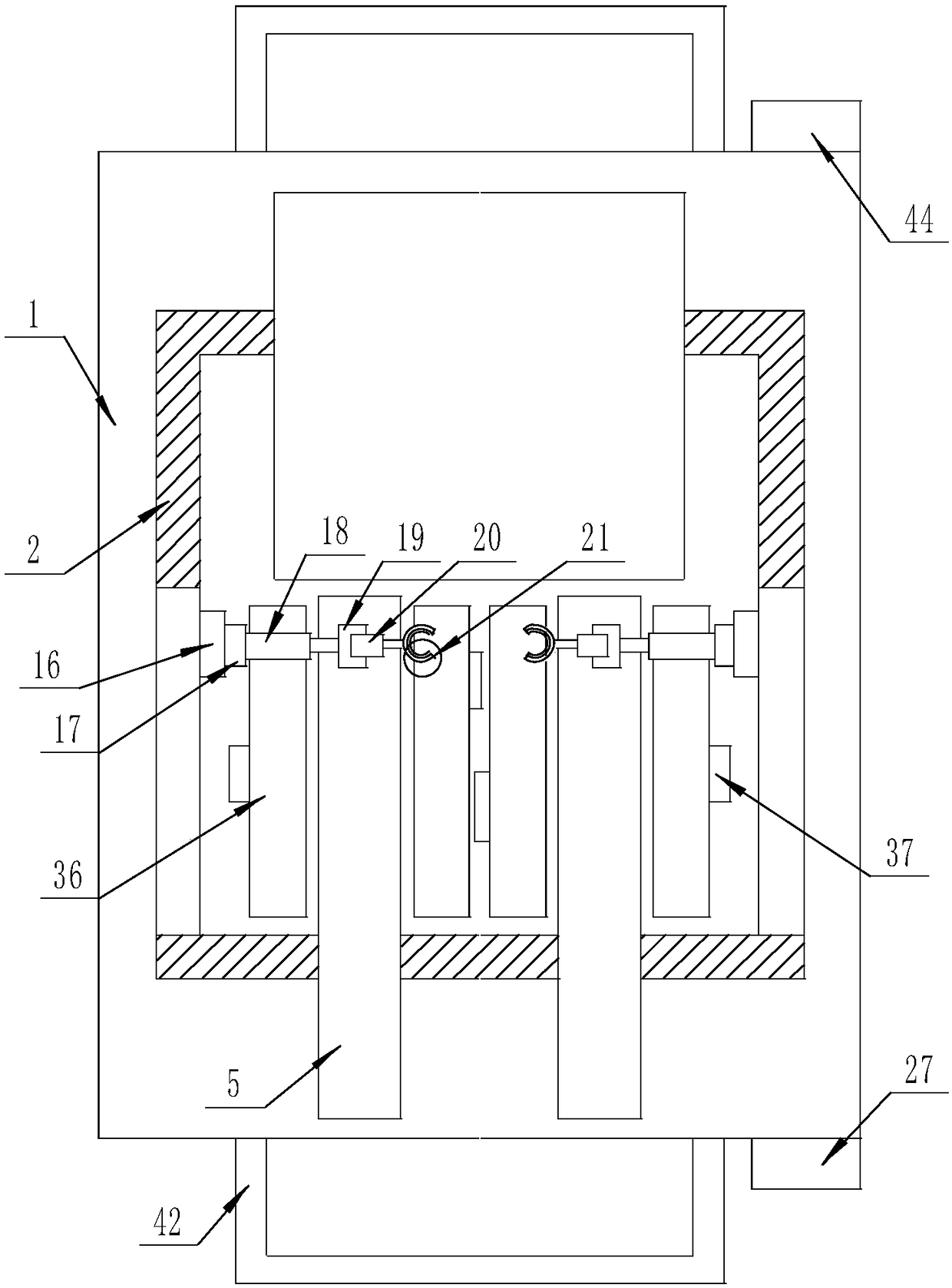

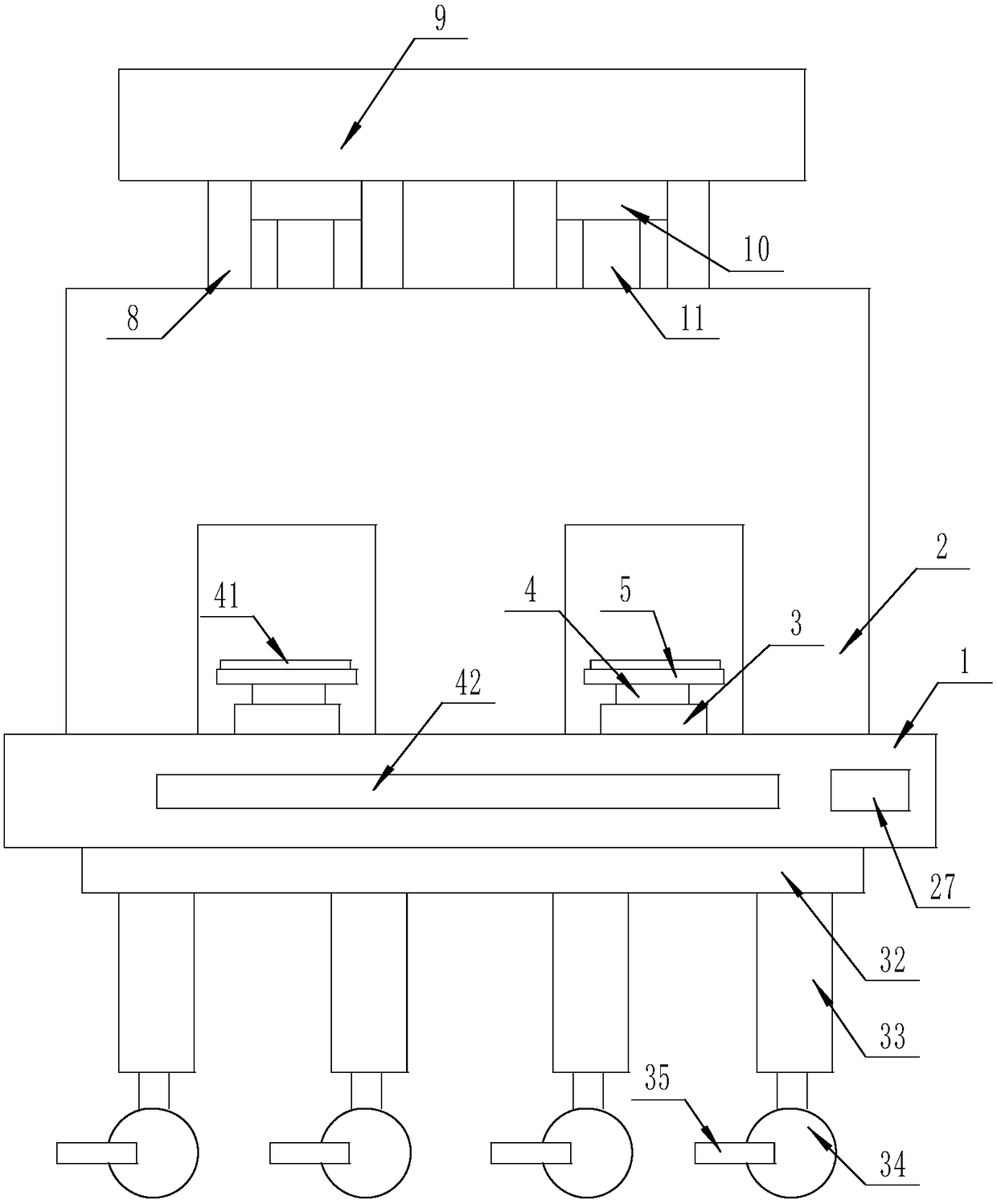

[0023] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-6As shown, a fully automatic fruit processing device comprises a strip bearing plate 1, the upper surface of the strip bearing plate 1 is provided with a fully automatic fruit processing device structure, and the edge of the lower surface of the strip bearing plate 1 is provided with a support Moving mechanism, the lower surface of the strip-shaped carrying plate 1 and the inner side of the supporting moving mechanism are provided with a fruit carrying mechanism, and the fully automatic fruit processing device is composed of a strip-shaped buckle shell 2 fixedly connected to the upper surface of the strip-shaped carrying plate 1, A group of No. 1 strip-shaped openings processed on the left side surface of the strip-shaped button shell 2, horizontal slide rails 3 embedded in the upper surface of the strip-shaped bearing plate 1 and positioned on both sides of each ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com