Plastic bag bundling machine

A strapping machine and plastic bag technology, which is applied to strapping machine parts, strapping materials, paper product packaging, etc., can solve problems such as lack of elasticity, weak connection points, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

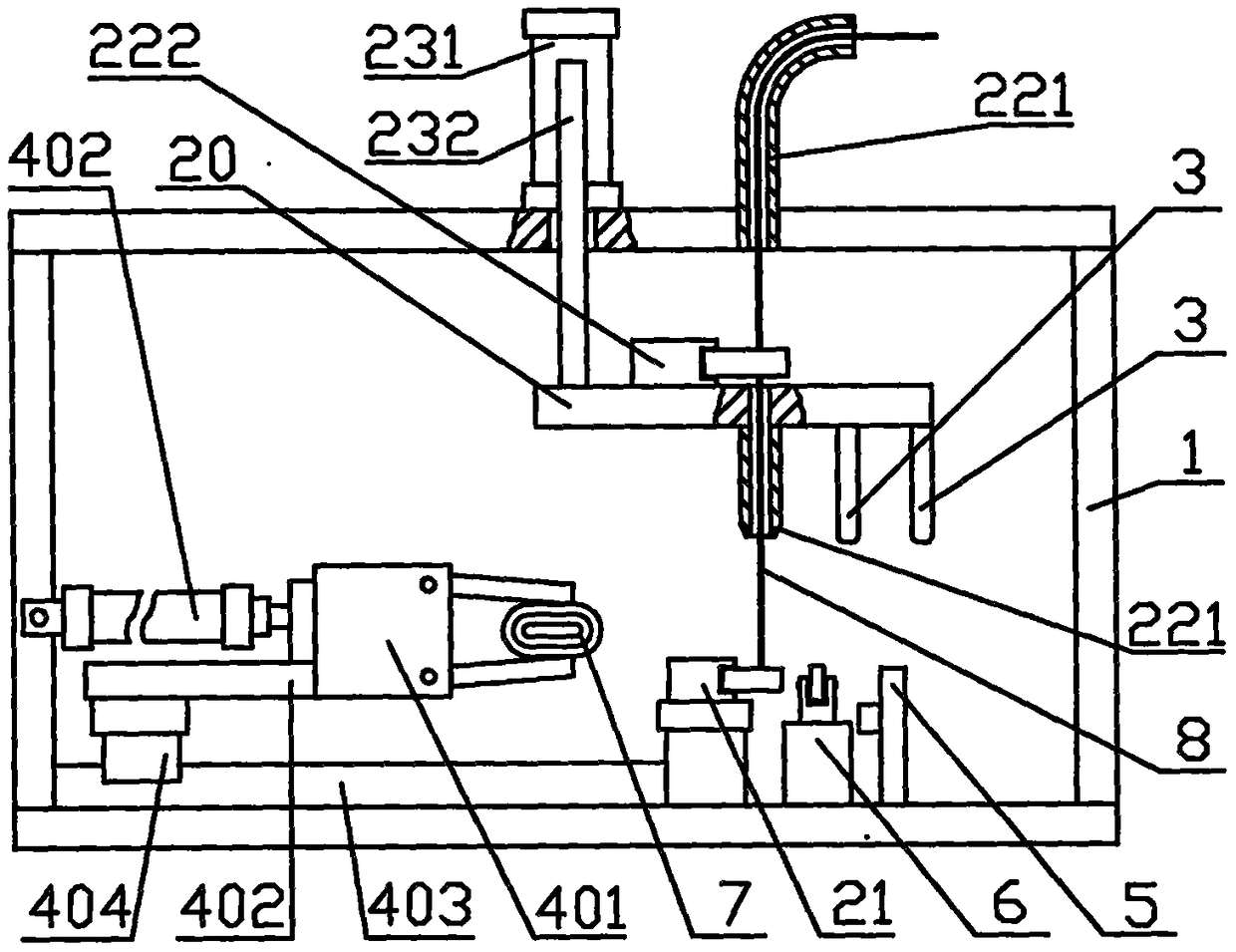

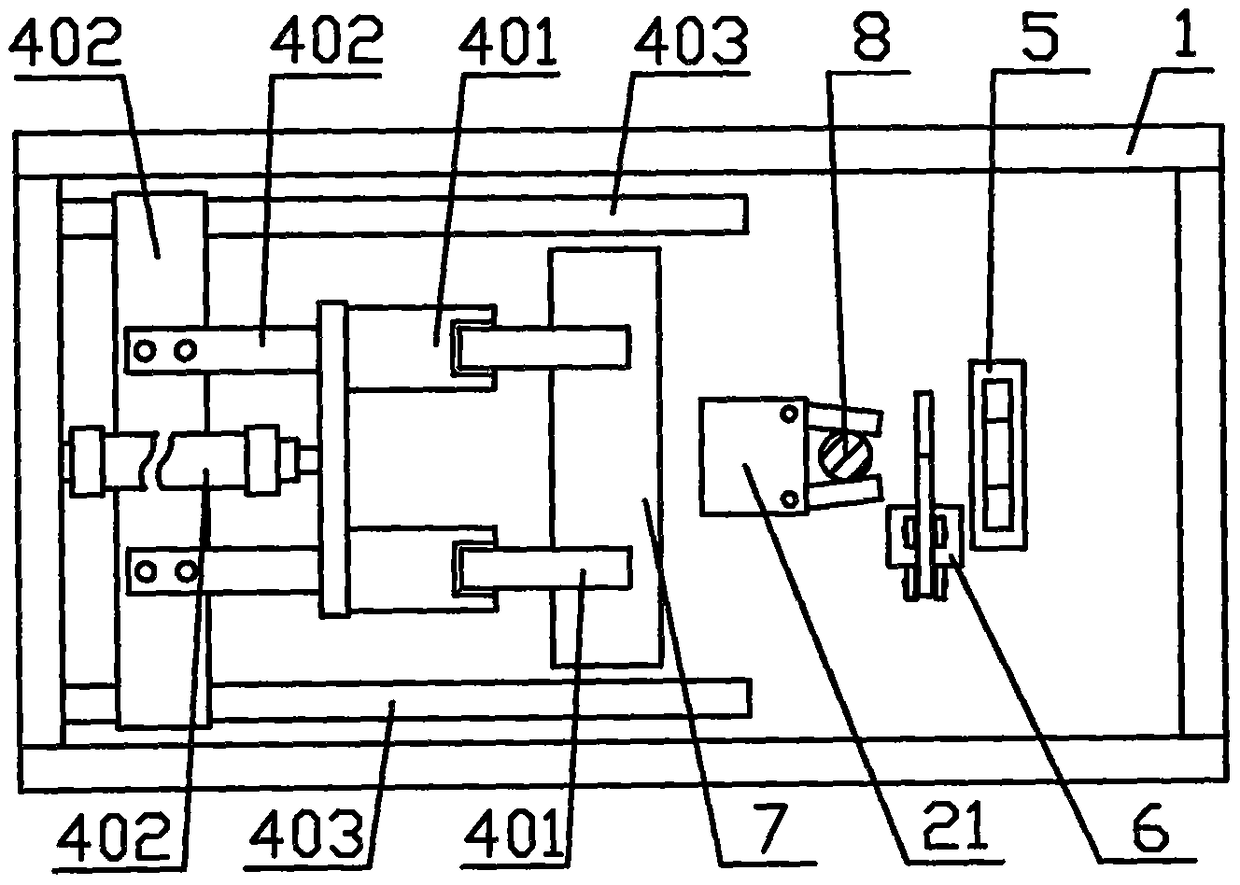

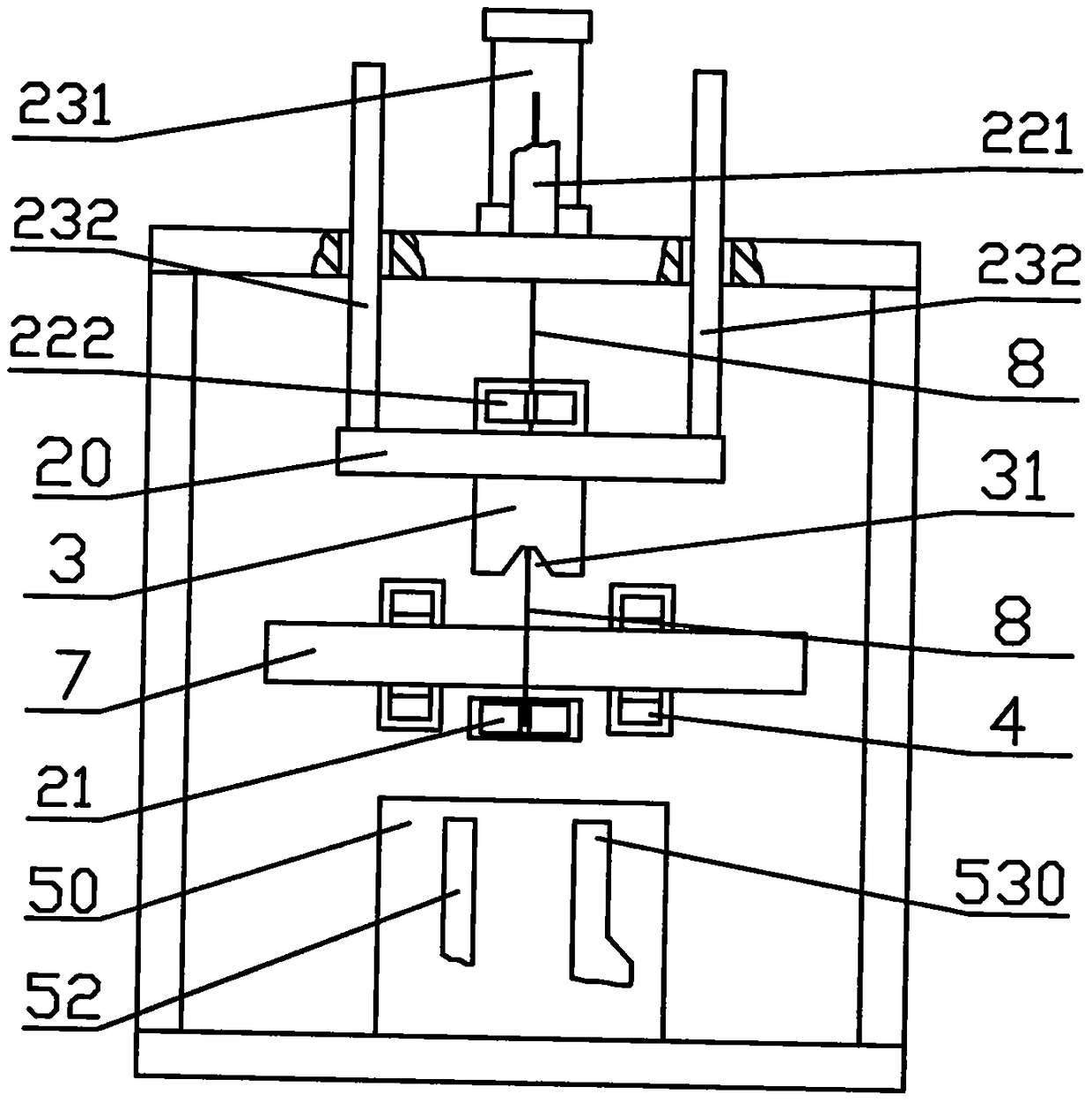

[0066] Embodiment one, such as figure 1 , figure 2 Shown: pay-off device 2 comprises pull wire clip 21, pay-off valve 22, pay-off seat 20, pay-off driving mechanism 23. Its lead wire clamp 21 is a kind of pneumatic finger, and described pneumatic finger 21 is fixedly connected on the described frame 1; Described wire release valve 22 is made of two wire release nozzles 221 and wire release clamp 222, and described The pay-off clamp 22 is a pneumatic finger, a pay-off nozzle 221 and a pay-off clamp 22 are installed on the pay-off seat 20, that is, the pay-off valve is connected to the pay-off seat 20, and the draw-off clip 21 and the release valve 22 are up and down correspond. The pay-off driving mechanism 23 includes a cylinder 231 and a guide rod 232 . The bag passing device 4 is a manipulator mechanism 40, which is arranged on one side of the wire releasing device 2, that is, in front of the wire releasing device; the rear side of the bag passing device 2 is also provid...

Embodiment 2

[0074] Embodiment two, such as Figure 17 to Figure 20 Shown: the difference between embodiment two and embodiment one is: one is that bag passing device is a kind of conveyor belt mechanism, and its structural principle is identical with the conveyor belt mechanism of folding device A. The conveyor belt mechanism is composed of two drive rollers 421, a conveyor belt 42, a swing rod 422, and a swing cylinder 423; The heat-sealing device that constitutes, omits close together plate 3; The 3rd, draw wire clip 21 is made of double-rod cylinder 226 and fixed block 227, and the release clip 22 is made of double-rod cylinder 224 and fixed block 225; The 4th, cutting device 6 is a kind of Eager cutter 66; The 5th, pay-off driving mechanism is a kind of electric slide table 233;

[0075] Such as Figure 17 As shown: an electric slide 223 is installed up and down the frame 1, a pay-off seat 20 is connected to the slide 235 of the electric slide 233, and a biaxial cylinder 224 and a f...

Embodiment 3

[0077] Embodiment three, such as Figure 21 with Figure 22 Shown: the difference between the third embodiment and the first embodiment is: first, the wire clamp 21 is connected on the wire release seat 20, and the miniature cylinder 223 and the wire release nozzle 221 of the wire release valve are fixedly connected on the frame 1, The said pay-off driving mechanism is another electric slide table 233, the pay-off seat 20 is connected on the slide table 235 of the electric slide table 233, and the wire clamp 21 corresponds up and down with the pay-off nozzle 221 of the pay-off valve; The bag device is arranged on the same side of the cutting device 6 and the connecting device 5 and the closing plate 3. The bag passing device is a mechanical arm 41; Body; Its three, cutting device 6 is a kind of pneumatic scissors. Such as Figure 21 As shown: a mechanical arm 41 is installed behind the cutting device 6 and the connecting device 5. The mechanical arm 41 is a conveying device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com