Casting sand removing device

A technology for castings and sand boxes, which is applied in the field of casting desanding devices, can solve the problems of slow casting cleaning speed, low sand cleaning efficiency, and low processing efficiency, and achieve the goals of reducing manual labor, good sand removal effect, and improving efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Further detailed explanation through specific implementation mode below:

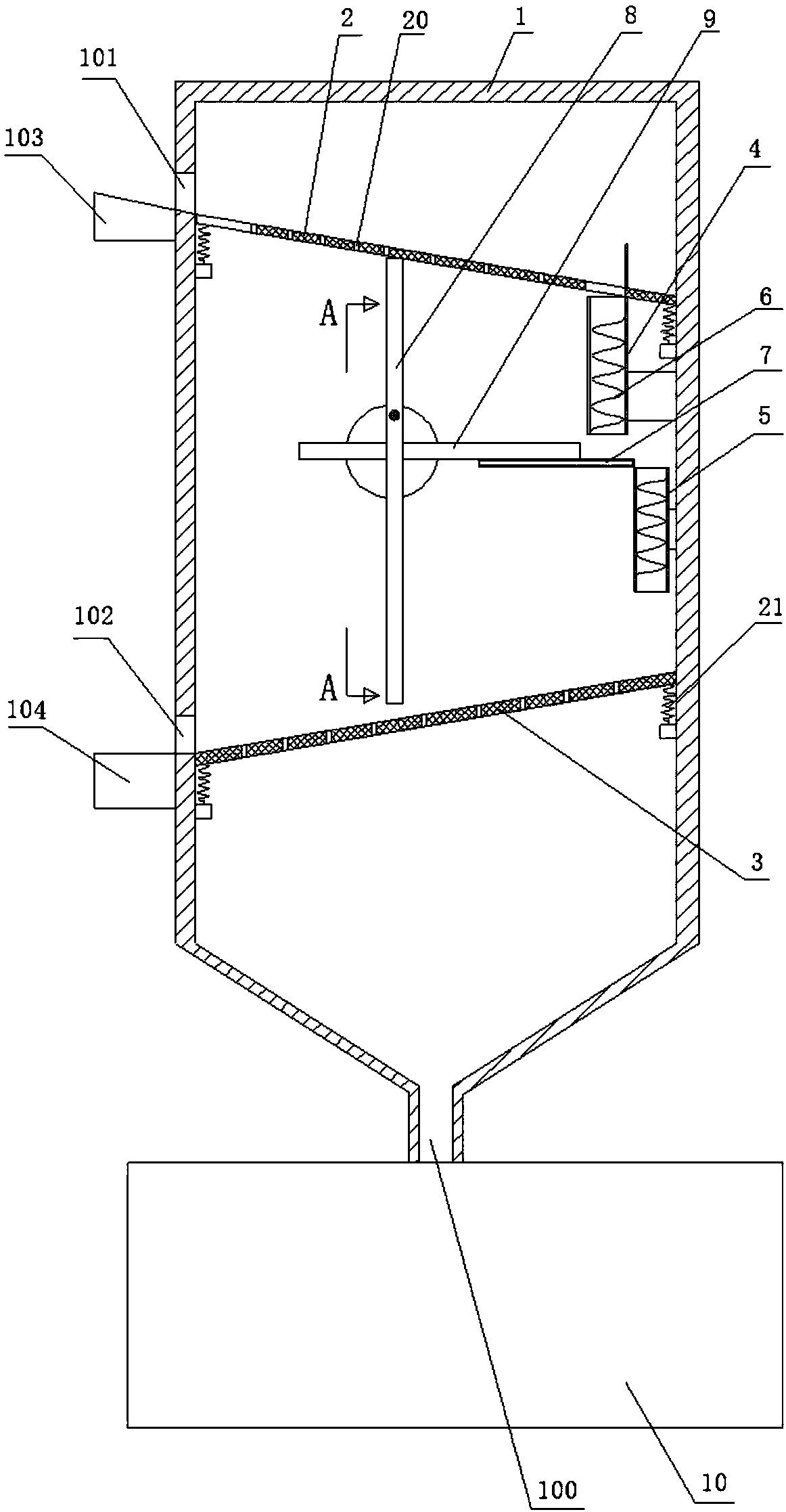

[0022] The reference signs in the drawings of the description include: sand removal box 1, sand discharge port 100, casting inlet 101, casting outlet 102, first support platform 103, second support platform 104, first movable plate 2, sand passage hole 20 , spring 21, second movable plate 3, first channel 4, second channel 5, protrusion 6, receiving groove 7, first push rod 8, first mounting sleeve 80, fourth round pin 81, third round pin 82. The second push rod 9, the second mounting sleeve 90, the sixth round pin 91, the fifth round pin 92, the collection box 10, the third crank 11, the second crank 12, the first crank 13, the second turntable 14, The second drive shaft 140 , the second round pin 141 , the first turntable 15 , the first drive shaft 150 , and the first round pin 151 .

[0023] Such as figure 1 As shown, a casting sand removal device in this embodiment includes a sand removal b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com