Rotary filtration apparatus

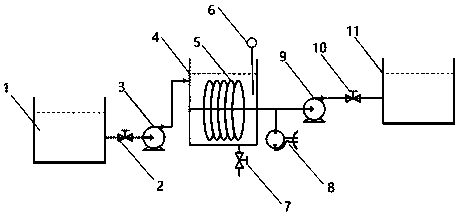

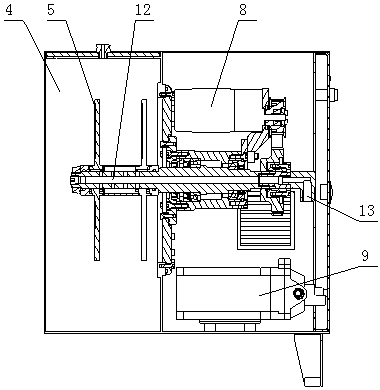

A filter device and filter box technology, which is applied in the field of membrane separation, can solve problems such as shaft fastening and leakage of sealing parts that cannot be detected in time, strength cannot be fully guaranteed, pipelines and circuits are complicated, and achieve anti-clogging and anti-pollution capabilities, Easy disassembly and maintenance, surface self-cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The main characteristics of a river fluid are: pH 7.8, SS 72 mg / L, COD 30 mg / L, turbidity 22 NTU. Using a flat organic ultrafiltration breathable membrane, during the experiment, the membrane flux was maintained at 15-20 LMH, the pH of the product solution was 7.5, the SS was 0 mg / L, the COD was 24 mg / L, and the turbidity was 0 NTU. The removal rate of SS and turbidity is higher than 99%.

Embodiment 2

[0046] The main characteristics of a stone waste liquid are: pH 8.0, SS 2200 mg / L. Using a flat metal microfiltration gas-permeable membrane, during the experiment, the membrane flux was maintained at 400-450 LMH, the pH of the produced liquid was 8.2, the SS was 0 mg / L, the turbidity was 9 NTU, and the liquid quality was stable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com