Non-contact torque measurement device based on counter-magnetostrictive effect

An inverse magnetostrictive, non-contact technology, applied in the field of sensing measurement, can solve the problems of many wires in the sensor, complex structure, shortened service life, etc., and achieve the effect of high-precision dynamic measurement, simple measurement principle and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

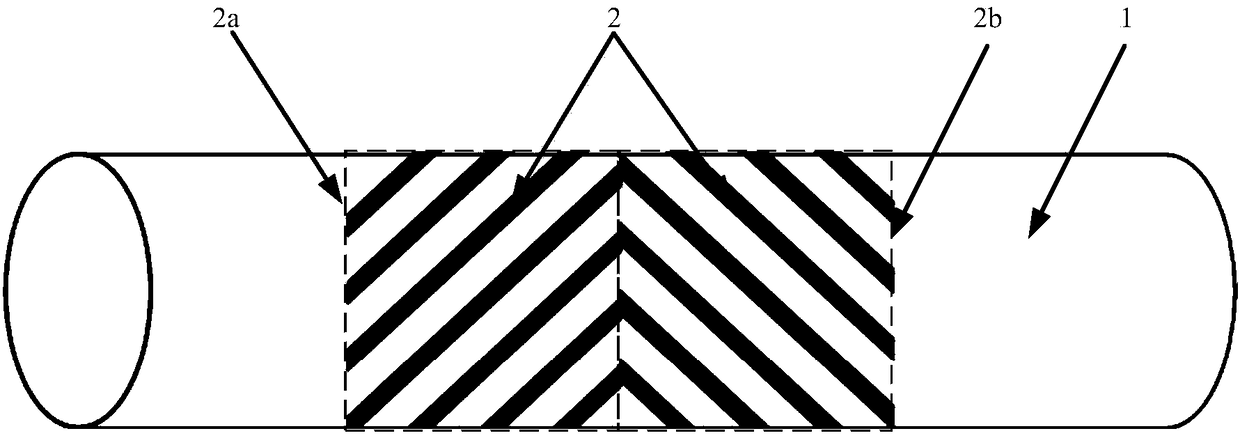

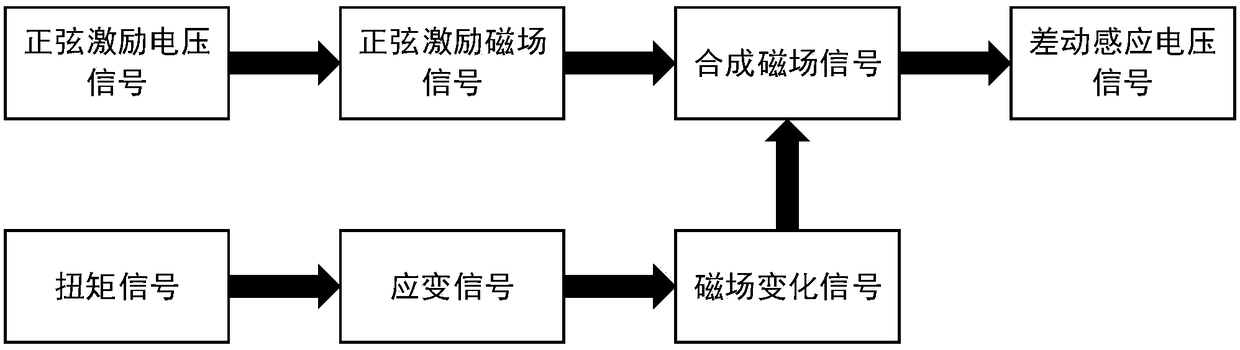

[0040] refer to figure 1 and figure 2 , the non-contact torque measuring device based on the inverse magnetostrictive effect in the present embodiment, the measured rotating shaft 1 of the torque is coated with a giant magnetostrictive material coating strip 2, and the giant magnetostrictive material coating strip 2 is divided into a positive giant magnetostrictive material coating strip 2a and a negative giant magnetostrictive material coating strip 2b, and the positive giant magnetostrictive material coating strip 2a and the negative giant magnetostrictive material coating strip 2b are equally spaced It is applied obliquely on the measured rotating shaft 1 symmetrically along the axial direction; the left and right ends of the measured rotating shaft 1 are respectively nested in the inner holes of the left bearing 3a and the right bearing 3b, and the left bearing 3a and the right bearing 3b Nested respectively at the left and right ends of the shaft sleeve 4, the inner wal...

Embodiment 2

[0049] refer to figure 1 In this embodiment, on the basis of Embodiment 1, the positive giant magnetostrictive material coating strip 2a is coated on the measured rotating shaft 1 with an axial tilt of ﹢45°, and the negative giant magnetostrictive material The coating strip 2b is coated on the measured rotating shaft 1 inclined at -45° in the axial direction.

Embodiment 3

[0051] refer to figure 2 In this embodiment, on the basis of the first embodiment, the lengths of the left measuring coil 6 a and the right measuring coil 6 b along the axis are set equal to 1 / 2 the length of the excitation coil 5 along the axis.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com