Dry multi-piece friction electromagnetic disc type power-off brake

A technology of power-off brakes and electro-magnetic disks, applied in the types of brakes, brake components, brake actuators, etc., can solve the problems of poor brake heat dissipation, shortened service life, hidden safety hazards, etc., to speed up heat dissipation and prolong Service life, the effect of avoiding accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

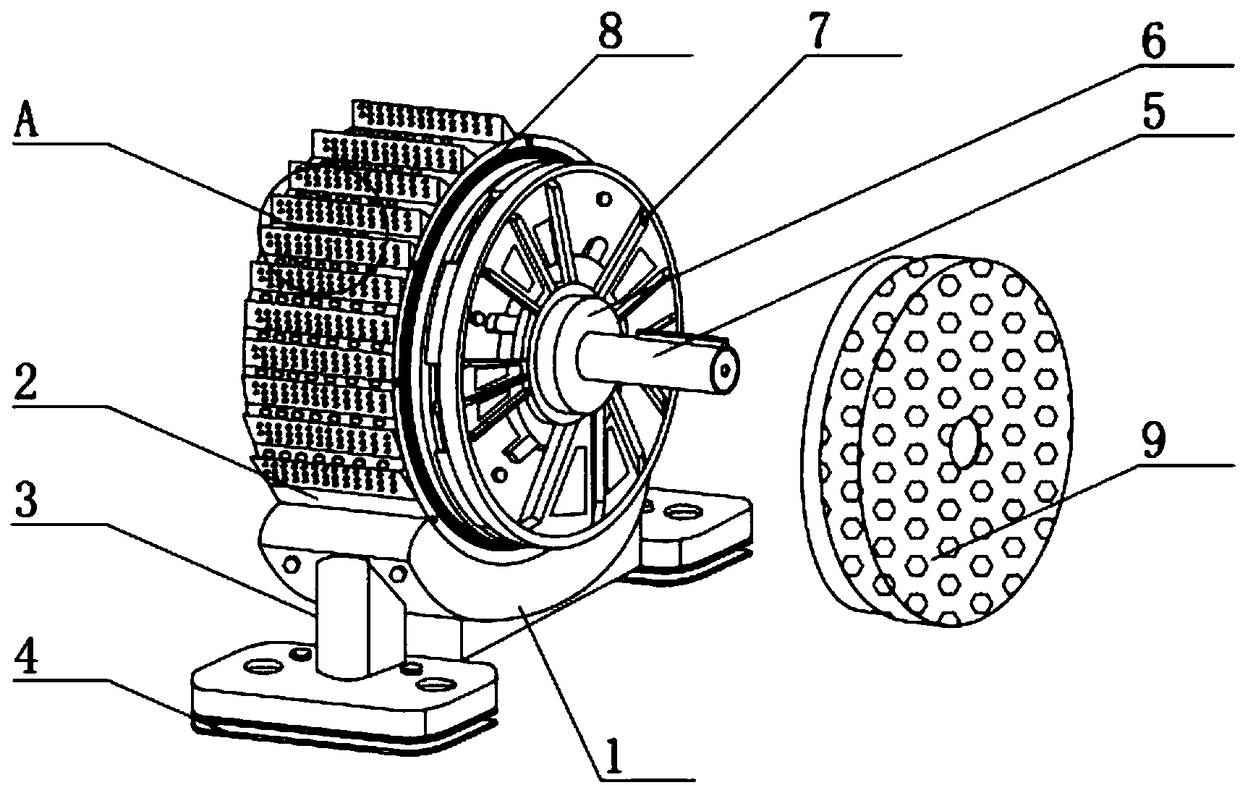

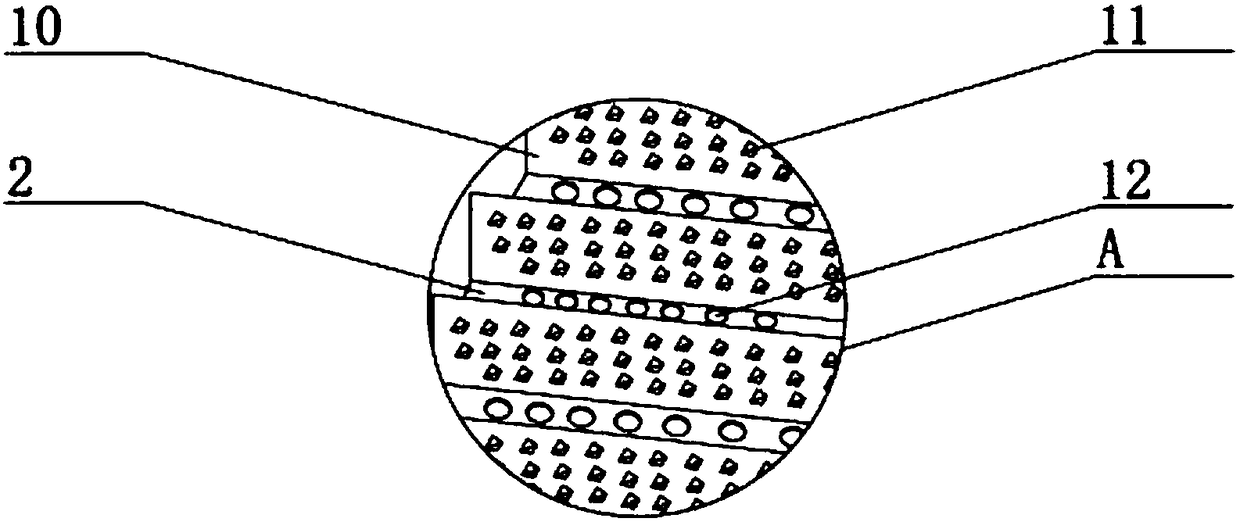

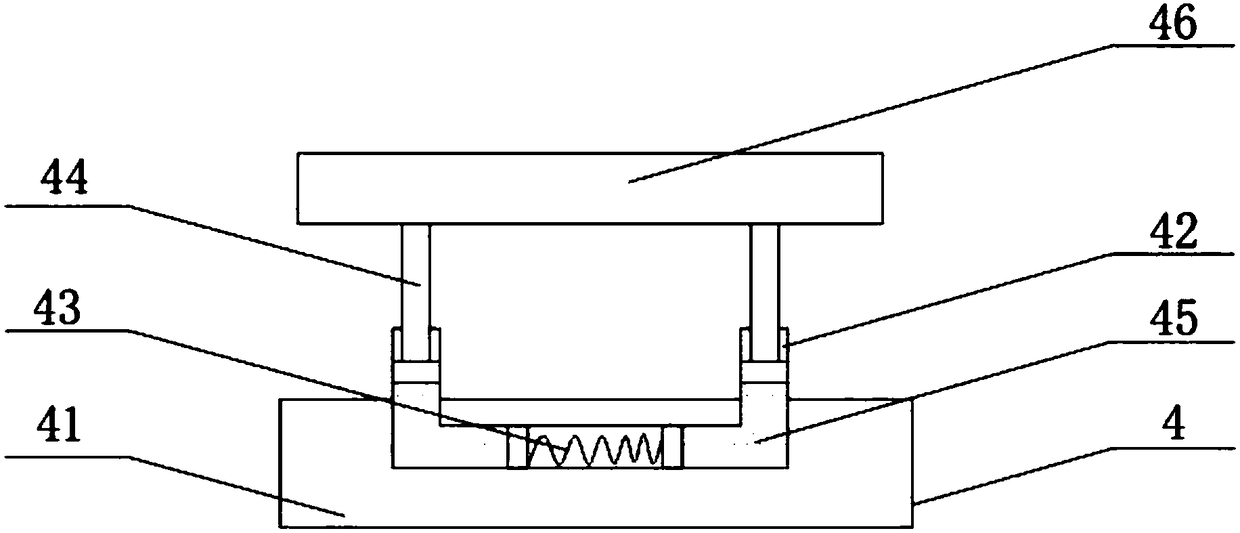

[0020] Such as Figure 1-Figure 4 As shown, the present invention proposes a dry-type multi-disc friction-electromagnetic disk-type de-energized brake, which includes a brake body 1, a mounting base 3 is provided at the bottom of the brake body 1, and a shock absorbing device 4 is fixedly installed on the lower surface of the mounting base 3. , the damping device 4 comprises a first damping plate 41, the inside of the first damping plate 41 is fixedly installed with a shock absorber 42, the inside of the shock absorber 42 is provided with a damper spring 43, and the two ends of the damper spring 43 The baffles are fixedly installed, the top of the shock absorber 42 is installed with a pressure bearing rod 44, and the hydraulic oil 45 is arranged between the pressure bearing rod 44 and the baffle plate, and the top of the pressure bearing rod 44 is fixedly installed with a second shock absorber. The plate 46 acts as a shock absorber. By setting the shock absorber 4, the impact ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com