Light medium high-energy head compressor model stage with flow coefficient being 0.0264 and design method

A flow coefficient and compressor technology, applied in the field of compressors, can solve problems such as unfavorable rotor stability, difficult product design, and low efficiency of the stage, and achieve the effects of high-energy head coefficient, small span, and large wheel-to-hub ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

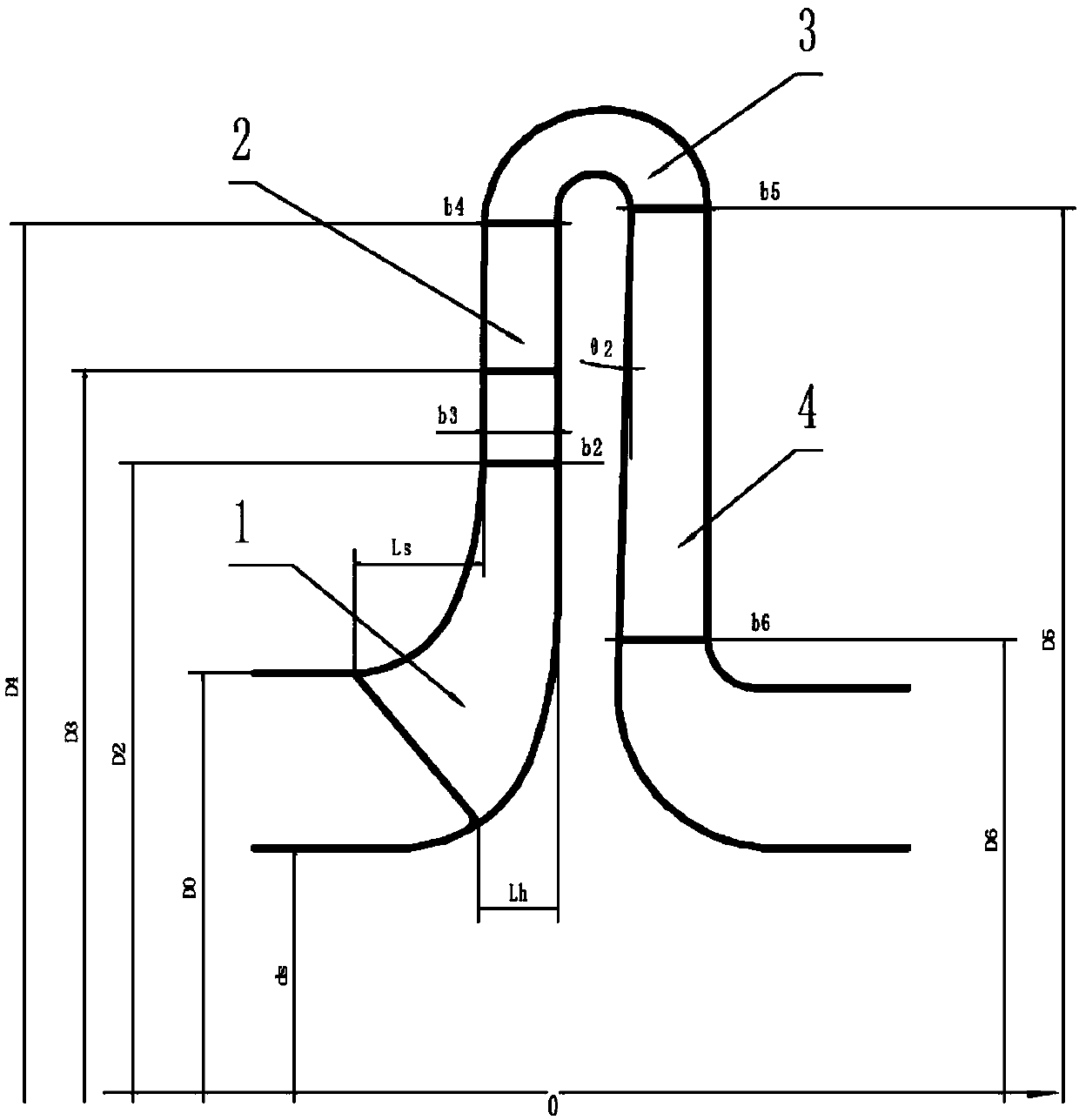

[0036] see figure 1 , a light medium high-energy head compressor model stage with a flow coefficient of 0.0264 provided by the embodiment of the present invention is suitable for the modular design of light medium compressor products, including impeller 1, vane diffuser 2, bend 3 and reflux device 4 , where the impeller 1 is located at the inlet of the model stage, the outlet of the impeller 1 is provided with a vane diffuser 2, and the reflux device 4 is located at the outlet of the model stage, and the vane diffuser 2 and the reflux device 4 are connected by a bend 3 Pass. The machine Mach number M that can be used by this model level a2 =0.2-0.65, design point flow coefficient Φ 1 =0.0264, the design point energy head coefficient τ=0.71, the variable efficiency η under the design flow coefficient working conditions at each Mach number pcl =0.8515, the applicable flow range is 0.71~1.37 of the design point. Specific performance curves such as Figures 16-18 shown.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outlet diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com