Laboratory fume hood glass door guide rail mechanism and device

A technology of glass guide rails and fume hoods, applied in the field of laboratory equipment, can solve the problems of out-of-synchronization of opposite guide rails, inconvenient installation and maintenance, and large motion friction coefficient, so as to achieve good energy saving effect, reduce motion friction coefficient, and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

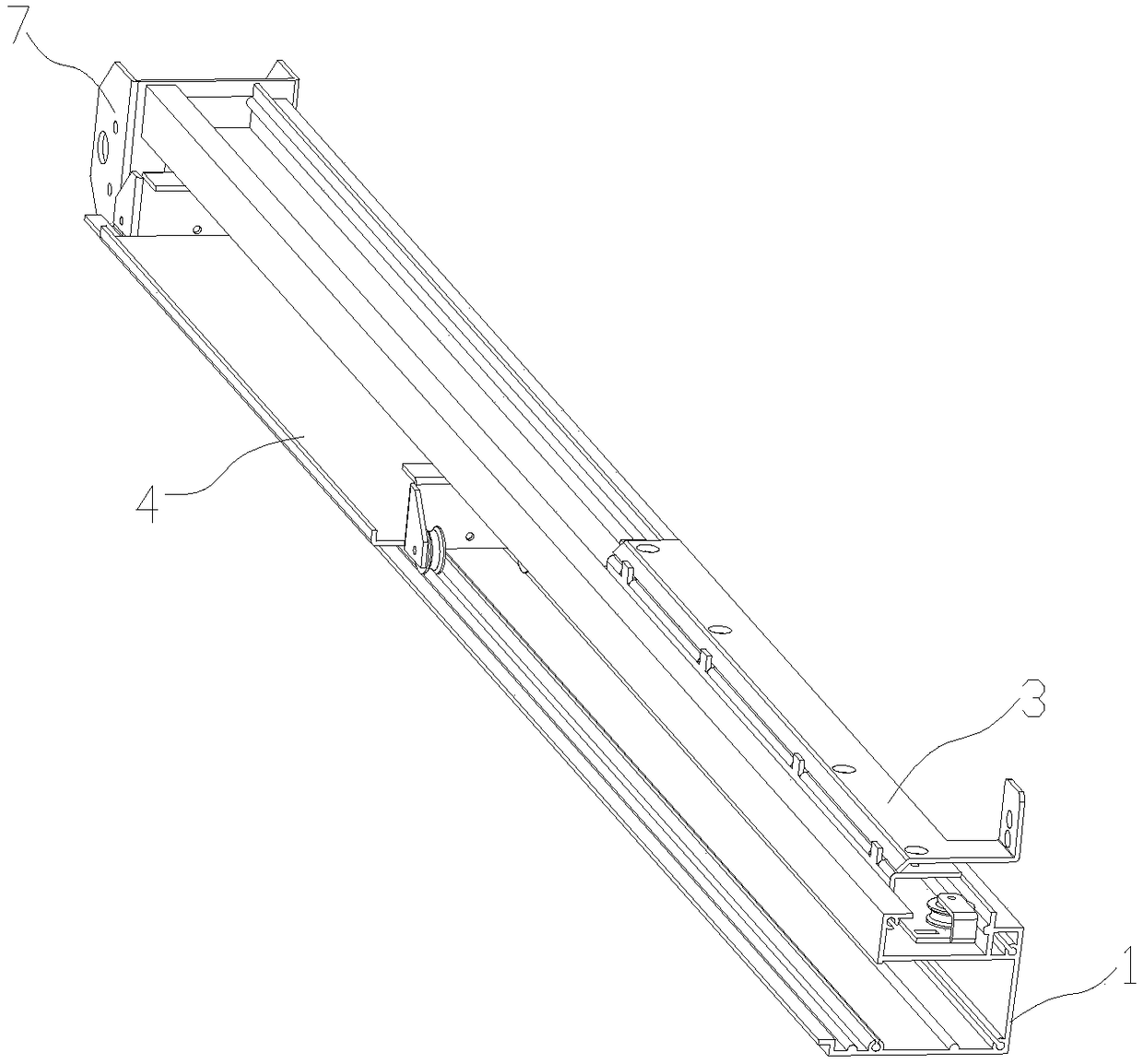

[0030] refer to Figure 1-4 As shown, the laboratory fume hood glass door guide rail mechanism provided in this embodiment includes a guide rail main body 1 , a glass guide rail splint 2 , a glass pressure plate 3 and a counterweight box 4 .

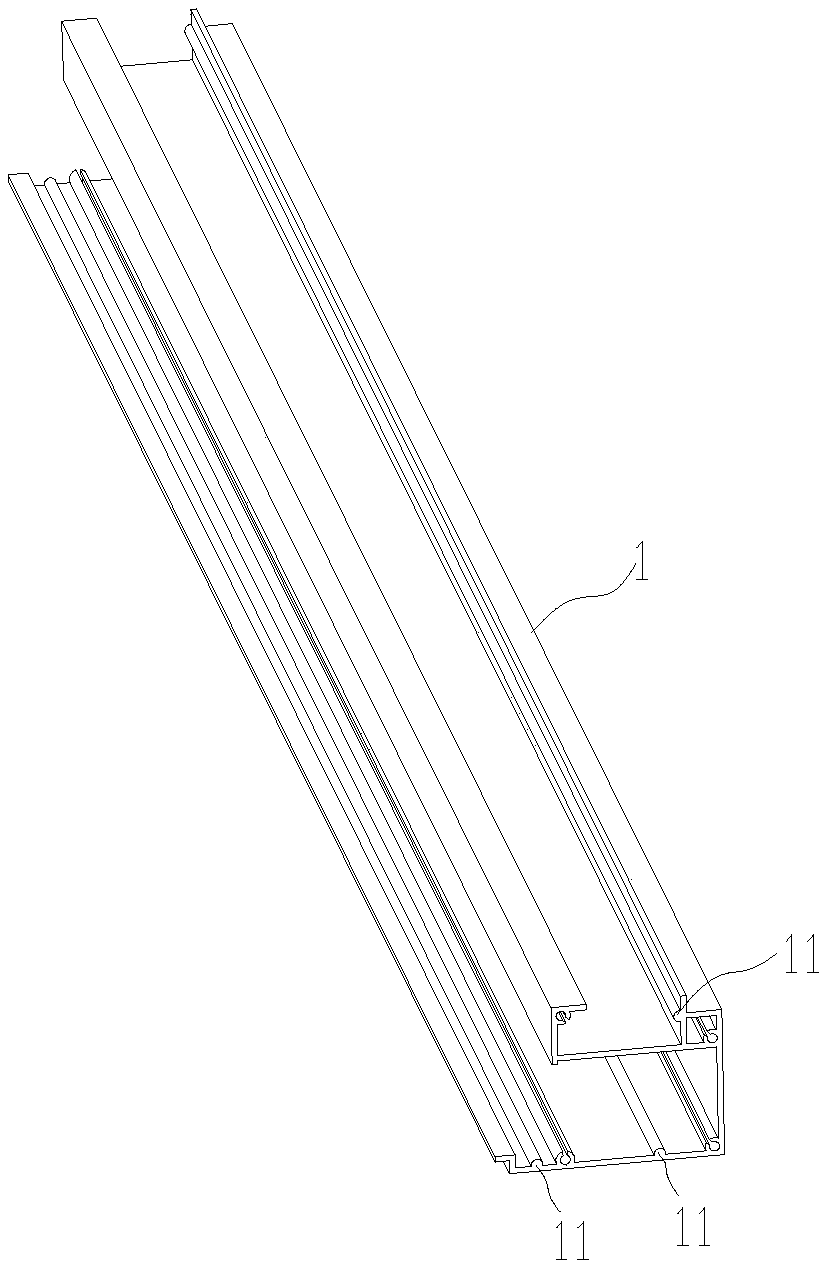

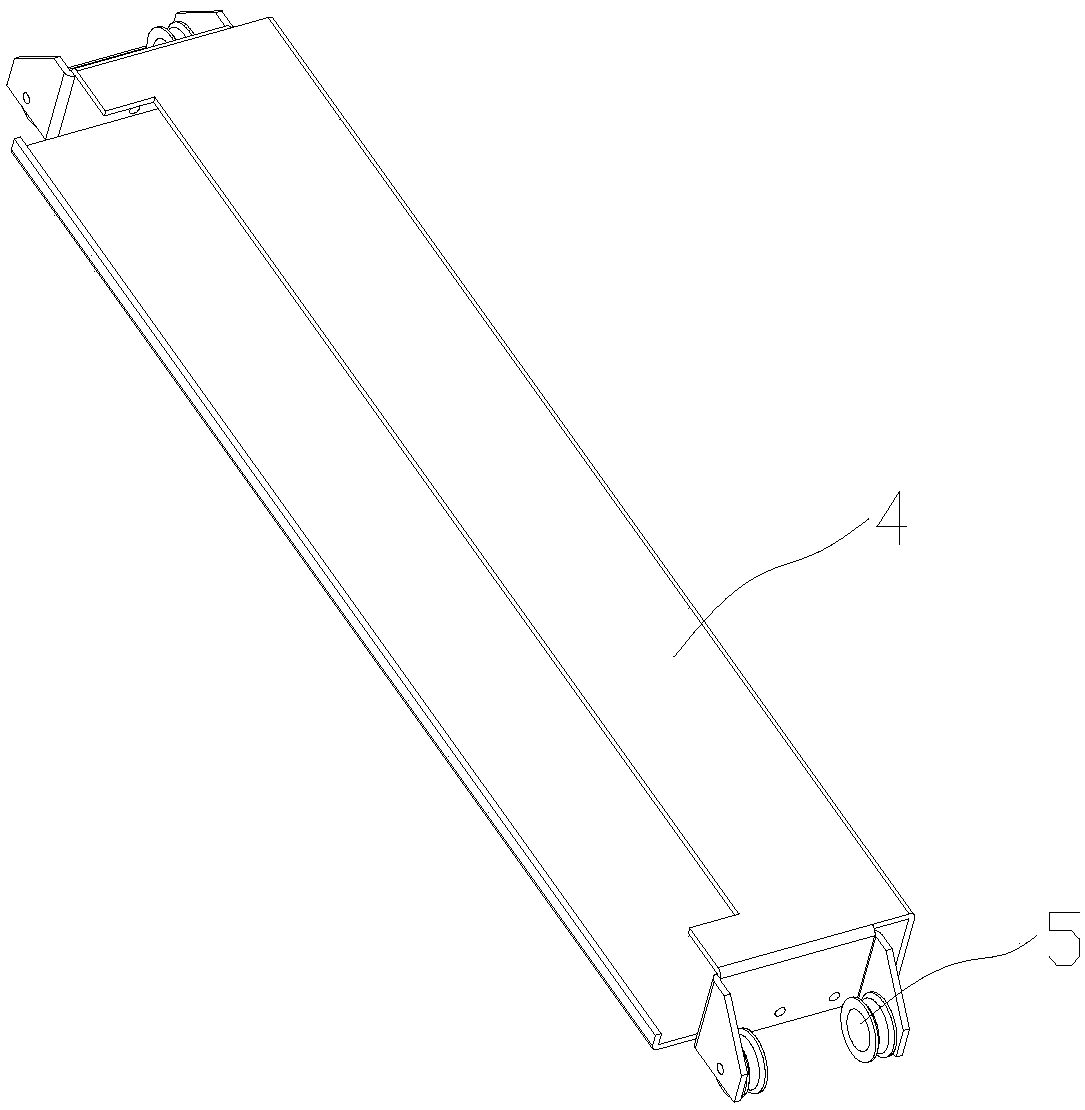

[0031] Among them, such as figure 2 As shown, the main body 1 of the guide rail is a double-layer structure, formed by integral die-casting, and has a compact structure, which can effectively reduce the process steps in the installation process, save installation time, and improve production efficiency; Along the length direction of the bottom panel, two guide strips 11 are arranged parallel to each other at intervals, and one guide strip 11 is arranged on the side panel of the upper layer of the guide rail body along the length direction of the side panel. The front and rear ends of the counterweight box 4 are correspondingly equipped with two guide wheels 5 and are cooperatingly installed in the guide strips 11 on the bottom panel, s...

Embodiment 2

[0038] refer to Figure 5 Shown is the laboratory fume hood glass door guide rail device provided in this embodiment, which includes the laboratory fume hood glass door guide rail mechanism 100 in Embodiment 1, the connecting shaft 10 , the synchronous belt and the synchronous wheel 9 . Wherein, the glass door guide rail mechanism 100 of the laboratory fume hood is relatively arranged on the left and right, the glass door is nested and installed in the glass nesting installation positions of the two guide rail mechanisms, and the two ends of the connecting shaft 10 are respectively installed on the glass doors of the two laboratory fume cabinets. In the bearing block 8 of the guide rail mechanism, the synchronous wheel 9 is installed on the two ends of the connecting shaft 10 and is located in the guide rail mounting bracket 7, and the counterweight box 4 is connected and driven by the synchronous belt and the synchronous wheel 9. In this way, by using the synchronous wheel 9,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com