Flexible bag type extruding and rolling type full-automatic washing machine and washing method thereof

A fully automatic washing machine and flexible bag technology, applied in the field of washing machines, can solve the problems of high cost, difficult miniaturization, easy to retain dirt, etc., and achieve the effects of low cost, good for cleaning and sanitation, and simplified design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

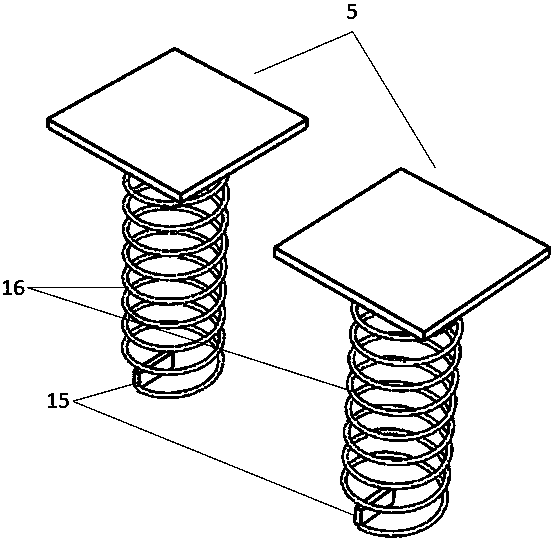

[0032] In Fig. 1, the laundry bag supporting device 5 is composed of two parts, corresponding to the front and rear parts of the flexible laundry bag 6, respectively. The pressure sensor 15 is located at the lower part of the buffer 16 . The main components of the buffer can usually be springs, airbags and other devices with motion buffering functions. The pressure sensor 15 judges whether there is clothing in the bag by the pressure transmitted to the buffer 16 by the flexible laundry bag 6 when the washing machine is running, and at the same time, according to the relative installation position of the pressure sensor 15 in the washing machine, the capacity of the corresponding laundry bag can be determined (The relative installation positions of laundry bags of different capacities in the washing machine are known); the buffer 16 can provide stroke space and cushioning for the compression of the flexible laundry bag 6 .

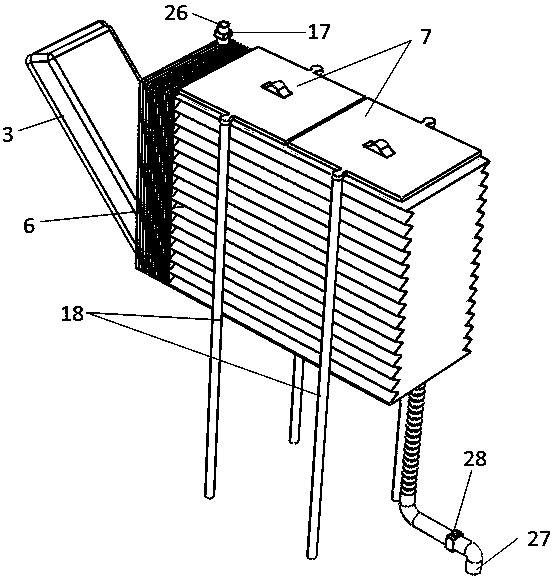

[0033] In Fig. 2, the piston 7 is located at the top...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com