Pavement brick

A technology of pavement bricks and weight units, which is applied in the field of pavement bricks, can solve the problems of no unified test procedures for soil curing agents, and difficulties in the research and comparison of soil curing agents, and achieve the effects of saving costs, avoiding ecological damage, and simple production methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

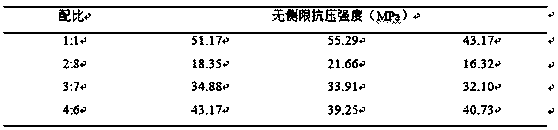

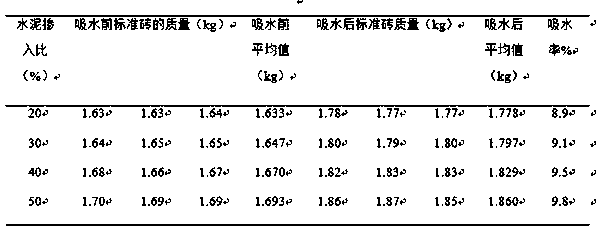

Method used

Image

Examples

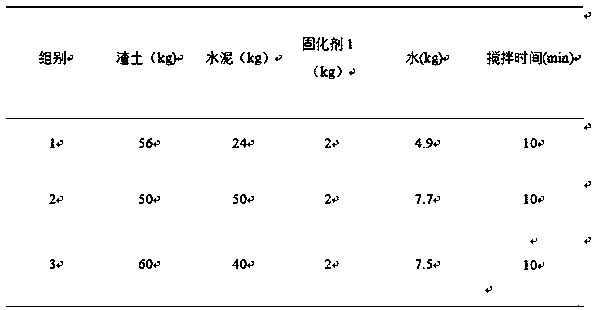

Embodiment 1

[0028] Pavement bricks are composed of the following weight units (kg): muck 50, cement 50, curing agent 2, water 7.7.

[0029] The pavement bricks are obtained by mixing, stirring, molding, and curing the raw materials in the above weight units, wherein the stirring time is 10 minutes, the molding is pouring vibration molding, and the curing is wake-up spray curing after final setting, and the curing The period is not less than 28 days.

Embodiment 2

[0031] Pavement bricks are composed of raw materials in the following weight units (kg): muck 56, cement 24, curing agent 2, water 4.9.

[0032] The pavement bricks are obtained by mixing, stirring, molding, and curing the raw materials in the above weight units, wherein the stirring time is 10 minutes, the molding is pouring vibration molding, and the curing is wake-up spray curing after final setting, and the curing The period is not less than 28 days.

Embodiment 3

[0034] Pavement bricks are composed of the following weight units (kg) of raw materials: muck 60, cement 40, curing agent 2, water 7.5.

[0035] The pavement bricks are obtained by mixing, stirring, molding, and curing the raw materials in the above weight units, wherein the stirring time is 10 minutes, the molding is pouring vibration molding, and the curing is wake-up spray curing after final setting, and the curing The period is not less than 28 days.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com