Air pressure corner pantograph and monitoring system and monitoring method

A technology of pantograph and corner, which is applied in collectors, electric vehicles, power collectors, etc. It can solve the problems of large investment and a large number of detection points, and achieve the effects of simple control method, avoiding accidents, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without creative efforts fall within the protection scope of the present invention.

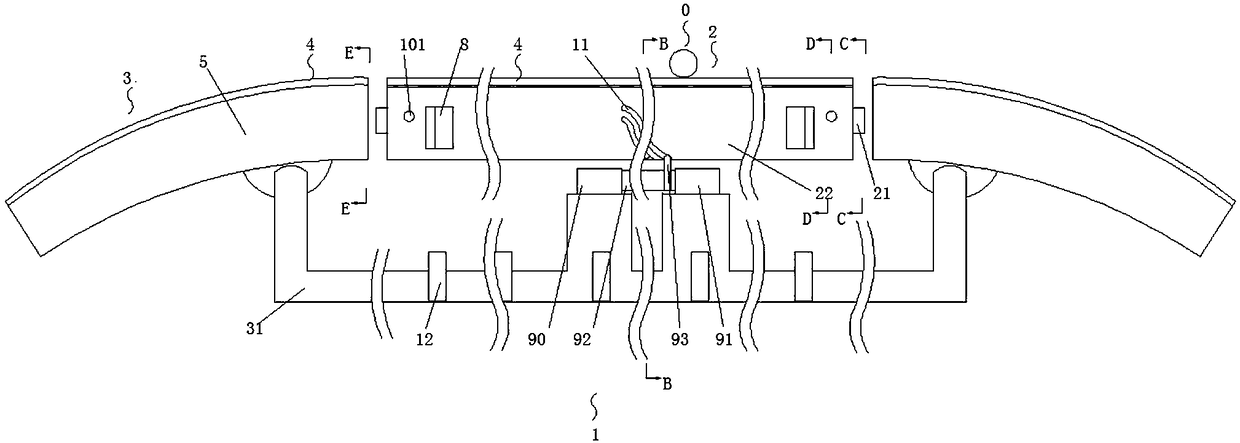

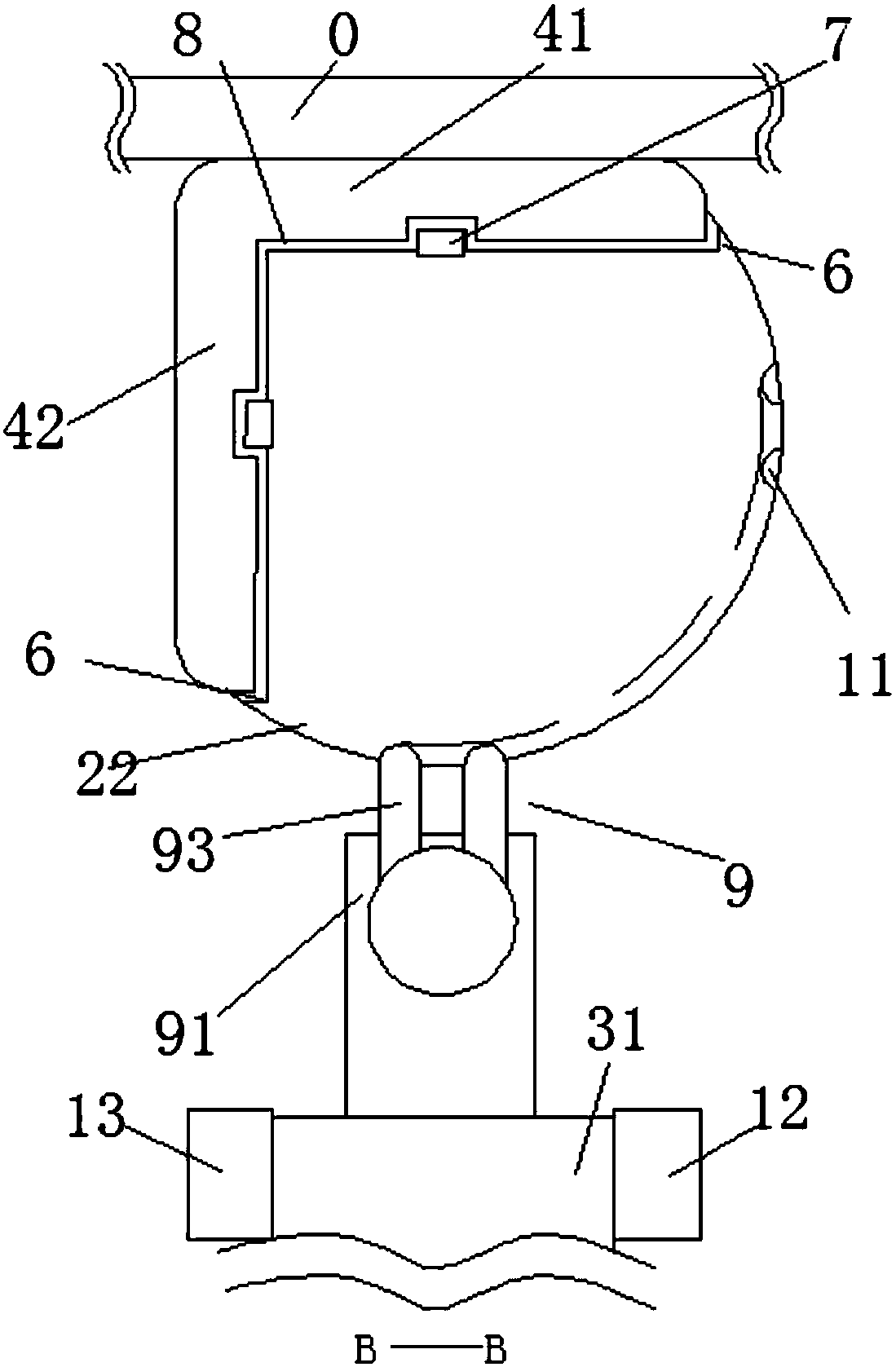

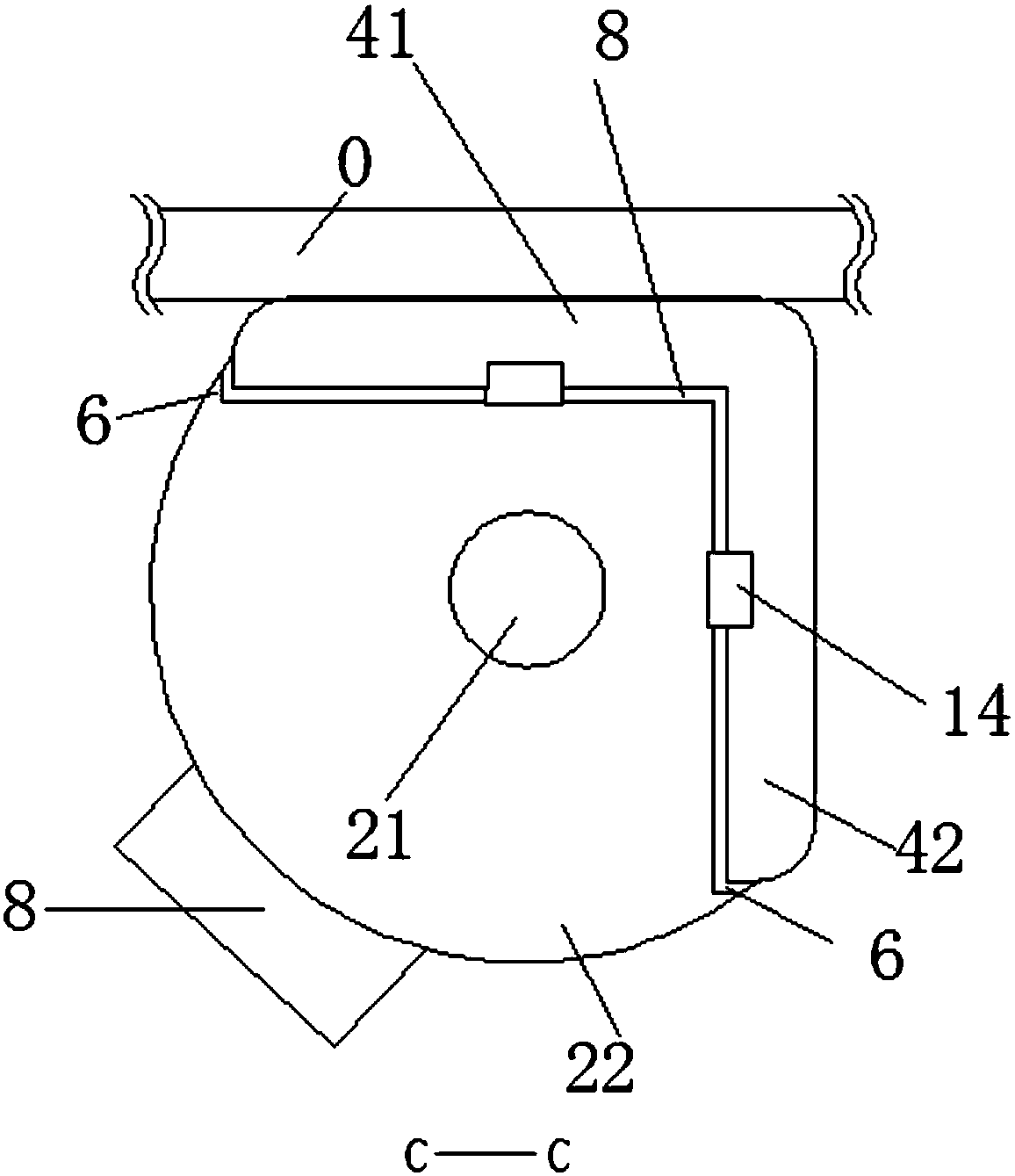

[0035] An air pressure angle pantograph and its monitoring system, such as figure 1It is a top view of a working state of the pantograph 1, including the action section 2 of the pantograph 1 in the middle and the arc sections 3 on both sides. The arc section 3 is installed on the bracket 31, and the action section 2 extends through the center of both ends The rotating shaft 21 is rotatably connected with the arc section 3, the upper part of the action section 2 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com