PVC pine needle shearing and shaping all-in-one machine

An all-in-one machine and pine needle technology, applied to household components, household appliances, and other household appliances, can solve problems such as unqualified products, increased processing costs, and product size errors, so as to save electricity consumption, save energy and protect the environment, and improve The effect of production efficiency and safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

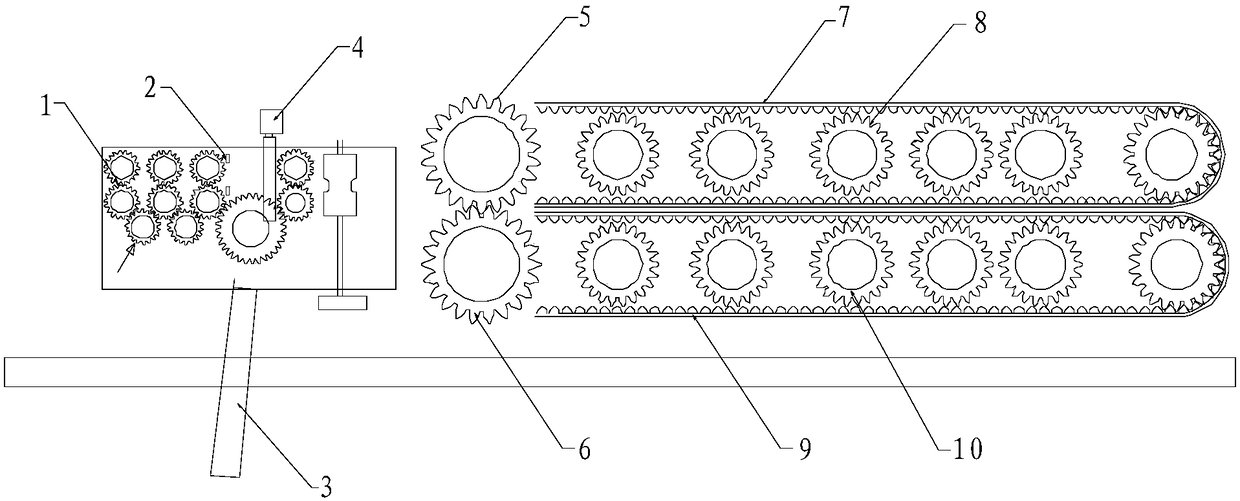

[0024] Such as figure 1 As shown, a PVC pine needle shearing and shaping machine includes a feeding device 1, an optical fiber detection device 2, a cutting device 3, a heating device 4 and a rolling output device. The feeding device 1 is used to transport materials, and its feeding outlet is provided with The optical fiber detection device 2, the optical fiber detection device 2 is used to detect the fixed point of the material, the cutting device 3 is located at the detection fixed point of the optical fiber detection device 2, and is used to cut off the redundant pine needles of the material, and the heating device 4 is set On the side of the shearing device 3 away from the optical fiber detection device 2, it is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com