Unloading collection device for factory

A collection device and factory technology, applied in metal processing, etc., can solve the problems of inability to store functions, inability to ensure dryness of workpieces, unfavorable energy saving, etc., and achieve the effect of ensuring dryness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

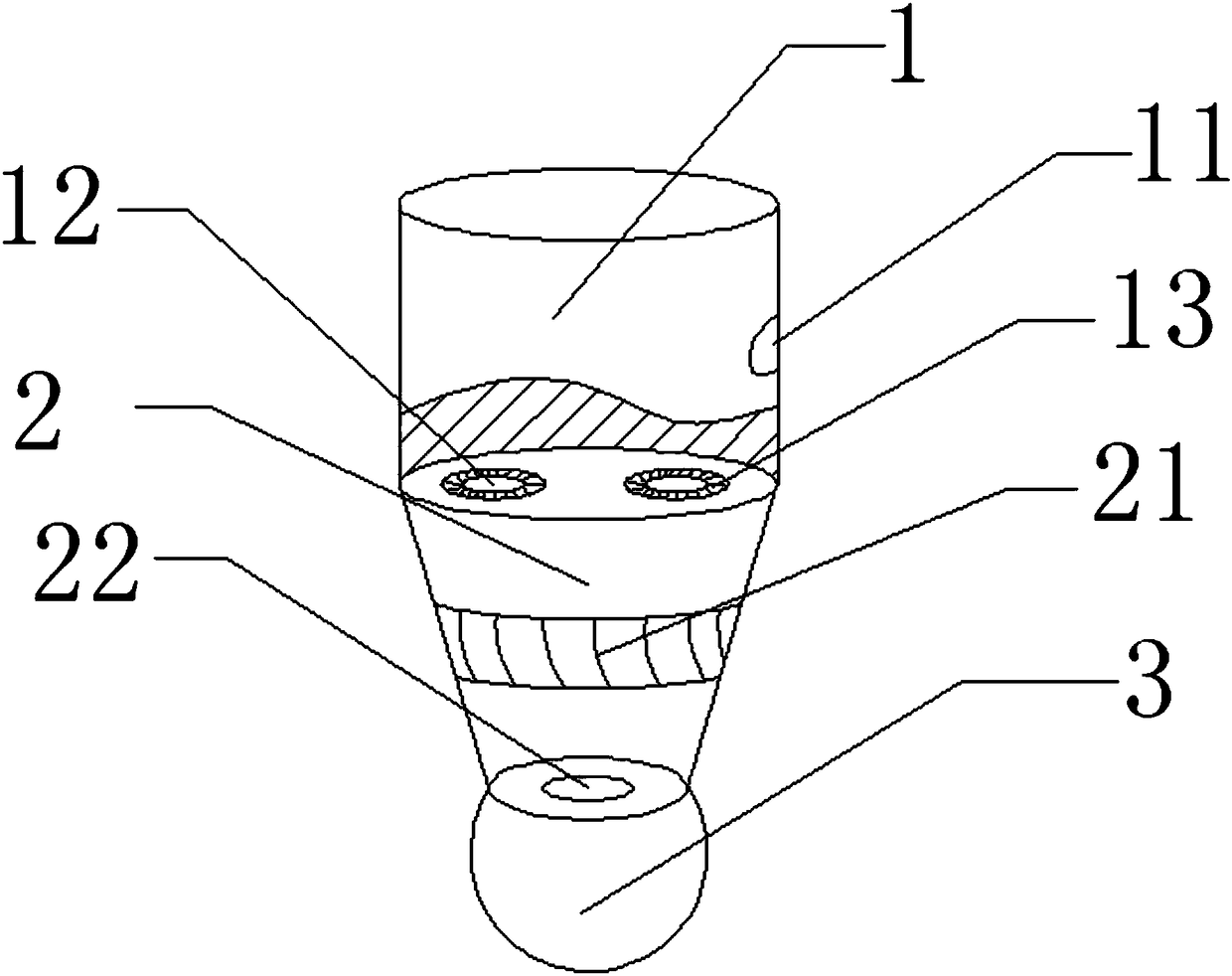

[0018] Such as figure 1 As shown, a factory unloading collection device of the present invention includes a storage bin 1 provided with a feed inlet 11 on the side end surface, the lower end of the storage bin 1 is connected with the processing bin 2, and the storage bin 1 and the processing bin 2 are connected There is a discharge port 12, an exhaust fan 21 is provided on the side end surface of the processing bin 2, and a collection bag 3 is provided on the lower end surface of the processing bin 2. The processing bin 2 opens the discharge port 22 to put the internal materials into the collection bag 3 within. Two bins are provided to perform partial operations. The upper storage bin is used to temporarily store the workpieces. When processing is required, the discharge port is opened, and the workpieces are placed in the lower processing bin, through the exhaust fan on the processing bin, Reduce the humidity in the processing chamber to ensure the dryness of the workpiece, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com