Pipeline connector structure convenient to replace and maintain

A technology for pipe joints and joints, which is applied in the direction of pipes/pipe joints/fittings, threaded connections, pipe components, etc. It can solve the problems of easy blockage and cleaning of pipes, low work efficiency, single function, etc., and achieves easy replacement and maintenance. Easy maintenance, good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

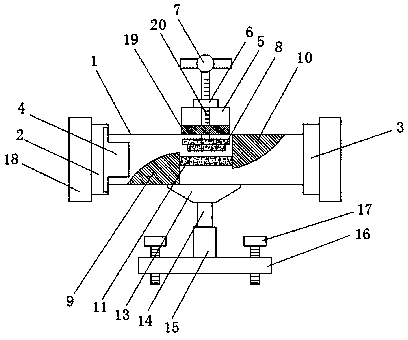

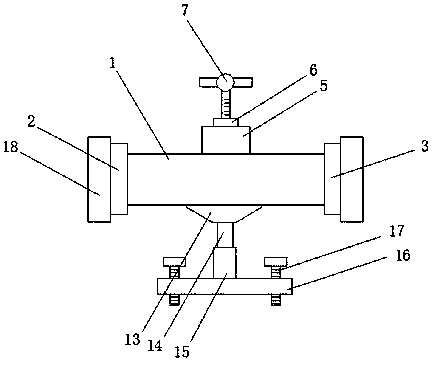

[0017] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0018] Such as Figure 1-Figure 3 As shown, a pipe connector structure that is easy to replace and maintain, includes a connector body 1, the two sides of the connector body 1 are respectively provided with a water inlet 2 and a water outlet 3, and the inner cavity of the water inlet 2 is installed with a filter Cover 4, by setting the filter cover 4, impurities in the water can be filtered to prevent the pipeline from being blocked. The top of the connector main body 1 is fixed with a sealing cylinder 5, and the top surface of the sealing cylinder 5 is inlaid with a first fixing nut 6. The first fixing nut 6 is threadedly connected with a T-shaped threaded rod 7, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com