Lifting tool for lifting with adjustable transmission shaft

A transmission shaft and hoisting technology, which is applied in the field of spreaders, can solve the problems of affecting the production process, poor adaptability, and falling off of the transmission shaft, and achieve the effect of adjustable space size, strong adaptability, and stable lifting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solution of the present invention will be further specifically described below in conjunction with the accompanying drawings.

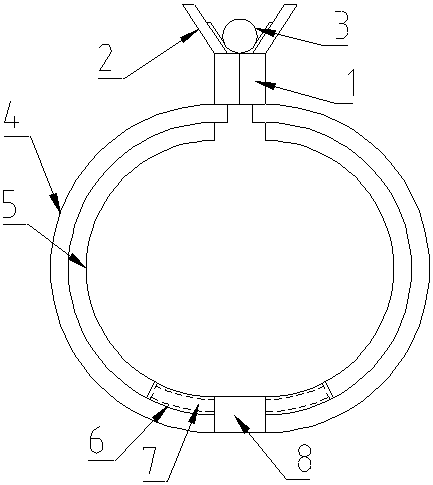

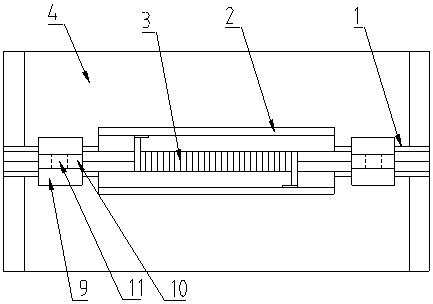

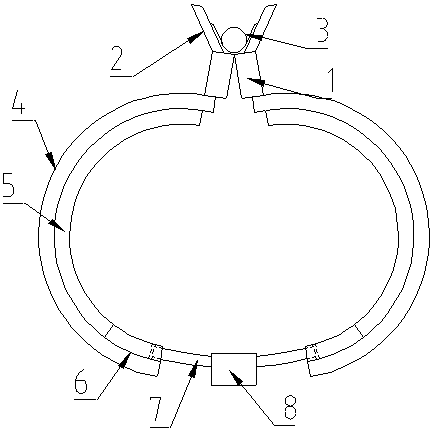

[0016] Such as figure 1 , figure 2 , image 3 As shown, a hoisting tool for adjustable transmission shaft, including movable plate 1, splint 2, torsion spring 3, connecting hoop 4, buffer layer 5, cavity 6, guide rod 7, connecting block 8, hanging base 9 , hanging plate 10 and hanging through hole 11.

[0017] Wherein, the movable board 1 is two vertical boards parallel to each other. Preferably, the tops of the two movable boards 1 are connected together by a hinge, which is convenient to use. The movable board 1 is provided with a V-shaped splint 2, preferably , the movable plate 1 and the splint 2 are set in an integrated structure, which makes the whole device more durable, a torsion spring 3 is arranged between the splints 2, and a semicircular connecting hoop 4 is fixedly connected to the bottom of the movable plate 1, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com